solidworks 2016 sheet metal You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, . Consider using L-brackets to anchor the headboard to the bed frame if you don’t want to use screws, bolts or nails. You can attach them directly to both pieces of furniture for a secure and strong hold. If your headboard is made from a lightweight wood, try using two-way tape to attach the headboard to the bed frame.

0 · solidworks sheet metal pdf

1 · solidworks sheet metal examples

2 · solidworks sheet metal download

3 · solidworks sheet metal basics

4 · solidworks corrugated sheet metal

5 · solidworks convert to sheet metal

6 · sheet metal solidworks tutorial

7 · sheet metal drawings solidworks

Metal fabrication is the process of manufacturing sheet metal and other flat metals to make them conform to specific shapes. The process starts with sheet metal around a quarter of an inch thick or less. At this thickness, the metal is pliable enough to assume different shapes.

You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, .You can calculate the developed length of sheet metal parts using bend calculation .There are specific sheet metal features you can use to create sheet metal bodies .Sheet metal parts display the Sheet-Metal feature in the FeatureManager design .

Sheet metal gauge/bend tables store properties for a designated material. A .

For sheet metal parts, you can choose Flattened-Mass in the Cut-List .When designing sheet metal parts, the order preference for use of feature tools .

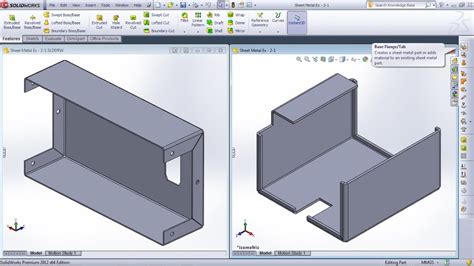

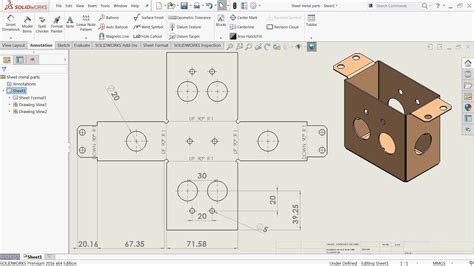

She’ll review new and enhanced features in SOLIDWORKS Sheet Metal from the . In this video Author Alejandro Reyes demonstrates how to create a sheetmetal box using SOLIDWORKS 2016. This video is from the book Beginner's Guide to SOLIDWORKS 2016 - Level II. This book.

solidworks sheet metal pdf

Recognizing Different Entities. Recognizing Mirror Patterns. Hem and Edge Flange Limitations. Search 'Sheet Metal' in the SOLIDWORKS Knowledge Base.Sheet metal gauge/bend tables store properties for a designated material. A single table lets you associate a bend allowance, bend radius, or k-factor with any combination of thickness, bend . Exercise 11 - Introduction to Sheet Metal creation in Top-Down Assembly mode, using forgotten shell technique.

43.7K subscribers. Subscribed. 7. 3.6K views 8 years ago 3D CAD & Design. This Video will show the changes in SOLIDWORKS 2016 in regards to Sheet metal as spelled out in the "whats new".

allows you to quickly create sheet metal part designs using a simple design process, saving you time and development costs, thanks to specific sheet metal features.

When designing sheet metal parts, the order preference for use of feature tools are as follows: 1. Use sheet metal features such as base-flanges, edge-flanges, miter flanges, etc. 2. Use the . She’ll review new and enhanced features in SOLIDWORKS Sheet Metal from the last few years, as well as provide a more in-depth look at: Gauge and Bend tables, Custom Properties, and Costing. This session is designed .For sheet metal parts, you can choose Flattened-Mass in the Cut-List Properties and Summary Information dialog boxes. Flattened mass is calculated based on the model's flat pattern. . http://www.sdcpublications.com/SOLIDWORKS In this video Author Alejandro Reyes demonstrates how to create a sheetmetal box using SOLIDWORKS 2016. This video .

When you mirror features and bodies in a sheet metal part, many of the bends are mirrored as well. The only bends that are not mirrored are those that are normal to and coincident to the mirror plane; those bends are extended. . Help Content Version: SOLIDWORKS 2016 SP05 To disable help from within SOLIDWORKS and use local help .Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. Assigning Punch IDs. You can add punch IDs to forming tools for easier identification in punch tables. . SOLIDWORKS 2016 SP05 To disable help from within .Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .If you create a sheet metal gauge table, use a semi colon - ; - as a delimiter between values. With gauge tables, the radii and angles can differ. However, you must list the thickness and radii values in ascending order. . Help Content Version: SOLIDWORKS 2016 SP05 To disable help from within SOLIDWORKS and use local help instead, .

