welding sheet metal with mig hobart 140 So far this Hobart Handler 120 unit seems to weld just great, although i am still getting my hands used to mig welding, and getting the rust out. I am running some test welds . $326.12

0 · hobart welder parts catalog

1 · hobart handler 140 welding chart

2 · hobart handler 140 replacement parts

3 · hobart handler 140 parts manual

4 · hobart 140 welder parts list

5 · hobart 140 parts list

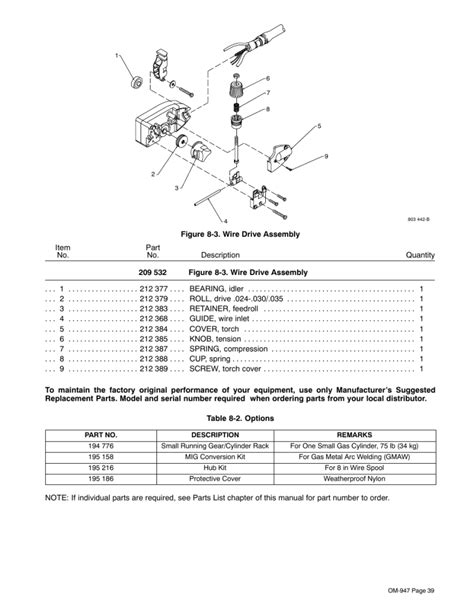

6 · hobart 140 parts diagram

7 · hobart 140 mig welder manual

Used Vertical Machining Center Inventory Updated Daily, Used CNC VMC For Sale, Haas VMC, & Mazak VMC

Today we are going to be welding thin sheet metal to replace old rusted out metal on our 1951 Chevy Panel van.Follow requirements in OSHA 1910.252 (a) (2) (iv) and NFPA 51B for hot work and have a fire watcher and extinguisher nearby. Read and understand the Safety Data Sheets (SDSs) and .

These documents can provide the welding parameters necessary to complete a weld correctly and consistently for a given application and joint design. A WPS offers the recommended operating window — or maximum and minimum .

Welding sheet metal please help. 10-27-2007, 09:16 PM. I am trying to weld 22 gage sheet metal with a Hobart 140. I am using Argon CO2 with solid .030 wire. It keep . So far this Hobart Handler 120 unit seems to weld just great, although i am still getting my hands used to mig welding, and getting the rust out. I am running some test welds .Durable MIG Welder: The Hobart Handler 140 MIG Welder combines durability & portability,. Versatile Welding Capability: With the ability to weld up to 1/4 inch mild steel, Hobart. User-Friendly Setup: The inclusion of a Quick Select drive .

Can a Hobart 140 spot weld 16 or even 14 gauge car frame material? I dont really want to return this 140 and spend another 0 on top for a 220v welder. I've reviewed the Spot Weld page (plug-weld) , though helpful it .

Butt Welding Sheet Metal With A Mig Welder. Greg's Garage. 65K subscribers. 2.2K. 564K views 11 years ago. HOBART HANDLER 140 WELDER - http://amzn.to/2vS6EQL WELDING VICE GRIPS -.

Preventing burn-through and warping when welding sheet metal is all about controlling the heat. Choose the right welding process and filler metal, and follow these common tips to help ensure success. Mig and Flux Core - gas metal arc welding & flux cored arc welding . i'm currently using a hobart 140 handler on 75/25 bottle.i'm looking to do patch panel repair and i'm concerned about the correct heat and speed settings for this.does anyone out there have any experience in this situation? also i'm using .024 wire. thanks for any help .

The Hobart Handler 140 device uses a 10-feet MIG gun to operate the welding, which makes it easy to weld mild and stainless-steel metal. Voltage Five Position Selector You have five voltage settings with the Handler 140, . Just ordered a Hobart 140 and need to choose solid wire. I have an 80cf bottle being hydro'd, revalved and filled with ArCo2 75-25. . which mig wire for auto body sheet metal . This was my second actual MIG weld I done going from the sheet metal to 1/4" box tube. Reply . Quick Navigation MIG, TIG, Stick, And Oxy/Fuel Welding Top. Site Areas . Talk about MIG welding equipment, guns, drive-roll systems, solid and flux-cored wires, etc. . I recently purchased a Hobart 140 and just realized although I have welded many times I have never been the one to buy the gas or wire and now that I'm on my own I am clueless. I will be predominantly working with sheet metal for my vehicles .Flux core has it's uses, but any real mig machine can run flux core (with the right rollers) when you need it. I really like Hobart, they're usually just Miller parts from a few generations back and they weld beautifully. I used to teach welding newbs on Hobart handler 210 .

hobart welder parts catalog

The American Welding Society (AWS) defines it as 3/16 inch or thinner in its AWS D1.3/D1.3M: 2018 Structural Welding Code – Sheet Steel. As when welding other materials, getting the best results with thin materials depends on correct voltage, amperage and travel speed — .

hobart handler 140 welding chart

Select the department you want to search in . In this video I show you how to properly set up your welder settings for thin sheet metal welding on automotive car or trucks repairs for beginners.In this v. Get a decent mig welding machine, preferably a good 115 volt mig welder like a Hobart Handler 140. (Actually, 115 volt mig welders are often the best choice for welding sheet metal and a Hobart Handler 140 has all the features needed to weld thin sheet metal or even up to ¼" thick steel.) Get a gas conversion kit so you can run .023" bare wire.There seems to be much difference of opinions on which size wire works best on sheet metal (22 g- 18 g) I've always used .030 in my MM210, harris 20 gauge in my 110 machine. . Hobart Handler 140 - Great 120V Mig Hobart Handler EZ125 - IMO the best 120V Flux Core only machine . but again I do use it if I have it and its the only reel I have .

