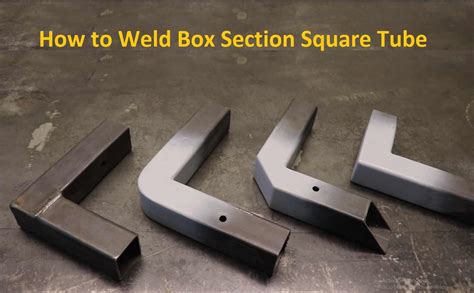

weld a steel box So if you're into grinding, welding, fabricating, etc, you're in the right place! Here's some tips on cutting, welding and finishing steel box corners to a seamless finish. Merchandise: http. $88.23

0 · welding box section corners

1 · square tube 90 welding

2 · metal shop box welding

3 · metal shop box project

4 · metal box welding project

5 · metal box welding

6 · how to weld box corners

7 · how to mig weld a box

$16.99

So if you're into grinding, welding, fabricating, etc, you're in the right place! Here's some tips on cutting, welding and finishing steel box corners to a seamless finish. Merchandise: http. In this video I came up with a simple and fun project for the beginning welder like me, to practice welding. We'll be using Mig welding to make a basic Metal.Step 1: Get Materials. You will need: 1. Thin steel. I used 1/8" steel from a local scrap yard. The amount depends on the size of box you want. 2. MIG welding equipment. 3. Plasma cutter or .

electrical outlet box adapter plate

A welded box steel column is a structural member that is made by welding together four pieces of steel plate to form a box-shaped cross-section. The web and flanges of the column are typically made of the same material . All include their respective steel welding gate lock boxes for exterior use.100% quality backed purchase. Toledo Locks offers customers superior quality locks made under strict manufacturing specifications to ensure .

The Box Beam Welder is an automated welding machine that is fully customisable and designed for joining heavy-duty structural steel box section fabrications, perfectly suited for the oil & gas and civil construction industries. The machine . A weld is used to join parts together by melting the materials and causing fusion. In the GIF above a MIG welder is being used to weld the two metal components together. A MIG welder has filler material which deposits material between the two parts. This leaves behind a bead of weld that looks like this: We can see welds like this everywhere we . It’s advisable to perform carbon steel welding and stainless-steel welding in separate areas entirely. . This is one of the most common joints in welding and is used to create outer edges, boxes, box frames, and similar. Butt Welding Joint. Butt welds, also known as square groove welds, are used to attach two components at their narrowest .

Buy Speedway Motors Custom Weld-On Remote Mount Car Battery Relocation Box/Steel Tray, Universal Fit, Durable 16-Gauge Steel, Natural Finish, 11" x 9.5" x 6.63": Trays - Amazon.com FREE DELIVERY possible on eligible purchases The best way I can thing to do this is to run conduit down the face of the post to a metal handy box in which to place the switch. Other than trying to drill through steel, the best solution I can come up with to mount the box is J-B Weld. The stuff is strong, withstands high temperatures (up to 600 degrees) and is not electrically conductive .

The welding wire and flux used in automatic welding or semi-automatic submerged arc welding should be compatible with the strength of the base metal. All welding rods must have a certificate of conformity. The matching of welding materials with the parent metal should meet the design requirements and the current national industry standards; 2.3 .Explore WelderMade's Scrap Boxes for unique metal pieces perfect for your projects. Find a variety of high-quality scraps to fuel your creativity and add character to your welding creations Never had any problems with the weld cracking on the mild steel plate. Now cast iron would be another issue.Bob Bob Wright. Comment. Post Cancel. rodsfabworks. Junior Member. Join Date: Dec 2008; Posts: 5; Share Tweet #4. 12-10-2008, 10:32 AM. Thanks for the advice I will try it.Rod Comment. Post Cancel. Sberry .Custom Metal Planter Boxes: Elevate Your Space Enhance your outdoor living area with a custom metal planter box. Crafted with durable materials like steel, aluminum, or copper, these planters offer a modern, sleek aesthetic that complements various architectural styles. Key benefits of custom metal planter boxes: Durability: Built to withstand the elements, these planters are long .

