cnc turning plastics parts CNC plastic machining is a technique whereby plastic cutting tools are guided by computer numerical control technology. The process, also known as CNC, involves accurate movements of tools and workpieces and predetermined computer instructions that make different plastics including parts and products. A septic distribution box is required for proper drainage and management of waste in a septic system. Our concrete septic distribution boxes do the trick!

0 · turned parts manufacturer

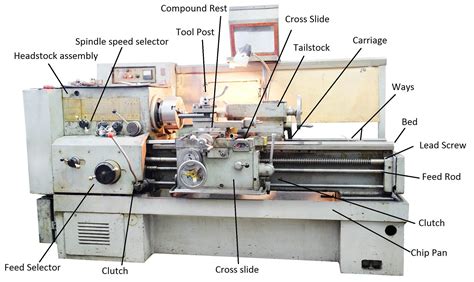

1 · parts of cnc lathe machine

2 · high precision milling metal parts

3 · cnc turning services near me

4 · cnc turning machining parts factory

5 · cnc turning machining parts

6 · cnc turned parts manufacturer

7 · cnc machined parts buyers

Sheet metal is one of the shapes and forms metal can be bought in. Sheet metal is any metal that has a thickness in between 0.5.6 millimetres. There are other measurement units used to categorise metals by thickness, though.

turned parts manufacturer

CNC plastic machining is a technique whereby plastic cutting tools are guided by computer numerical control technology. The process, also known as CNC, involves accurate movements of tools and workpieces and . Learn how to select the right plastic for CNC machining. Avoid pitfalls, ensure optimal performance, and reduce costs for your CNC machined parts with our comprehensive guide.

CNC plastic machining is a technique whereby plastic cutting tools are guided by computer numerical control technology. The process, also known as CNC, involves accurate movements of tools and workpieces and predetermined computer instructions that make different plastics including parts and products.

exterior electrical box covers

Learn how to select the right plastic for CNC machining. Avoid pitfalls, ensure optimal performance, and reduce costs for your CNC machined parts with our comprehensive guide. CNC plastic machining utilizes a subtractive process to gradually cut a plastic block to the desired shape and precision. Depending on the plastic material, design complexity, and precision requirements, 3, 4, or 5-axis CNC machines are typically used to machine the parts. Based on the CNC machining method — CNC drilling, CNC turning, or CNC milling — engineers must adhere to different guidelines to produce superior plastic CNC machined parts. In this article, we’ll break each of them down.Get precision CNC turned parts for prototyping and production with RALLY, delivering top-quality metal and plastic components as quickly as 2-3 day. Start with an instant online quote. At Rally, we understand that it is essential to meet the technical specifications of customers’ orders in an accurate and timely manner.

Plastic machining factories rely on computer-controlled devices to form raw materials into designated pieces. It is this technique, known for its accuracy, which works particularly well with plastics, giving one a cheaper option of .Parts & Products. For over 40 years EPP has been providing top US companies the critical custom machined plastic parts they need. EPP is able to provide parts machined to tight tolerances and the highest quality standards. We use state-of-the-art CNC milling and turning machines and are able to provide both short and long runs.

Plastic CNC machining is a subtractive manufacturing method that involves placing a solid block of plastic against a moving cutting tool that removes material from the block. In order to shape the final product, the cutting tool follows a predetermined path directed by a digital design file.CNC turning is a subtractive manufacturing process that involves using a CNC lathe to shape a workpiece by rotating it against stationary cutting tools. This precision-focused process can create highly complex cylindrical parts with tight tolerances.

With the ability to rotate and advance the workpiece, CNC turning machines can produce a wide range of parts with complex geometries. CNC turning also offers the flexibility to work with various materials, including metals, plastics, and composites. CNC plastic machining is a technique whereby plastic cutting tools are guided by computer numerical control technology. The process, also known as CNC, involves accurate movements of tools and workpieces and predetermined computer instructions that make different plastics including parts and products. Learn how to select the right plastic for CNC machining. Avoid pitfalls, ensure optimal performance, and reduce costs for your CNC machined parts with our comprehensive guide. CNC plastic machining utilizes a subtractive process to gradually cut a plastic block to the desired shape and precision. Depending on the plastic material, design complexity, and precision requirements, 3, 4, or 5-axis CNC machines are typically used to machine the parts.

Based on the CNC machining method — CNC drilling, CNC turning, or CNC milling — engineers must adhere to different guidelines to produce superior plastic CNC machined parts. In this article, we’ll break each of them down.Get precision CNC turned parts for prototyping and production with RALLY, delivering top-quality metal and plastic components as quickly as 2-3 day. Start with an instant online quote. At Rally, we understand that it is essential to meet the technical specifications of customers’ orders in an accurate and timely manner.

Plastic machining factories rely on computer-controlled devices to form raw materials into designated pieces. It is this technique, known for its accuracy, which works particularly well with plastics, giving one a cheaper option of .

Parts & Products. For over 40 years EPP has been providing top US companies the critical custom machined plastic parts they need. EPP is able to provide parts machined to tight tolerances and the highest quality standards. We use state-of-the-art CNC milling and turning machines and are able to provide both short and long runs.

Plastic CNC machining is a subtractive manufacturing method that involves placing a solid block of plastic against a moving cutting tool that removes material from the block. In order to shape the final product, the cutting tool follows a predetermined path directed by a digital design file.CNC turning is a subtractive manufacturing process that involves using a CNC lathe to shape a workpiece by rotating it against stationary cutting tools. This precision-focused process can create highly complex cylindrical parts with tight tolerances.

extended pin box weight distribution

Since the largest size raceway for the top/bottom (vertical) dimension is a 2-inch conduit, the minimum height of the box is 16 inches (see Figure 3). The minimum size box required for the example in Figure 3 is 24 by 16 inches. What if, upon .

cnc turning plastics parts|cnc turning services near me