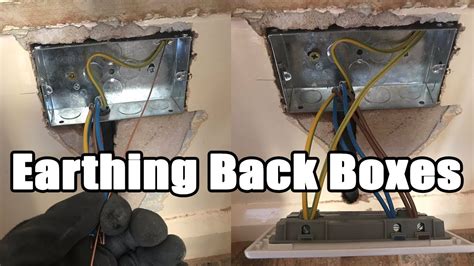

earthing metal back boxes regulations z Electrical installations and earth bonding should be carried out in accordance with BS 7671 ‘Requirements for electrical installations’. The earth wire(s) should be connected to the earth . Pure metal / Used as an alloy element for aluminum, lead, zinc, and other .

0 · metal back box earth connection

1 · metal back box earth bonding

2 · electrical back box requirements

3 · earth wire on back box

4 · earth bonding boxes electrical

5 · earth bonding boxes

6 · earth bonding box requirements

7 · earth bonding back boxes

What Are Steel Coils? Steel coils are long, thin sheets of steel that are used in a variety of applications. They are produced by rolling steel at high temperatures and can be found in a variety of industries, including construction, automotive, and .

n Electrical installations and earth bonding should be carried out in accordance with BS 7671 ‘Requirements for electrical installations’. Answer For metal back boxes which are fully recessed and covered by the faceplate: Sockets, fused spurs, etc The earth wire(s) should be .z Electrical installations and earth bonding should be carried out in accordance with BS 7671 ‘Requirements for electrical installations’. The earth wire(s) should be connected to the earth . Answer: The ECA recommendation is that metal back boxes should be earthed. However, the IEE guidance notes state that if the metal back box has at least one 'fixed' front . A metal back box for a socket would be classed as an exposed-conductive part and as such it needs to be earthed. If the back box has a fixed lug on one side then the .

If I fit metal back boxes for light switches and sockets, do I need to connect the earth wire to the back box or the earth wire only goes to the back of the socket or switch? I will .

"The Wiring Regulations National Committee has agreed that such boxes may be earthed via the tight metal-to-metal contact of the screw in the fixed lug. Consequently, unless . Regulation 543.2.7 of BS 7671 requires an earthing tail to be fitted where the cpc associated with the circuit wiring from the distribution board to the socket-outlet is formed by .

The back boxes do have a solid lug so the "and" of "or/and" applies. There are both metallic and non-metallic faceplates but for both types the accessory mounting scews ARE connected by design to the CPC via the earth . Therefore, such back boxes, no less than every other exposed-conductive-part, are required to be earthed in accordance with Regulations 411.4.2 (TN systems) and 411.5.1 (TT .

metal back box earth connection

n Electrical installations and earth bonding should be carried out in accordance with BS 7671 ‘Requirements for electrical installations’. Answer For metal back boxes which are fully recessed and covered by the faceplate: Sockets, fused spurs, etc The earth wire(s) should be connected to the earth terminal on the socket. Light switchesz Electrical installations and earth bonding should be carried out in accordance with BS 7671 ‘Requirements for electrical installations’. The earth wire(s) should be connected to the earth terminal on the socket.BS 7671:2018 regulations are with regards to the installation pipework and not the service pipework. It should be verified if parts are deemed to be extraneous-conductive-parts before there may be a requirement to connect them to the MET.

Answer: The ECA recommendation is that metal back boxes should be earthed. However, the IEE guidance notes state that if the metal back box has at least one 'fixed' front plate fixing lug, then they do not need to be earthed.

A metal back box for a socket would be classed as an exposed-conductive part and as such it needs to be earthed. If the back box has a fixed lug on one side then the answer is that it will become earthed via the mounting screws .

If I fit metal back boxes for light switches and sockets, do I need to connect the earth wire to the back box or the earth wire only goes to the back of the socket or switch? I will be installing MK sockets and switches. "The Wiring Regulations National Committee has agreed that such boxes may be earthed via the tight metal-to-metal contact of the screw in the fixed lug. Consequently, unless both lugs are of the adjustable type, it is not necessary to connect the earthing terminal of the accessory to the earthing terminal .." Regulation 543.2.7 of BS 7671 requires an earthing tail to be fitted where the cpc associated with the circuit wiring from the distribution board to the socket-outlet is formed by metallic conduit, trunking or ducting, or the metal sheath or armour of a cable. The back boxes do have a solid lug so the "and" of "or/and" applies. There are both metallic and non-metallic faceplates but for both types the accessory mounting scews ARE connected by design to the CPC via the earth in the socket.

Therefore, such back boxes, no less than every other exposed-conductive-part, are required to be earthed in accordance with Regulations 411.4.2 (TN systems) and 411.5.1 (TT systems).n Electrical installations and earth bonding should be carried out in accordance with BS 7671 ‘Requirements for electrical installations’. Answer For metal back boxes which are fully recessed and covered by the faceplate: Sockets, fused spurs, etc The earth wire(s) should be connected to the earth terminal on the socket. Light switchesz Electrical installations and earth bonding should be carried out in accordance with BS 7671 ‘Requirements for electrical installations’. The earth wire(s) should be connected to the earth terminal on the socket.BS 7671:2018 regulations are with regards to the installation pipework and not the service pipework. It should be verified if parts are deemed to be extraneous-conductive-parts before there may be a requirement to connect them to the MET.

Answer: The ECA recommendation is that metal back boxes should be earthed. However, the IEE guidance notes state that if the metal back box has at least one 'fixed' front plate fixing lug, then they do not need to be earthed. A metal back box for a socket would be classed as an exposed-conductive part and as such it needs to be earthed. If the back box has a fixed lug on one side then the answer is that it will become earthed via the mounting screws . If I fit metal back boxes for light switches and sockets, do I need to connect the earth wire to the back box or the earth wire only goes to the back of the socket or switch? I will be installing MK sockets and switches. "The Wiring Regulations National Committee has agreed that such boxes may be earthed via the tight metal-to-metal contact of the screw in the fixed lug. Consequently, unless both lugs are of the adjustable type, it is not necessary to connect the earthing terminal of the accessory to the earthing terminal .."

Regulation 543.2.7 of BS 7671 requires an earthing tail to be fitted where the cpc associated with the circuit wiring from the distribution board to the socket-outlet is formed by metallic conduit, trunking or ducting, or the metal sheath or armour of a cable.

The back boxes do have a solid lug so the "and" of "or/and" applies. There are both metallic and non-metallic faceplates but for both types the accessory mounting scews ARE connected by design to the CPC via the earth in the socket.

electrical box height kitchen

electrical box gfci

Westfield Sheet Metal Works, Inc., located in Kenilworth, New Jersey, has been in existence since 1928 as a union shop affiliated with Sheet Metal Workers Union Local 22. Our 50,000 square foot manufacturing and office facility, located on a 100,000 square foot lot, is equipped to service your metal fabrication needs from design to installation.

earthing metal back boxes regulations|earth bonding box requirements