Are you mixing Steel and Aluminium? If so, go for bolting or riveting (and check the potential for galvanic corrosion). If it's either steel or aluminium, and just one box: Steel - I'd weld. Any hobbyist shop can weld steel. Aluminium - I'd bolt or rivet. Welding . Stick is simple and easy to use, but it does produce a lot of spatter. On stainless work, that can be a problem. So, you may want to have some anti-spatter gel or spray on hand to prep the workpiece before welding. Preparing stainless steel for welding. After setting up your welder for stainless steel, you now need to prepare the metal before .

4. Corner Joint with Double Fillet Weld: Uncompromised Strength for Structural Integrity. When structural integrity is paramount, the corner joint with a double fillet weld technique is the go-to choice. This method involves notching the ends of the square tubes to create a 90-degree corner joint with a small gap between them.

Check out this DIY planter box build, which is a perfect welding project for beginners or students. ****Affordable self-paced welding courses taught by me***. The new type HSS exhibits a low m of approximately 0.86, and an δ is greater than 16%, which meets the seismic performance design requirement in the JGJ/T 483–2020 [28].The chemical composition of HS80GJ welding wire is also presented in Table 1, and the test specimens were processed by submerged arc welding, and followed by post-weld heat treatment.using 11 ga stainless steel, that was water jet cut. my friend Roy shows how he uses a #12 furick cup and chill bars to get great argon shielding on this small argon purge box. An argon purge box is used not only for titanium parts, but .

2 different sizes available small box has inside dimensions of 8 7/8" wide x 7 1/4" deep large box has inside dimensions of 11" wide x 7 1/4" deep lightweight steel construction includes aluminum clamp bar, 2 j-bolts, & 2 jam nuts . battery boxes, weld-on The weld component plays a critical role in the force chain model of welded built-up steel box columns. The weld needs to serve as a force control element rather than a ductile element. In other words, the weld should primarily handle the transfer of forces and maintain structural stability, .2,430 Mig Steel Welding jobs available on Indeed.com. Apply to Fabricator/welder, Welder, Mig Welder and more! Skip to main content . Employers / Post Job. 1 new update. Start of main content. Keyword : all jobs Edit location input box label. Search. Date posted. Last 24 hours; Last 3 days; Last 7 days; Last 14 days; Remote. Hybrid .

Sheet Metal Box: This is a great project to make if you are new to working with sheet metal. At this point in my class all of our sheet metal projects have been very simple with, at most, one bend. . When you spot weld the box together you want as clean of connection between the metal as possible. That means before you start doing any bending .Weldable Gate Box - fits 3 popular locks – Kaba Simplex 1000 and 5000 series, AlarmLock Trilogy, and CodeLocks 5000 series. . Weld Box fits the Von Duprin 99 Exit Device Product Details: Width: 5” Height: 15” Depth: 1-3/4” Type: Panic Hardware 14 Gauge Steel Download Product Brochure Download Cross Reference by Lock Manufacturer and . Join Jeff Ray as he shows you all the information you need on TIG welding your own Header.Ready to join the WELD™ community? Download the app in the Google .

Detailing Metal workshop and site fabrication welding. Mig welding GMAW Stick welding Steel work Metal work Structural steel work WorkshopSteel Fabrication.

Speedway Motors Custom Weld-On Remote Mount Car Battery Relocation Box-Steel Tray Universal Fit, Durable 16-Gauge Steel, Natural Finish, 11 x 9.5 x 6.63 I recently purchased the Speedway Motors Custom Weld-On Remote Mount Car Battery Relocation Box and I am beyond impressed with its durability and functionality. Weld in steel to fill the gap between the door frames, pour the sides and top, weld on the top cover. I'd weld the inner with the Mig, the outer with 6011 on DCEP. In both cases, tack it together, then run short beads (1" or so) 5-6" apart, then fill in. Avoid getting it too hot and warping it by welding in sections with time to cool in between.

Detailing Metal workshop and site fabrication welding. Mig welding GMAW Stick welding Steel work Metal work Structural steel work WorkshopSteel Fabrication.

welding box section corners

I have a product that is designed to be installed to a wall recessed junction box; this approach can not be accomplished for my installation. I'm looking to do a wall mount JB that will support a fixture and will run exposed conduits from JB to JB to provide power to the lights.

weld a steel box|how to mig weld a box