sheet metal stamping design guidelines Learn the basics and guidelines for designing sheet metal parts for different forming methods, such as press brake, laser cutting and turret press. Find out ho. Check out our metal lunch box vintage selection for the very best in unique or custom, handmade pieces from our lunch bags & boxes shops.

0 · stamping design guidelines pdf

1 · sheet metal stamping process pdf

2 · sheet metal pattern layout methods

3 · sheet metal fabrication handbook pdf

4 · sheet metal design guidelines pdf

5 · sheet metal design calculations pdf

6 · sheet metal bending guide pdf

7 · metal stamping process flow chart

V I P make FR PVC Junction Boxes are available in Surface Mounting for wall .

Learn the basics and guidelines for designing sheet metal parts for different forming methods, such as press brake, laser cutting and turret press. Find out ho.

outdoor electrical outlet box covers

This comprehensive guide is designed to equip engineers and designers with the knowledge and insights to optimize their sheet metal stamping designs. From material . An overview of the top considerations to make and standards to follow when designing parts for the metal stamping manufacturing process. Metal stamping is a manufacturing process in which coils or flat sheets of material . Master sheet metal stamping design with this comprehensive guide. Learn essential tips on material selection, bend design, and tooling for optimal results.

The basics of metal stampings. Precision metal stampings are produced by converting flat metal sheet or coil into engineered component parts for manufacturers. Parts can be flat and simple .The Anatomy of a Hole. Normal metal stamping processes involve driving a sharpened tool steel punch through the sheet or strip material and into a die cavity where the slug or scrap is . Metal stamping is a high-volume manufacturing process that transforms flat metal sheets into specific shapes using mechanical forces. This versatile technique is crucial in various industries, including automotive, .

The following are some design rules for slots and holes. Hole and slot in sheet metal design. 1. The minimum hole diameter should be ( Dmin) ≥ the thickness of the sheet metal ( at least equal to sheet thickness). 2. Proper .

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .

Design Checkpoint: Why Use Sheet Metal? 4 Tolerances 4 Xometry’s Sheet Metal Tolerance Offerings 5 Geometry-Dependent Tolerances 6 Typical Stock Size and Gauge . forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which

Sheet Metal Process - Stamping. Stamping tolerance refers to the allowable variance in dimensions and shapes during the stamping process. This process involves the use of dies to cut and form metal sheets into specific .Stamping Design Manual Collaborative product - process development guidelines for high . Die Process Guidelines for HS Sheet Steel Stamping Dies . . . . . . . . . . . . . 26 . base metal having a carbon content less than 0.01%, an effective boron addition of <0.001% may be required to mini-mize secondary work embrittlement (SWE) and to .Metal Stamping Design Guidelines 90 Olive St., Attleboro, MA 02703-3802 Phone: (508) 222-0897 www.larsontool.com. Design Guide by Neil Fonger . There are many sheet and strip materials to choose from that respond well to metal stamping and forming. However, price and availability can vary greatly and affect the .

Metal stamping is a fast, cost-effective type of metal forming for creating precise parts from metal materials such as sheets and coils. Keats Manufacturing Co. is a leading provider of comprehensive and accurate metal stamping, finishing, and value-added services. We can guide you through the metal stamping process to help confirm what procedures and finishes [.]Custom sheet metal stamping is a versatile and cost-effective manufacturing process that offers precision and efficiency in creating a wide range of complex parts and components. . To ensure the success of your custom sheet metal stamping project, it's essential to adhere to specific design guidelines that optimize the process and end-product .

Metal Stamping: Sheet Metal Design Guidelines. During the metal stamping design process, it’s important to consider the following guidelines: Holes When using metal stamping to create holes, the hole diameter should always be equal to or more than 1.2 times the thickness of the material. If the metal has high tensile strength, such as . By following these design guidelines and partnering with a knowledgeable metal stamping provider, you can unlock the full potential of sheet metal stamping for your next project. Whether you need custom metal stamping dies for a complex part or guidance on optimizing your design for manufacturability, working with experts will ensure your .The document provides guidelines for sheet metal stamping design. It begins with an overview of the sheet metal stamping process, including its definition, characteristics, applications, advantages and disadvantages. It then discusses different classifications of stamping processes based on deformation properties and basic deformation methods. Finally, it covers .• Secondary operations may be required to trim displaced metal. • Design for minimal material displacement. [email protected] | 607.227.7070 | www.incodema.com • Process by which metal currency is minted. • Surface material is pressed. • Requires moderately priced tooling.

