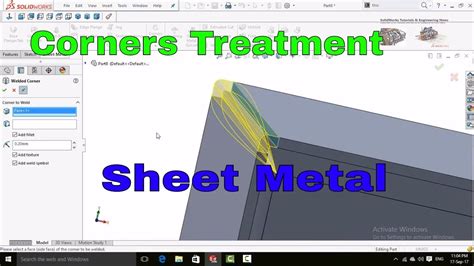

how to weld a sheet metal corner shut in inventro The Corner tab lets you override default parameters in the Sheet Metal Styles dialog box. You can specify the corner relief shape for a 2 or 3 bend corner. You can also specify the relief size, . Learn about the wiring diagram for a junction box lighting circuit. Understand how junction boxes are used to connect and distribute electricity for lighting fixtures in your home or building.

0 · sheet metal corner welding

1 · sheet metal angle welding

2 · override sheet metal corners

3 · how to corner sheet metal

4 · editing corners in sheet metal

5 · autocad sheet metal corners

What Skills Do I Need to Be a Metal Fabricator? To be a metal fabricator, you need to be detail-oriented in your work and be committed to producing quality parts, especially when clients require a certain level of precision. Other qualifications include manual dexterity, some math skills, physical strength for occasional lifting, and physical .

In a future release we are working on providing an "arc weld" corner relief type that should make this easier but you would still need to place the sheet metal part into a weldment.iam to use Inventor's welding tools.

Inventor - Weld corner exampleThe Corner tab lets you override default parameters in the Sheet Metal Styles dialog box. You can specify the corner relief shape for a 2 or 3 bend corner. You can also specify the relief size, . Instead use the pencil icon and create sheet metal default for your company thickness. That way you have a dedicated style for each thickness of . Change to Linear weld, and gap to 0.1mm. This should automatically set your corners 0.1mm without doing corner seam, since physical bending will not easily achieve a 100% angle precision, 0.1mm is acceptable.

You can create a corner seam or rip an existing corner seam between sheet metal faces. To create a three-bend corner, you can use Corner Seam or Auto-Miter. Check out the Sheet metal capabilities of Inventor Professional in this session. How to setup Sheetmetal defaults?Working with corners and bending rules.How .

Consider using the Corner Seam tool within the Inventor Sheet Metal environment to "prep" the edges so that you can create a bend between two disjointed faces.On the ribbon, click Sheet Metal tab Create panel Flange. Select two coplanar edges that share a virtual corner. In the Flange dialog box, Corner tab, verify that Apply Auto-Mitering is selected. .

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

Yeah, we have been manufacturing it for years but the problem it not always 100% so I'm trying to improve it by using on Inventor. I forgot to take other photo of otherside of corner radius as it already on way to customer. Check out more tips and articles here www.ketiv.com/blog/In this week's video, Jonathan Landeros of KETIV Technologies shows how you can create a sheet metal. I just started working with sheet metal in Inventor (2020) and am currently modeling the baseplate of my circular saw as I intend to design a dust collection shroud for it. I've been able to model the part with a sketch; I formed .

To change the corner seam gap, you need to change the seam gap in sheet metal defaults. Click on sheet metal defaults to open, then change Miter/Rip/Seam gap as i have circled in the picture below. Change to the size you need it to be. I have as .1 to get the corner seam as close as it can be. Hope this solves your problem. Consider using the Corner Seam tool within the Inventor Sheet Metal environment to "prep" the edges so that you can create a bend between two disjointed faces Could anyone help please, I'm using Inventor 2008 Pro in the sheet metal format, and having a slight problem with corners!! The guys in the workshop are telling me that when they bend up an enclosure the edges of the flanges are always corner to corner. I've been trying to achieve this by creatin. Will this work? I just made corner seams with a width of .001" then added the bend. I hade to delete the faces on the edge and have them heal on the 2 parts that are parallel. Also make sure all the sheet metal thickness is the same from one file to the next or things won't work right. Hope this is what you want.