A few days ago I bought a Hobart 140, a 5 liter tank (75% CO2 – 25% Argon) and 0.030 solid copper wire. I never welded before and have been practicing butt welds on the old floor pans I cut out of my 67 GTO. After setting up my equipment and reading the manual, I read that I should have bought a gas mixture of 75% Argon – 25% CO2 (rather than the mixture I .

Description OM-258267H 2020−07 Processes File: MIG (GMAW) Handler 140 Arc Welding Power Source And Wire Feeder MIG (GMAW) Welding Flux Cored (FCAW) Welding www.HobartWelders.com With the Handler 140, you can MIG weld aluminum. But only in the 20 to 16 ga. Range. . The fine print of Hobart Handler 140 spec sheet notes that you must keep the MIG lead as straight as possible and that the wire feed-ability is not as good when welding steel. . One of the things users note with the Handler 140, is the wire feed system .

Mig is alittle better for sheet metal. But when you take into account the additional costs like the machine, regulator and bottle of gas your looking at almost an additional 1000 just to get started. I've welded 29 gauge sheet metal with fluxcore it's doable.

I've been trying to weld 3/16 steel with a handler 140 but can get sufficent penetration. I have tried solid .035 with 75/25 and flux core .030 with no gas. . Thermal Dynamics Cutmaster 52 Plasma * Lincoln 175 MIG . Hobart HH 125EZ. Comment. Post Cancel. buggsz24. Junior Member. Join Date: Nov 2004; Posts: 25; ShareFor MIG welding sheet metal, it is often recommended to use an electrode wire of the smallest diameter to prevent burn-through and warping. The main reason to use a smaller diameter wire is that it takes less heat for melting and hence the . The Eastwood MIG 135 offers entry-level MIG welding experience just like Hobart 140. Its maximum output amperage of 135A and the duty cycle of 20% at 90A can handle small DIY welding jobs only, while the Hobart provides .

I'm getting ready to pull the trigger on a 110 volt MIG welder. I have a flux core now and its time to upgrade to start learning how to do some nicer welds as well as have something that I can weld sheet metal with. . The Hobart 140 is . MIG, TIG, Stick, And Oxy/Fuel Welding; Cheapest Gas Mig for Sheet or tin metal? Hobart Handler 125 vs 140 vs used old Migs? Welcome to Welding.com, the ultimate Source for Welding Information & Knowledge Sharing! Here you can join over 40,000 Welding Professionals & enthusiasts from around the world discussing all things related to Welding .

steel cabinet for sale makro

I recently bought a 140 specifically for welding sheet metal (20 gauge) for automotive panel replacement. I also bought some .023 wire and tips but found out that I need a new drive roller to feed the wire. I read here that I need at new roller "Hobart Drive Roll V Smooth Solid Wire 237338" but that is spec'd for .024-.035 wire only.

steel cabinet doors

The Hobart Handler 140 is among the smallest MIG welders produced by the Hobart Company, making it highly appropriate for DIY project enthusiasts and homeowners looking to perform small to medium repair and maintenance tasks.. The Hobart handler weighs just 57 pounds and runs off a 110v power source, making it convenient to use and move in different areas around your . Packed with the latest IGBT inverter technology and quality features, the Eastwood MIG 140 delivers precision welds on sheet metal and other light steel and stainless steel projects up to 3/16-in. thick. This versatile 140-Amp welder runs on conventional 120V household power (or by generator) and weighs less than 25-lbs for go-anywhere portability.

Hobart Handler 210 w/DP3035 - Great 240V small Mig Hobart Handler 140 - Great 120V Mig Hobart Handler EZ125 - IMO the best 120V Flux Core only machine Miller Dynasty 200DX with cooler of my design, works for me Miller Spectrum 375 - Nice Cutter While sheet metal is primarily a TIG welding job, there are times when it’s handy to have an available MIG welder to fuse sheet metal. The Hobart Handler 140 MIG is the best affordable MIG welder for sheet metal. It’s one of the highest-quality machines available and comes incredibly low-priced.

MIG, TIG, Stick, And Oxy/Fuel Welding; Hobart 140; Welcome to Welding.com, the ultimate Source for Welding Information & Knowledge Sharing! . 140 is just a sheet metal machine- sure you can do a wee bit thicker stuff but for . Eastwood 135 and Hobart 140 are welders that use MIG welders for welding sheet metal. The two welders run with a standard amount of volts which run up to almost 240V with the size of their casings, and they are lightweight since they weigh almost 60 kilograms.Handler®140 115-Volt Wire Feed Welder 217919 September 2022 500559 115 V Quick Specs Welding Amp Range 25–140 A Rated Output 90 A at 18.5 VDC, 20% duty cycle Mild Steel Thickness Range 24 ga.–1/4 in. Hobart Welding Products An ITW Welding Company Sales: 800-626-9420 Service: 800-332-3281 HobartWelders.com

hobart handler 140 replacement parts

Search for used modular cabinets. Find Advance, Easy Kleen, Stanley, Global Industrial, and Heraeus - Hanau - Vötsch for sale on Machinio.

welding sheet metal with mig hobart 140|hobart 140 mig welder manual