In the FeatureManager design tree, select the part and click Flatten (Sheet Metal toolbar). In the cut list, right-click the body and click Flatten. . Help Content Version: SOLIDWORKS 2016 SP05 To disable help from within SOLIDWORKS and use local help instead, .There are specific sheet metal features you can use to create sheet metal bodies quickly. However, in some circumstances when the design requires certain types of geometry, you can use non-sheet metal feature tools, then insert bends or convert the part to sheet metal. . SOLIDWORKS 2016 SP05 To disable help from within SOLIDWORKS and use .Solidworks 2016 Sheet Metal . LS By Larry Schulties 01/14/16. Anyone having issues with sheet metal module. When I create a base feature and then try to add flange or flanges to base feature, Solidworks crashes. All other modules and functionality seems to be working fine. This started only after upgrade from 2015.The illustration shows a single tab feature that adds two tabs to the sheet metal part. The sketch must be on a plane or planar face that is perpendicular to the direction of thickness of the sheet metal part. You can edit the sketch. . SOLIDWORKS 2016 SP05 To disable help from within SOLIDWORKS and use local help instead, .

In the SOLIDWORKS 2016 example above, you can see the same Swept Flange part but with both Cut Features being mapped correctly onto the Flat Pattern and not requiring any features to be added directly to the Flat Pattern. It is easy to see how anyone who uses the sheet metal Swept Flange often will take full advantage of this fantastic enhancement to make the .

You can create notches across bends in flattened sheet metal parts. In manufacturing, bend notches help manufacturers determine where to put the press brake. You can use notch features on all bends so the bending operator can then use them to .

Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody . On this snippet from the March 2016 episode of "Straight From Support", SOLIDWORKS Applications Engineer Heather Dawe explains the differences between the "C. Sheet metal parts can have sketches in the Folded and the Flat Pattern states (Fig. 1) Sketches created in the folded state can have an equivalent “transformed” sketch in the Flat Pattern state. . He began his career with SolidWorks over 15 years ago. He started in R&D working on many of the new functionalities developed at the time .

With SOLIDWORKS 2016 – Sheet Metal, problem fixed! Yeah! We hope this part of the What’s New series gives you a better understanding of the new features and functions of SOLIDWORKS 2016. Please check back to the .Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal part. Creating Sheet Metal Flat Pattern Configurations. You can create a configuration in a sheet metal part that shows the flattened part.

> Sheet Metal > Sheet Metal Parts > Cutting Across Sheet Metal Bends. SOLIDWORKS Help Other versions: | Print | Feedback on this topic : Introduction: Administration: User Interface: SOLIDWORKS Fundamentals: Moving from 2D to 3D . SOLIDWORKS 2016 SP05 To disable help from within SOLIDWORKS and use local help instead, .If the forming tool has radii that are pushed into the sheet metal body, then the forming tool will fail when the concave radius is smaller than the material thickness. In this case the radius that gets pushed into the sheet metal body becomes negative and forces the tool to fail. . SOLIDWORKS 2016 SP05 To disable help from within .Sheet-Metal contains the definition of the sheet metal part. This feature stores the default bend parameter information (thickness, bend radius, bend allowance, auto relief ratio, and fixed entity) for the entire part. . SOLIDWORKS 2016 SP05 To disable help from within SOLIDWORKS and use local help instead, .Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .

This Video will show the changes in SOLIDWORKS 2016 in regards to Sheet metal as spelled out in the "whats new" PDF.Presented by Cory HoldenFor more infor.Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .

Now in SOLIDWORKS 2016 for sheet metal parts, you can choose Flattened-Mass in the Cut-List Properties and Summary Information dialog boxes. Flattened mass is calculated based on the model’s .Open a sketch on the face of a sheet metal part where the new wall will be attached. Select a linear edge of a planar face on the model to attach the wall to, . Help Content Version: SOLIDWORKS 2016 SP05 To disable help from within .Flatten Sheet Metal Part Example (VBA) . 2016 SP05 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help. To report problems encountered with the help interface and search, contact your local support representative. To provide feedback on individual help topics, use the “Feedback on .In the Convert to Sheet Metal PropertyManager, you specify the fixed face and thickness of the sheet metal part, the default bend radius, and the edges or fillet faces on which to create bends. If an edge already has a fillet applied, the radius of the fillet is used as the bend radius for the new sheet metal part. The software automatically selects the edges on which rips are applied.

rip edge sheet metal

Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .

rittal junction box ip68

Steel gauges help manufacturers measure the thickness of metal. Accurately measuring the thickness of steel is a crucial part of the manufacturing process. But how do you measure steel thickness and what should you look at when buying a BBQ? What type of gauges are used? And why are accurate steel thickness measurements so important?

solidworks 2016 sheet metal|sheet metal solidworks tutorial