forming corners sheet metal a. sheet metal sink which consists in preparing a sheet of metal for constructing the main or central portion of the sink, rolling the longitudinal edges into cylindrical-like shape, bending parallel port'ons of the sheet upwards to form respectively the front and. back of the sink with easilycleanable curves at the bends, preparing two sheets of metal shaped for the two ends of . $38.98

0 · sheet metal bending processes

1 · sheet metal bending design

2 · sheet metal bending angles

3 · how to bend sheet metal

4 · corner relief sheet metal

5 · corner construction sheet metal parts

6 · corner construction on sheet metal

7 · copper sheet metal bending

Discover current aluminum prices and market trends from Ryerson's metal experts. Get up-to-date insights on what is the price of aluminum and make informed decisions for your metal needs.

Corner construction plays a vital role in ensuring the durability and strength of sheet metal parts. When corners are not properly prepared for .

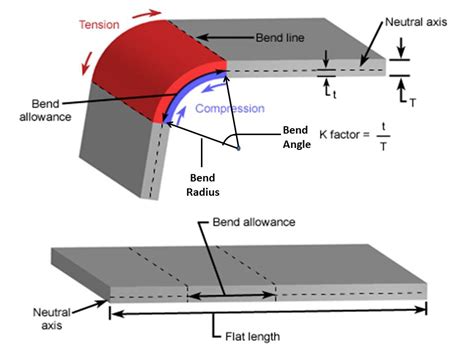

Bending is one of the most common sheet metal fabrication techniques. With bending, metal is deformed with specialist machinery into an angular shape. The bending of sheet metal allows . Sheet Metal Rounded Corners: Sheet metal forming refers to a broad set of manufacturing processes used to convert flat metal sheets into desired shapes and geometries. It is an essential part of the metalworking industry, widely used in the automotive, aerospace, construction, and electronics industries. .a. sheet metal sink which consists in preparing a sheet of metal for constructing the main or central portion of the sink, rolling the longitudinal edges into cylindrical-like shape, bending parallel port'ons of the sheet upwards to form respectively the front and. back of the sink with easilycleanable curves at the bends, preparing two sheets of metal shaped for the two ends of .

Get top-notch Metal Forming services with advanced metal forming technology in Seven Corners, VA. Choose our metal forming experts for all your metal forming needs. Call for Exceptional Performance (360) 636-5990. Home; About; . Performance Sheet Metal Proudly Serves The USA From The Great State of Washington. Virginia (360) 636-5990; Send Us .Get top-notch Metal Forming services with advanced metal forming technology in Four Corners, OR. Choose our metal forming experts for all your metal forming needs. Call for Exceptional Performance (360) 636-5990. Home; About; . Performance Sheet Metal Proudly Serves The USA From The Great State of Washington. Oregon (360) 636-5990; Send Us .Using Forming Tools with Sheet Metal: Sheet Metal Parts: Multibody Sheet Metal Parts: Using Sheet Metal Bend Parameters: Simulation: Sketching: . To add weld beads to a sheet metal corner: Click Welded Corner (Sheet Metal toolbar) or Insert > Sheet Metal > Welded Corner. Select one of the corner faces. Set options in the PropertyManager .Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. . Recommended corner radius for notches should be 0.5 * t. Notches must be at least the material’s thickness or 0.04”, whichever is greater, and can be no longer than 5 times its width. Tabs must be at least 2 times the .

Sheet metal forming can be applied to a variety of metals, including steel, aluminum, brass, and copper, allowing manufacturers to produce parts for a wide range of applications. Hydraulic Metal Forming Sheet Metal Rounded Corners. Hydraulic metal forming is a process where hydraulic pressure is used to shape metal workpieces. This process is .Sheet Metal Work Processes. Sheet metal forming is a manufacturing process that uses various techniques to shape thin metal sheets into desired parts. . This is a method that removes material from the edge or corner of sheet metal by making V-shaped or U-shaped cuts. It can be used to create slots, grooves, or angles in sheet metal for .Get top-notch Metal Forming services with advanced metal forming technology in Four Corners, MD. Choose our metal forming experts for all your metal forming needs. Call for Exceptional Performance (360) 636-5990. Home; About; Service; . Performance Sheet Metal provides custom metal forming services in Four Corners, MD to ensure optimal .