On the ribbon, click Sheet Metal tab Modify panel Corner Seam. Select a model edge on each of two adjacent sheet metal faces. Accept the default seam type or select another of the three seam types. In the Corner Seam dialog box, you can: Use the Face/Edge distance measurement method instead of the defaulted Maximum Gap Distance method. . Issue: Is it possible to create the reentrant corner in Inventor sheet metal part and get flat pattern? To obtain this corner, there will be a lack of material, is it possible to obtain the flattening of the sheet metal with the cutting line and possibly the shape of . The only way I found to make it look "right" is to choose Arc Weld for the corner relief shape. Sam B Inventor 2012 Certified Professional Please click "Accept as Solution" if this response answers your question.-----Inventor Professional 2013 SP1.1 Update 1 Windows XP Pro 32-bit, SP3 HP EliteBook 8730w; 4 GB RAM; Core™ 2 Duo T9400 2.53 GHz . HOW TO MAKE SHEET METAL ELBOWS 90degree in INVENTOR 2018

Learn how to roll sheet metal in Autodesk Inventor with step-by-step instructions and tips for creating curved designs and geometric shapes with precision. P.About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

You can model the corner with the Cut across Bend feature: select one of the faces of ContourFlange1 to create a sketch and "flat project" the faces adjacent to the corner. Then model your relief as sketch profile and use Cut across Bend to cut it (pictures and R11 part are attached) Lucia Casu Inventor Part Modeling About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright . Inventor Forum > sheet metal corner; Inventor. Community Forums; Inventor Forum . In your derived part, you may be able to use Delete Face with Heal checked to remove the surfaces in the weld gap and corner relief and have Inventor smooth over the result. Sam B Inventor Professional 2017 R2 Vault Basic 2017 Windows 7 Enterprise 64-bit, SP1 . How to define a custom sheet metal iProperty with thickness and classify sheet metal parts according to it in Inventor? How to export this classified list to excel? Inventor can create specific custom iProperties and classify by .

Not sure what program you're using, but look for corner treatments. There should be 2-bend and 3-bend corner treatments, and you should be able to set it to "close" the corner, which will bring the 2 edges together. Be aware that it can be difficult to actually form in real life like that, so talk to whoever's running your press brake.

sheet metal corner welding

Learn how to use Autodesk Inventor's sheet metal contour flange feature in this quick tip video. https://www.youtube.com/channel/UCjd_zIvYtQymk0dPx3vTJcA/joinYou Can Support our Channel for more tutorials, We Provide SolidWorks, .

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright . AUTODESK INVENTOR Basic Training Tutorial (Full Course 7hr:55min) playListhttps://www.youtube.com/playlist?list=PLx-VY2mDlK2HgGR4Oell7SPeIAd0KbIFhAUTODESK I. Learn autodesk inventor 2023 basic tutorial for beginner how to working with sheet metal#inventor #sheetmetal #mufasucad

I haven't done anything for welding in inventor. Solved: I was wondering how to add spot welds to an assembly drawing step by step? I haven't done anything for welding in inventor. . I see sheet metal prints where the proper symbol will be used at the location, then have an X located at preferred locations for the actual welds. Chris. Reply.

Join Thom Tremblay for an in-depth discussion in this video, Using the corner seam to improve parts, part of Inventor: Sheet Metal Design. Would like to check if there is a possibility to remove a sheet metal style created in Inventor. If so, what is the procedure? How to remove a sheet metal style from an Inventor file. Open the sheet metal file in Inventor. Access the Sheet Metal defaults. In the Sheet Metal defaults select the pencil for the sheet metal rules. In the Style and Standard Editor, check the option in . First create a sheet metal part. If needed a flat panel layout (not really necessary). Save the part. Open a new weldment Assembly. Place the sheet metal part into the assembly. More than likely you'll want to use the "goove" option to fill in the gaps. I would tend to believe that the same option would apply if joing two sheet metal pieces .

sheet metal bender home depot

Use a 4" hole saw in drywall, then gently pound the junction box into the drywall. But be sure to use a block of scrap wood over the junction box, so the gently pounding is evenly distributed over the entire junction box. If there is plywood behind the drywall, you'll want to use 4 1/8" hole saw.

how to weld a sheet metal corner shut in inventro|how to corner sheet metal