what is cnc in additive manufacturing The reality is much different. Just like CNC machining, says Conrow, additive manufacturing is a powerful, sophisticated manufacturing resource that has to be understood on its own terms. His business, C&A Tool .

Outdoor Electrical Box Waterproof 11.5*7.4*5.5*in, IP65 ABS Outdoor Power Strip Weatherproof, Protect Outlet, Extension Cord, Power Strip, Timers, Junction, for Outdoor Power Tools, Lamp Decorations 4.6 out of 5 stars

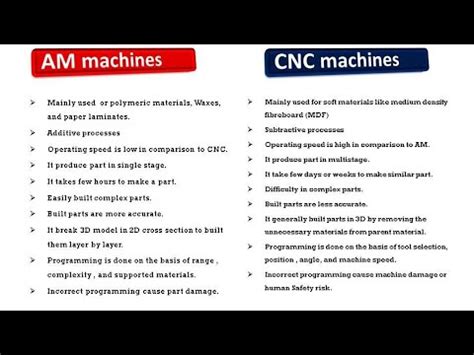

0 · difference between cnc and am

1 · difference between cnc and additive manufacturing

2 · cnc machining vs am

Sigma's weatherproof two-gang boxes provide a junction for conduits and can house up to two wired devices such as a receptacle or switch. The rugged, die-cast construction prevents .

The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while .Additive manufacturing is more resource-friendly as it uses less material compared to CNC machining. In AM, material is only added where it's needed, reducing waste. CNC machining .

Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is .Understanding Additive Manufacturing and CNC Machining. Cutting through the jargon, the essence of Additive Manufacturing (AM) and Computer Numerical Control (CNC) Machining rests on three core principles: design, production, . Unlike additive manufacturing, CNC machining is a subtractive manufacturing method that starts with a block of raw material and removes it bit by bit using rotating tools until it achieves the desired shape. The reality is much different. Just like CNC machining, says Conrow, additive manufacturing is a powerful, sophisticated manufacturing resource that has to be understood on its own terms. His business, C&A Tool .

difference between cnc and am

In the realm of modern manufacturing, CNC Subtractive Manufacturing (CSM) stands as the bedrock of precision, versatility, and top-notch surface quality. Conversely, Additive Manufacturing (AM) represents an exciting frontier for .Additive manufacturing and CNC manufacturing are two popular production techniques that produce precise and functional metal parts fast and efficiently. Both are powerful and sophisticated manufacturing resources that bring any . Boeing and other manufacturers use three primary criteria to measure the value of additive manufacturing (AM) against CNC Machining: part performance, cost and lead time .

city diagram electric box green pipes wires engineer underground

This article explores the differences between additive manufacturing and CNC machining, two different manufacturing processes used to create objects. While both processes have their strengths and weaknesses, .Additive Manufacturing. Additive manufacturing, commonly known as 3D printing, is a process where objects are built layer by layer from digital models. Unlike subtractive manufacturing, which removes material, additive manufacturing .Before choosing whether to use additive manufacturing or CNC machining, several aspects need to be considered: 1. Design complexity and geometry: If your design involves complex internal structures or intricate shapes, additive manufacturing might be more suitable. 2. Material requirements: Consider the availability of the desired material for . Introduction to Additive Manufacturing (AM) Additive Manufacturing (AM), also known as 3D printing, is a transformative process that converts digital designs into physical objects by layering materials sequentially. This innovative technology can significantly reshape traditional manufacturing methods and has already shown remarkable applications in .

difference between cnc and additive manufacturing

Additive manufacturing versus conventional manufacturing. Despite all the advantages of additive manufacturing, “I don’t see traditional manufacturing being replaced,” said Roemer. That is because, aside from specific use cases, traditional manufacturing is still faster and less expensive. This is especially true when creating granular . Additive manufacturing technology or 3D printing is a type of technology that uses successive layers of material to create 3D objects. . The surface quality of AM parts generally falls short of that achieved by conventional processes such as CNC machining and investment casting, often requiring additional finishing work.Additive Manufacturing (AM) แปลตรงตัวเลย การผลิตแบบเติมเข้าไป บางครั้งอาจจะใช้คำว่า 3D Printing, Rapid Prototype ล้วนมีความหมายเดียวกัน เป็น CAM(Computer Aided Manufacturing .

What does “additive manufacturing” mean? Additive manufacturing refers to a fabrication process where the material is added, rather than removed, to create an object. For instance, an artist constructing an object by welding pieces of metal together is using an additive process. An assembly line where plastics are poured into molds is using . Additive manufacturing (AM) has evolved significantly over the decades, becoming revolutionary. Here is a brief overview of its key milestones: The 1950s-1980s: The Birth of Additive Manufacturing. 1950s: The concept of layer-by-layer manufacturing was first explored with numerical control (NC) systems.

