stainless steel enclosure thermal conductivity Comparing international stainless steel standards from America (US), France, Germany, Italy, Japan, Russia, Spain, Sweden, England (UK) and the European Union. . If you are a new or beginner welder, watch this video to learn about the three most common welding processes — MIG, stick and TIG — including the advantages .

0 · thermal conductivity chart

1 · thermal conductivity

2 · stainless steel thermal properties

3 · stainless steel thermal conductivity

4 · stainless steel temperature range

5 · stainless steel temperature and conductivity

6 · stainless steel heat conductivity chart

7 · 304 stainless steel thermal conductivity

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

This article summarizes the thermal conductivity of stainless steel 304 and 316 at various temperatures in annealed condition, also other stainless steel grades. Stainless steel’s thermal conductivity varies with temperature rise. Typically, higher temps boost conductivity. For 304 stainless, it’s around 16.2 W/m Comparing international stainless steel standards from America (US), France, Germany, Italy, Japan, Russia, Spain, Sweden, England (UK) and the European Union. . If your application requires thermal conductivity, aluminum is the best choice because it can dissipate heat better than stainless steel. WELDING. . Explore our custom enclosures now, or contact us online to talk about your aluminum or stainless steel enclosure project. Share: Share on facebook. Share on twitter. Share on linkedin. Share on .

Which of the following discontinuities may result from a low coefficient of thermal conductivity combined with a high coefficient of thermal expansion? Meaning, the heat is localized and local expansion is more severe than steel? Cracking Carbide precipitation Distortion Oxidation The lower conductivity of stainless steel can also be an advantage in certain scenarios, such as in double-walled containers or thermal barriers, where insulating properties are desired. . such as grounding rods and electrical enclosures. In thermal systems, stainless steel’s strength and heat resistance make it suitable for industrial . Specific heat and thermal conductivity of stainless steel vs. temperature; Temperature Introduction to temperature - including Celsius, Fahrenheit, Kelvin and Rankine definitions - and an online temperature converter. Thermal Conductivity - Online Converter Convert between thermal conductivity units. Thermal Conductivity Unit Converter New measurements of the thermal conductivity of stainless steel AISI 304L over the temperature range 300 to 550 K are reported. To perform the measurements, the transient hot-wire technique was .

Inside the temperature controlled aluminum envelope was the 12.7mm thick stainless steel vac-uum chamber. For the purpose of reducing temperature gradients, an aluminum (15 times higher thermal conductivity than stainless steel) vacuum chamber would have been preferable, but a stain-less steel chamber is what we currently have. For instance, Type 304 stainless steel has a thermal conductivity of about 16.2 W/mLarge selection of stainless steel enclosures from Hubbell-Wiegmann available at excellent prices and in stock now at Automation24! . RTD probes Continuous level sensors Point level sensors Float level sensors Conductivity sensors Process adapters Mounting accessories . Electromagnetic flow meters Ultrasonic flow meters Thermal dispersion . And these highly filled thermoplastics, the best of which offer a thermal conductivity that tops out at about 100 W/mK, still don't beat the 80-160 W/mK offered by diecast aluminum. . Just to be sure, IMS and Cool Polymers engineers went on to machine enclosure prototypes out of stainless steel, which has roughly the same thermal conductivity .

Heat transfer through a surface like a wall can be calculated as. q = U A dT (1) where. q = heat transfer (W (J/s), Btu/h) U = overall heat transfer coefficient (W/(m 2 K), Btu/(ft 2 h o F)). A = wall area (m 2, ft 2). dT = (t 1 - t 2) = temperature difference over wall (o C, o F)The overall heat transfer coefficient for a multi-layered wall, pipe or heat exchanger - with fluid flow . The thermal conductivity of stainless steel can vary depending on the specific grade, but it typically ranges from 14 to 19 W/m- Unify enclosure material to stainless steel grade 304. - Add double meterbox details and drawings. 4 20-11-2023 2.1 . It shall be non-flammable with thermal conductivity of 0.0189 W/m.K. 5.2.6 M6 stainless steel threaded studs shall be fully welded on the hinges to

thermal conductivity of 304 stainless steel was 14,34 W/m.K =using parameter estimation techniques [7]. With reference value of 304 stainless steel was 14,9-16,2 W/m.K and the value of the thermal conductivity of brass is 150 W/m.K [8] or in the range of 109−160 / . [9]. 1.2.