Sheet Metal Corner forming machine is used in the processing of sheet mental corner forming such as cold-rolled plate, aluminum plate, stainless steel plate, copper plate etc. Widely used in the switching door, cover plate, aluminum single panel curtain wall, switchboard, container cover, household appliances, instruments and other fields.Free . Generally, sheet metal refers to metal materials with uniform thickness. Common sheet metal materials include stainless steel, galvanized steel, tinplate, copper, aluminum, and iron. This article primarily analyzes the basic principles of sheet metal product design. Sheet metal forming can be applied to a variety of metals, including steel, aluminum, brass, and copper, allowing manufacturers to produce parts for a wide range of applications. Hydraulic Metal Forming Sheet Metal Rounded Corners. Hydraulic metal forming is a process where hydraulic pressure is used to shape metal workpieces. This process is . SolidWorks Sheet Metal Tutorial for Beginner - 2 | Closed Corner, Welded Corner, Break Corner, Corner Trim, Forming Tool. This tutorial shows how to create f.

Get top-notch Metal Forming services with advanced metal forming technology in Peachtree Corners, GA. Choose our metal forming experts for all your metal forming needs. Call for Exceptional Performance (360) 636-5990. Home; About; Service; Capabilities. . Performance Sheet Metal provides custom metal forming services in Peachtree Corners, GA .

Get top-notch Metal Forming services with advanced metal forming technology in Five Corners, WA. Choose our metal forming experts for all your metal forming needs. Call for Exceptional Performance (360) 636-5990. Home; About; Service; . Performance Sheet Metal provides custom metal forming services in Five Corners, WA to ensure optimal .Study with Quizlet and memorize flashcards containing terms like When creating a sheet metal____, create the profile in that shape from the start., Base Flange, Bend Allowance Options and more. . Corner-Trim tool. Cuts or adds material to flattened sheet metal parts on an edge or a face. Edge Flange.Critical Dimensions Sheet Metal Forming – Outside dimension should be used unless the inside dimension is critical. - 3 - . Corners - May be sharp, however to reduce tooling costs, specify radii of ½ material thickness or a minimum of .015”.

sheet metal bending processes

Fold corners in flat metal sheets to create your own bin boxes, drip pans, and other three-dimensional objects. . Also known as body and fender tools, these hammers are excellent for forming and repairing dents in sheet metal components. Delicate Metal Forming Hammers. Deep drawing and hydroforming are two different sheet metal forming processes. . Parts with sharp corners, deep draws, or complex features may require additional tooling or modifications to the hydroforming process. It’s also essential to consider the die design, including the shape and size of the die cavity, as well as the placement of .

Hydroforming is a metal forming process that can create complex and structurally strong parts from ductile metals. It is done by exerting a highly pressurized fluid force of up to 10,000 PSI onto a piece of metal to change its shape. . In the sheet metal hydroforming process, a metal blank is placed on the hydroform press. . Tight Corners .

Bending dies are critical components in sheet metal forming, directly influencing the final part’s geometry, accuracy, and surface quality. . To achieve higher accuracy, it is recommended to opt for a small bend radius while designing rounded corners of sheet metal bends. Avoid using large arcs as much as possible, as depicted in Figure 1 .The raw and flange corner joint is a type of sheet metal joint that closely resembles a plain lap joint and involves a flat stock piece joined to a 90-degree bend to form the corner. . Creating a flange joint involves forming a flange on each piece and then placing one on top of the other, with both types being formed in a similar fashion. .Metal Stamping: Sheet Metal Design Guidelines. During the metal stamping design process, it’s important to consider the following guidelines: Holes . When forming corners, it’s important to be as generous as possible to facilitate manufacturing. The radius of the punch and die should be at least four times the thickness of the material.

While the forming order isn’t an issue with a 100 percent weld notch, the forming order is an issue with the 50 percent weld notch. The relieved notch offers clearance in the corner, and it’s often designed into a part so that the corner itself can mate on the inside of another square corner—to a shelf, for example. The Mold Line Our guide offers a comprehensive list of 71 key terms and definitions to help you navigate the world of sheet metal fabrication with confidence. Close; Articles . The process of smoothing the sharp corners of a workpiece using a mold, file, grinding machine, etc. . This blog post delves into the intricate processes of sheet metal forming . Sheet Metal Part Design for Manufacturing Tip CORNERS AND WELDING. Proper technique on corners that need to be welded is necessary to reduce cost and increase the overall strength of the corners. Approved Sheet Metal will always reprogram corners that need to be welded to ensure customers receive the best possible welds.

The sheet metal passes between the rollers, and the pressure shapes the desired bead profile. . slightly, like on the edge of a pie crust. Stretching involves expanding it, like when you spread a pie crust into the corners of a pan. . This is often done with dies that shape and simultaneously punch holes in the metal, forming the desired .

sheet metal bending design

toyota tocama metal oil filter housing

tornos cnc argentina

sheet metal bending angles

Andea's custom sheet metal fabrication services are a cost-effective, on-demand solution to your manufacturing needs. Our fabrication services range from low-volume prototype to high-volume production runs. You can submit your 2D or 3D drawings to get instant quotes directly.

forming corners sheet metal|sheet metal bending design