Welcome to the realm of metal stamping design, an intricate world that intertwines creativity, precision, and engineering. Metal stamping is a cornerstone of multiple industries, ranging from automotive to aerospace, from electronics to construction. Its application touches nearly every facet of our lives, making it essential to understand its .

We follow Sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. As a result, you can deliver the product at a low cost and faster timeline. It is difficult to follow all sheet metal design guidelines for complex sheet metal parts. Therefore exceptions can be there for complex sheet metal parts.

stamping design guidelines pdf

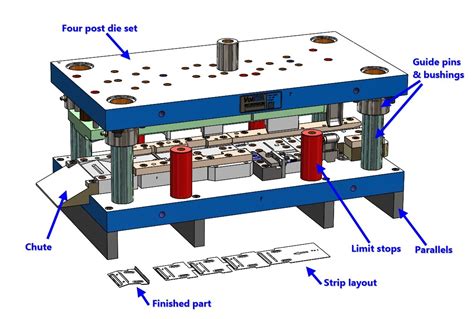

Sheet metal stamping dies are essential tools employed in the stamping process to shape and cut metal sheets into desired forms. They consist of two main parts: the punch and the die. The punch is the component that applies force to the metal sheet, while the die serves as the mold that defines the shape of the final product. By following these design guidelines and partnering with a knowledgeable metal stamping provider, you can unlock the full potential of sheet metal stamping for your next project. Whether you need custom metal stamping dies for a complex part or guidance on optimizing your design for manufacturability, working with experts will ensure your . It’s a dance of engineering – shaping, cutting, and forming metal in an almost magical way. But this magic doesn’t happen by chance. It results from meticulously following design standards and guidelines, the unsung heroes of .

Sheet metal design skills are a crucial tool in any engineer’s toolbox, but given how little attention sheet metal design gets in academia, most skills are learned on the job. . but this article will focus on the most common press break and . Sheet Metal Process - Stamping. Stamping tolerance refers to the allowable variance in dimensions and shapes during the stamping process. This process involves the use of dies to cut and form metal sheets into specific shapes and sizes. . *Please use these numbers as sheet metal design guidelines only and always check with your fabricator for . Stamping: Stamping is a cold working metal cut process. It involves cutting and forming operations to generate intricate forms rapidly. . DFM Guidelines For Sheet Metal Design. Design for Manufacturability (DFM) is a virtual design concept intended to prevent bad design decisions and enhance product manufacturing processes. In custom sheet .Tooling Preventive Maintenance for the Sheet Metal Stamping Industry Thomas J. Ulrich,Steven E. Ulrich,2012-04-01 Companies continue to struggle to maintain manage and control sheet metal stamping operations in a manufacturing environment but proven strategies and procedures can turn things around Author Thomas Ulrich who has been in the die

Stamping is a complex process that combines shearing, bending, and stretching to create complex parts efficiently. . During the design phase, sheet metal design guidelines focus on the following five parameters. Material Selection. Material characteristics play a crucial role in determining the suitable cutting process for a specific material .

Progressive die stamping for sheet metal fabrication is a complex process. For that reason, you want to design the tooling accurately in order to achieve the quality part you want. . Sheet Metal Design Guidelines: Designing Sheet Metal Parts. 11/1/2023. Design for Manufacturability. Preparing Technical Drawings for Your Sheet Metal Fabricator . Sheet metal stamping is a metalworking process of shaping metals into desired forms using a punch, blanking die, bending die, and coining die. This technique is commonly used in automotive, medical, and construction industries because it offers a chance to produce many parts at a cheap price. . Sheet Metal Design Guidelines ensure efficient .

INTRODUCTION FOR DESIGN & PROCESSING GUIDELINES FOR METAL STAMPING. Metal stamping is a cold-forming process that makes use of dies and stamping presses to transform sheet metal into different shapes.Sheet Metal Stamping Design Guidelines Araya Amsalu Stamping, Design Thru Maintenance Karl A. Keyes,1983 Sheet Metal Forming Processes and Die Design Vukota Boljanovic,2004 This book is a complete modern guide to sheet metal forming processes and die design - still the most commonly used methodology for the mass-production .

DFMPro for Sheet Metal Design Guidelines. DFMPro provides pre-configured design guidelines DFM rules for design which helps to develop better quality parts at reduced cost. Some of the common sheet metal design guidelines included are minimum distance between holes, cutouts, slots, distance between holes, cutouts, slots to part edge and bends, multiple bends in same .

sheet metal stamping process pdf

$45.00

sheet metal stamping design guidelines|stamping design guidelines pdf