electrical box rough in To clarify, roughing in as an electrician refers to pulling wring, drilling holes, mounting box heights for receptacles and light switches, or bending emt pipe, building pipe racks, building an electrical room, or even looking at . Willy's Custom Metal, established in 2015 by William "Brian" Richards, is a custom fabrication and welding shop serving the Greater Sacramento Area to the Bay Area and beyond. Brian is an AWS certified structural steel contractor with a creative eye and exceptional attention to detail and customer service.

0 · roughing in electrical outlets

1 · rough in electrical wiring layout

2 · rough in electrical wiring diagram

3 · residential electrical rough in checklist

4 · residential electrical rough in

5 · electrical rough in material list

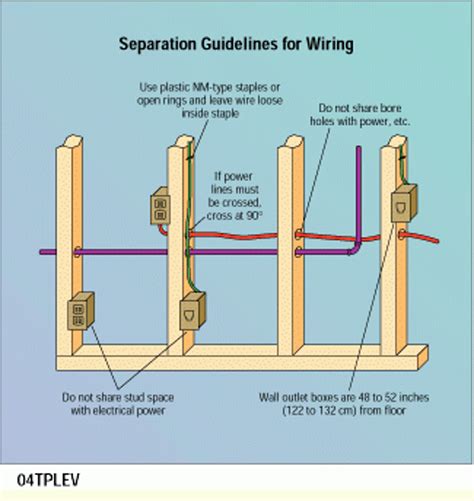

6 · electrical rough in inspection guidelines

7 · electrical rough in check list

Follow specific steps to install a window A/C unit in a metal building, including attaching brackets and using sealing foam. Maintain your air conditioner by regular cleaning, inspection, ventilation, professional service, and thermostat setting.

Part of an electrician’s job is setting boxes so they’ll be flush to finished surfaces. Before an electrician starts working, modifications to the framing—such as furring out or planing down irregular studs and ceiling joists—must be complete. Wire Strippers https://amzn.to/3e6jq2UIn this video I will show you how to install rough in electricity in a new construction house. This is how to do wire a. Standard electrical rough-in materials include various sizes of electrical wires to carry different loads, electrical boxes to house outlets and . Metal fatigue can result in scored or broken conductors, which in turn can cause short circuits, heat buildup, and in the worst cases, fire. Installing a safe electrical system is a huge responsibility that guides our work at rough-in .

To clarify, roughing in as an electrician refers to pulling wring, drilling holes, mounting box heights for receptacles and light switches, or bending emt pipe, building pipe racks, building an electrical room, or even looking at .

Most of the materials installed during the rough-in phase can be installed either in new construction or remodel wiring. All materials must be UL- or NRTL-listed, which indicates that they meet the safety standards of the electrical industry. Knowing how to rough in electrical wiring ensures that the foundational electrical work is done correctly, paving the way for a safe and efficient final installation. Can I do electrical rough-in by myself? Yes, with the .

“Rough-in” wiring means that all the electrical cables have been pulled through the studs of the wall and that boxes for light switches, outlets, and receptacles have been placed. But the wiring has not been connected to your . Even if you've never picked up an electrical tool in your life, you can safely rough-in wiring by following the directions in this article. You'll learn all of the pro techniques for a wiring job, including choosing the right size receptacle boxes, running cable throughout the room, and making the electrical connections. Installing rough electricity involves running electrical wiring, installing outlet boxes, and setting up light fixtures before the walls are closed. It’s really a job for a licensed electrician. In this video and guide, This Old House electrician Scott Caron discusses the key steps for installing rough electricity in a newly framed basement room.Part of an electrician’s job is setting boxes so they’ll be flush to finished surfaces. Before an electrician starts working, modifications to the framing—such as furring out or planing down irregular studs and ceiling joists—must be complete.

roughing in electrical outlets

Wire Strippers https://amzn.to/3e6jq2UIn this video I will show you how to install rough in electricity in a new construction house. This is how to do wire a. Standard electrical rough-in materials include various sizes of electrical wires to carry different loads, electrical boxes to house outlets and light switches, conduit to protect wiring, and staples to secure wires within wall and ceiling cavities. Metal fatigue can result in scored or broken conductors, which in turn can cause short circuits, heat buildup, and in the worst cases, fire. Installing a safe electrical system is a huge responsibility that guides our work at rough-in and at every stage of wiring a house.

To clarify, roughing in as an electrician refers to pulling wring, drilling holes, mounting box heights for receptacles and light switches, or bending emt pipe, building pipe racks, building an electrical room, or even looking at electrical prints and understanding panel and equipment schedules.Most of the materials installed during the rough-in phase can be installed either in new construction or remodel wiring. All materials must be UL- or NRTL-listed, which indicates that they meet the safety standards of the electrical industry. Knowing how to rough in electrical wiring ensures that the foundational electrical work is done correctly, paving the way for a safe and efficient final installation. Can I do electrical rough-in by myself? Yes, with the right tools and knowledge, you can undertake a .

dc junction box manufacturers

de perini metal fabricators inc dan

rough in electrical wiring layout

rough in electrical wiring diagram

$59.99

electrical box rough in|roughing in electrical outlets