thermal conductivity chart

Stainless steel is ideal for applications that are exposed to washdown cleaning processes, such as food and beverage processing. Type 304 stainless steel enclosures are used in both indoor and outdoor applications. Type 316 stainless steel contains molybdenum, which enables it to provide better overall corrosion resistant properties than Type .STAINLESS STEEL Stainless steel’s ability to resist corrosion comes from its chemical composition. Type 304 stainless steel (18-8) was named to reflect its 18% chromium and 8% nickel composition. Type 316 stainless steel, a higher grade version, has a 10% nickel, 16% chromium and 2% molybdenum content. Nickel and molybdenum provide increasedStainlessSteelElectricalConductivity. Calculates the electrical conductivity as a function of temperature for AISI 304 stainless steel in base SI units

2. Thermal Conductivity and Melting Points. Titanium is generally preferred over stainless steel in projects that require thermal stability at high temperatures. It conducts heat better and melts at 1,668°C in its pure form, in .However, integrating stainless-steel enclosures into process cooling systems requires consideration of their higher costs, increased weight, and thermal conductivity compared to alternatives like painted steel or aluminium. The initial investment for stainless-steel might be higher, reflecting its superior quality and benefits. Thermal conductivity (often expressed as k, λ, or κ) refers to the intrinsic ability of a material to transfer or conduct heat. It is one of the three methods of heat transfer, the other two being: convection and radiation. . About a month and a half after installing a pool ladder made of stainless steel, the area where the welds are .Thermal conductivity and thermal expansion ... 18 Data for engineering materials This booklet lists the names and typical applications common engineering materials, together with data . Stainless steel 7,600 - 8,100 5.9 - 6.5 Non-ferrous Aluminum alloys 2,500 - 2,900 2.1 - 2.3 Copper alloys 8,900 7.1 - 7.8 Lead alloys 10,000 – 11,000 6.9 .

by millisecond pulse-heating in comparison to thermal conductivity of the stainless steel AISI 316L . at elevated temperature High-Temp. High-Press. 46, 353–365 (2017) 24. H.W You then place a stainless steel sphere (ε SS = 0.45) of the same dimensions into the enclosure and find that it has the same radiated power as the aluminum sphere. What is the temperature (in K) of the stainless steel sphere? x The radiation equation gives radiated power as a function of temperature. . The thermal conductivity of the . To enhance the thermal conductivity of steel, a stainless steel-copper metal composite with up to 60 vol % of Cu was developed by premixing (light milling) the SS and Cu powder, followed by the LPBF process. Many LPBF process parameters were examined to achieve high relative density and minimal defect specimens. An investigation of the effect . The more basic models of stainless-steel cookware generally have poor heat transfer and distribution which makes cooking temperature sensitive dishes very challenging. This is due to stainless steel having one of the lowest thermal conductivities of .

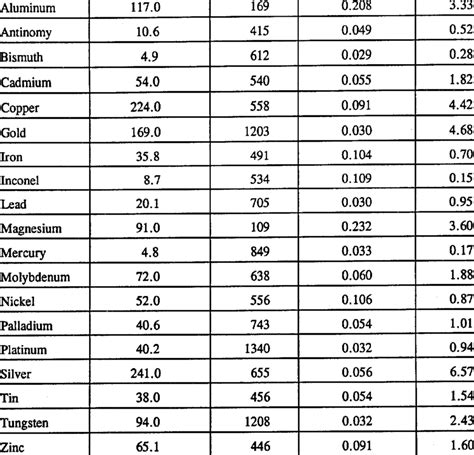

Thermal Conductivity Comparison: Stainless Steel 304 vs. Copper, Aluminum, and Other Metals. Stainless steel 304, with a thermal conductivity of approximately 16 W/m Thermal bridging can be defined as localized areas with a higher thermal conductivity than adjacent areas. A typical thermal bridge in a building enclosure occurs where a material of high conductivity, usually a structural component, penetrates the insulation layer. . consisting of stainless steel welded to carbon steel reinforcing bars .

thermal conductivity

stainless steel thermal properties

stainless steel thermal conductivity

“For comparison, a welding process might have overhead costs for labor, consumables, supplies, and equipment of $25 to $35 an hour. But the new laser cutting and machining equipment overhead rates per output hour could be three to four times that amount, and you’ll need to apply this to each associated labor hour, which is a significant .

stainless steel enclosure thermal conductivity|thermal conductivity chart