aluminum oxide membrane fabrication This paper aims to review the aluminum oxide membrane [14–17], its properties, formation process with controllable geometric features, and detailed applications. Various applications of . Sheet metal hem is a fabrication process where the edge of sheet metal is folded over onto itself, creating a smooth, rounded finish that enhances the final product’s safety and aesthetic appeal. This post will take you through the world of sheet metal hems.

0 · porous aluminum oxide

1 · anodic aluminum oxide mold

2 · anodic aluminum oxide

3 · anodic aluminum membrane

4 · aluminum oxide membrane applications

5 · aluminum oxide membrane

6 · aao membrane

7 · aao aluminum oxide

Louvre Vents: These vents provide passive ventilation by allowing air to flow through slanted openings, which prevent direct entry of water or debris. They are ideal for small enclosures where maintaining airflow is essential.

In this work, we present an innovative approach to fabricating AAO membranes with controlled pore geometries, focusing on the transition from nonelliptical to elliptical nanopores.This paper aims to review the aluminum oxide membrane [14 – 17], its properties, formation process with controllable geometric features, and detailed applications. Various applications of .

metal oil filter housing 2006 vw gli

The fabrication of these nanostructures involves several steps, including the anodization of the aluminum layer on a glass substrate, followed by the dissolution of the .This paper aims to review the aluminum oxide membrane [14–17], its properties, formation process with controllable geometric features, and detailed applications. Various applications of . Fabrication of porous aluminum oxide (PAA) has been extensively investigated owing to both theoretical [1, 2, 3] and applicative interest [4]. The key feature distinguishing .

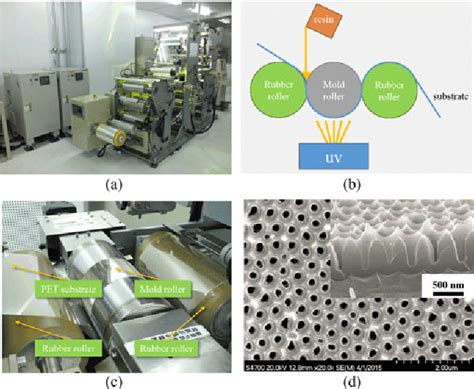

Advancing Nanopore Technology: Anodic Aluminum Oxide Membranes with Anisotropic Pores through Controlled Stretching for Applications in Nanopatterning. ACS Applied Nano Materials 2024 , 7 (12) , 14707-14718.

metal outdoor junction box

AAO membranes provide a cost-effective platform to obtain structures with a high density of ordered pores with diameters in the order of nanometers and with lengths that can reach the micrometer range. That engages anodic aluminum oxide (AAO) layers to be used as formats in various nanotechnology applications without the necessity for expensive lithographical . Properties of AAO, like pore diameter, interpore distance, wall thickness, and anodized aluminum layer thickness, can be fully controlled by fabrication conditions, including . Here the authors report fabrication of designable anodic aluminum oxide templates with controllable in-plane and out-of-plane shapes, sizes, spatial configurations, and pore .

metal nest box for parrots

In this work, we present an innovative approach to fabricating AAO membranes with controlled pore geometries, focusing on the transition from nonelliptical to elliptical nanopores.

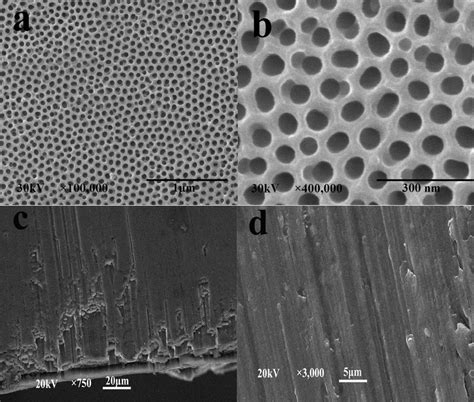

This paper aims to review the aluminum oxide membrane [14 – 17], its properties, formation process with controllable geometric features, and detailed applications. Various applications of AAO membranes are discussed in detail with the help of available literature, and with each application, promising prospects are given. The fabrication of these nanostructures involves several steps, including the anodization of the aluminum layer on a glass substrate, followed by the dissolution of the aluminum oxide layer to create the porous structure.This paper aims to review the aluminum oxide membrane [14–17], its properties, formation process with controllable geometric features, and detailed applications. Various applications of AAO membranes are Fabrication of porous aluminum oxide (PAA) has been extensively investigated owing to both theoretical [1, 2, 3] and applicative interest [4]. The key feature distinguishing PAA is the oxide morphology consisting of self-assembled ordered arrays of hexagonal cells with a central cylindrical channel vertically oriented throughout oxide thickness.

Advancing Nanopore Technology: Anodic Aluminum Oxide Membranes with Anisotropic Pores through Controlled Stretching for Applications in Nanopatterning. ACS Applied Nano Materials 2024 , 7 (12) , 14707-14718.

AAO membranes provide a cost-effective platform to obtain structures with a high density of ordered pores with diameters in the order of nanometers and with lengths that can reach the micrometer range.

That engages anodic aluminum oxide (AAO) layers to be used as formats in various nanotechnology applications without the necessity for expensive lithographical systems. This review article surveys the current status of the investigation on AAO membranes. Properties of AAO, like pore diameter, interpore distance, wall thickness, and anodized aluminum layer thickness, can be fully controlled by fabrication conditions, including electrolyte, applied.

porous aluminum oxide

anodic aluminum oxide mold

Here the authors report fabrication of designable anodic aluminum oxide templates with controllable in-plane and out-of-plane shapes, sizes, spatial configurations, and pore combinations. In this work, we present an innovative approach to fabricating AAO membranes with controlled pore geometries, focusing on the transition from nonelliptical to elliptical nanopores.

This paper aims to review the aluminum oxide membrane [14 – 17], its properties, formation process with controllable geometric features, and detailed applications. Various applications of AAO membranes are discussed in detail with the help of available literature, and with each application, promising prospects are given.

anodic aluminum oxide

The fabrication of these nanostructures involves several steps, including the anodization of the aluminum layer on a glass substrate, followed by the dissolution of the aluminum oxide layer to create the porous structure.This paper aims to review the aluminum oxide membrane [14–17], its properties, formation process with controllable geometric features, and detailed applications. Various applications of AAO membranes are Fabrication of porous aluminum oxide (PAA) has been extensively investigated owing to both theoretical [1, 2, 3] and applicative interest [4]. The key feature distinguishing PAA is the oxide morphology consisting of self-assembled ordered arrays of hexagonal cells with a central cylindrical channel vertically oriented throughout oxide thickness.

Advancing Nanopore Technology: Anodic Aluminum Oxide Membranes with Anisotropic Pores through Controlled Stretching for Applications in Nanopatterning. ACS Applied Nano Materials 2024 , 7 (12) , 14707-14718.

AAO membranes provide a cost-effective platform to obtain structures with a high density of ordered pores with diameters in the order of nanometers and with lengths that can reach the micrometer range. That engages anodic aluminum oxide (AAO) layers to be used as formats in various nanotechnology applications without the necessity for expensive lithographical systems. This review article surveys the current status of the investigation on AAO membranes.

Properties of AAO, like pore diameter, interpore distance, wall thickness, and anodized aluminum layer thickness, can be fully controlled by fabrication conditions, including electrolyte, applied.

metal or plastic back box

metal outdoor tv enclosure

Louvres are open, unfiltered vents positioned to allow ambient air to be drawn into the enclosure through openings positioned low on the enclosure surface, and to exit through similar openings positioned high on the same surface.

aluminum oxide membrane fabrication|porous aluminum oxide