In today's world of manufacturing technology, you don't have to look further than additive manufacturing (AM) and CNC manufacturing (CNC) to find two examples of manufacturing's growth in technology. These technologies have become indispensable tools in modern industry and manufacturing. CNC vs 3D printing: Additive vs subtractive manufacturing. Unlike 3D printing, CNC is subtractive rather than additive. The CNC process starts with a larger block of material as the workpiece, and removes areas, like chipping away at marble – to get to the final model. 3D printers instead use additive manufacturing technologies.

Study with Quizlet and memorize flashcards containing terms like Additive Manufacturing is known by many names; which one of the following is not known as an AM process? A. Rapid Prototyping B. 3D Printing C. Photolithography, Which form of the following additive manufacturing method has the longest history? A. Subtractive B. Fabricative C. Formative D. Additive, .

Manufacturing Solutions for FANUC CNC Meltio takes Additive Manufacturing to the next level by delivering high-performance, affordable, and easy-to-use metal Additive Manufacturing solutions using wire LMD technology; the safest, cleanest, and most affordable metal feedstock on the market. CNC Engineering & Meltio have designed a solution that .

Additive manufacturing (AM) or additive layer manufacturing (ALM) is the industrial production name for 3D printing, a computer controlled process that creates three dimensional objects by depositing materials, usually in layers.. Contents. Click the links below to .

Using CNC Machining to Create Precise 3D Printed Parts. Looking at the chart above, you will notice that one of the key differences between additive manufacturing and subtractive manufacturing is the surface finish and .Ultrasonic additive manufacturing (UAM) works by using vibrations to weld successive layers of metal foil together, gradually building up a solid metal part. UAM systems integrate room temperature ultrasonic welding of foil with CNC . However, it is the most expensive additive manufacturing method, though it creates parts with good mechanical properties. Sheet Lamination. Like all additive manufacturing processes, sheet lamination builds parts in layers. .Additive manufacturing (often referred to as rapid prototyping or 3D printing) is a method of manufacturing where layers of material are built up one at a time to create a solid object. While there are many different additive manufacturing and 3D printing technologies out there, this article will focus on the general process from design to the .

clamps for outside junction box

CNC and additive manufacturing each offer unique benefits suited to different applications. CNC machining is known for its precision and ability to produce high-quality finishes. This makes it ideal for industries like aerospace, automotive, and medical device manufacturing, where parts must meet stringent specifications. . CNC machining is a computer-controlled manufacturing process that uses pre-programmed software to dictate the movement of factory tools and machinery. This technology enables the creation of complex three-dimensional cutting tasks with a single set of prompts, offering unparalleled precision and reproducibility.

What’s Additive manufacturing? Additive manufacturing, commonly known as 3D printing, is an industrial computer-controlled process that produces 3D objects by depositing materials in layers on the base material. The main core of this method is the addition of material together to create a new object.

Ultrasonic additive manufacturing (UAM), also known as ultrasonic consolidation (UC), is a hybrid sheet lamination process that brings together ultrasonic welding and computer numerically controlled (CNC) milling. . with the CNC mill operating as the additive build continues. UAM was invented and patented by Dawn White in 1999, who went on to . Another key difference between CNC and additive manufacturing is the speed. When it comes to mass-producing a product, CNC machining is faster because it involves an assembly line of machines producing each part. A single 3D printer makes the entire product from start to finish, which makes it less suitable for large-scale production. .Additive manufacturing is a process that builds parts and products by adding material rather than by taking away from it as in CNC machining. One of the most common forms of additive manufacturing is 3D printing. Additive manufacturing utilizes .

cnc machining vs am

The free to access Metal Additive Manufacturing magazine archive offers unparalleled insight into the world of metal Additive Manufacturing from a commercial and technological perspective through:. Reports on visits to leading metal AM part manufacturers and industry suppliers; Articles on technology and application trendsThis is as opposed to a traditional manufacturing process, like CNC Machining, where a part is built by subtracting material from a block of material. 3D printing and additive manufacturing can be used regardless if the parts are fabricated in plastic, metal, or rubber.

Ultrasonic Additive Manufacturing (UAM), also known as Ultrasonic Consolidation (UC), is an additive manufacturing (AM) or 3D metal printing technology. UAM belongs to the ‘sheet lamination’ family of AM processes, along with Laminated Object Manufacturing (LOM).

clair electrical box puzzle

clamshell hinged metal boxes

WEATHERPROOF PROTECTION: Provides robust protection for in-use plugs and outlet boxes, significantly increasing your electrical safety while enjoying your outdoor activities. COMPLETE KIT: Includes Metal Junction Box with (3) 1/2" Holes, (2) Closure Plugs, Tamper Resistant and Weather Resistant (TRWR) GFCI Receptacle, Plastic In-Use Cover with .

what is cnc in additive manufacturing|difference between cnc and additive manufacturing