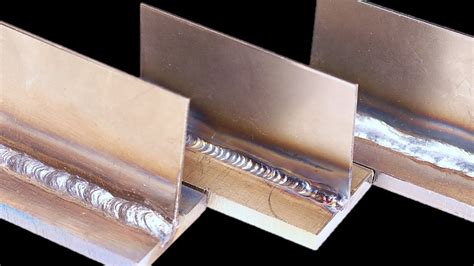

welding thin sheet metal with stick rods This video shows you how to stick weld on thin metal with 7018 electrodes. These are 3/32 size rods that I'm using and the plates are a little bit thinner th.

Junction boxes come in various types, each designed for specific applications and environments. Understanding the different electrical box types and their uses is crucial for anyone involved in electrical work or home improvement projects.

0 · welding thin metal to thick

1 · welding stainless steel sheet metal

2 · welding 20 gauge sheet metal

3 · mig welding thin metal videos

4 · mig welding thin metal settings

5 · best welding for thin metal

6 · best welder for thin metal

7 · arc welding automotive sheet metal

Volumetric Modular: Wood or steel boxes manufactured in a factory and delivered to a jobsite complete with the majority of the interior fixtures, finishes and systems. Can come with limited exterior finishes too. Panelized: Interior and exterior walls/floors/roofs constructed with windows, doors, drywall, finishes and limited MEP.

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc . Rod diameter shall be as thin as possible, so 1/8″ or 1/16″ diameter electrodes are good options. In this article, I will discuss the step-by-step process of stick welding sheet metal, as well as the electrodes and settings I would . Learn essential tips for beginners on how to stick weld thin sheet metal effectively. Discover the right gauge, techniques, and rod choices for successful welding.Stick welding thin sheets of metal requires an electrode that is both forgiving and has a high deposition rate. The best rods for the job can be either a ⅛ inch 6011 or a 6013 rod. If you are working with a surface with rust or paint then the 6011 .

Click the link to vice my latest video on Stick Welding Thin Material with Small Electrodes: https://www.youtube.com/watch?v=RqzqdKMgOqc This video shows you how to stick weld on thin metal with 7018 electrodes. These are 3/32 size rods that I'm using and the plates are a little bit thinner th. Any stick welding rod is going to have more arc force than 22 gauge can handle. By the time you get a nice arc established you already burned trough the metal. . But for your question, welding really thin sheet metal (anything . 0 How to Weld Thin Metal: A Step-By-Step Guide (2024) Last Updated on Jan 03 2024. Working using thinner metal sheets is complicated. Excess heat may lead to burnout.

thin metal welding tricks that not all know. why didn't the welder tell this secretThis is a square tube welding technique, especially how to weld thin squar. I have very limited experience stick welding anything thinner than 1/8" thick. I would like to use 20 or 22 gauge to keep the weight down; 18 gauge is an option if 20 or 22 is too thin. I don't see a backsplash needing a lot of structural strength. I can bend the backsplash in a sheet metal brake but the ends will be welded on. Stick Welding Sheet Metal with 6013 rods! Beginner Welding Series! This is the thinnest sheet metal I have ever welded using this process. I'm welding very . Many times, I have difficulty stick welding thin steel/sheet metal without burning a hole in it. While I realize tat MIG or TIG would be better, are there any tips/tricks that result in an acceptable stick weld of this material? . Dip the fill rod like you were tigging or if welding flat lay the bare rod flat & run over the top of it .

A fun challenge to test the limits of stick welding thin metal while providing 4 practical tips. Stick welding is great because of the simple equipment, port. 1.6mm rods which are any good are not cheap and are hard to find. It will take a lot of practice. I assume you have to weld vertically and in all sorts of uncomfortable positions. It's not easy to weld thin metal with arc and 50A will probably be too high. What happens if you try it and make a mess of it, (which is not unlikely)? Smaller diameter welding rods are hard to run and not regularly used because stick welding produces a lot of heat and it’s easy to burn through thin metal. If you aren’t sure which type of electrode to buy then look at our comparison of .

Stick Welding Equipment To Weld Thin Metal Like other welding methods, you won't need the most powerful Stick welder to weld thin sheet metal. Instead, you can do it with a YesWelder ARC-125DS DC Stick welder, rated at 20-125 amps with an easy arc start technology. . YesWelder The next step will be selecting the right Stick welding rod. You .

welding thin metal to thick

Welding thin sheet metal with a stick welder is a skill on its own and needs quite a bit of practice to master. What’s the most common welding rod? The most common welding rods are 6010, 6011, 6013, 7018, and 7024 while the most common . This makes them a great choice when working thin sheet metal, poor-fitting weld joints, and light repair welding. It creates less smoke than the two cellulosic electrodes above, but it leaves a thicker slag. . This low hydrogen rod produces the highest quality weld metal from mild steel stick rods. Additionally, it sustains relatively high . Related reading: Best Stick Welding Rod for Thin Sheet Metal welding. Stick welding of sheet metal shall be carried out using AWS A5.1/A5.1M E6013 (CWB/CSA W48-06 E4313) type electrode of diameter 5/64 inch or 2.0 .

yes they sell 1/16" or 1.5mm dia rod 6013 is easiest to get. some comes in long length and tends to vibrate when arc first started.. thin metal means joint gaps should be as small as possible. usually tack weld close together hammering joints tight. weld short distances and let metal cool off. try not to weave but travel fast and in straight line. nothing wrong with weaving . How to weld thin gauge steel similar to car body panel, down to .8mm or 1/32 of an inch thick with arc or stick welder.DisclaimerDue to factors beyond the c.Collect welding rods for the welding. Try to get E6018 or E7018 1/16”. Before you start to weld, it needs to be baked. Get thin sheet metal of 0.021”. This thickness is perfect for welding with an arc welder. [amazon bestseller=”Arc Welder” items=”3″ template=”table”] Practice Before You StartIn this article, we present crucial tips for welding thin metal, exploring the unique challenges of welding thin metal, and providing practical tips to help you overcome them. . Stick Welding Thin Metal. . TIG welding thin sheets will require a smaller diameter, .020, .040, and 1/16-inch ceriated or thoriated tungsten. These electrodes .

6.Try and AVOID welding sheet metal.If you have to weld on it, use that firepower sparingly. Practice your fab skills ; you can bend smaller sections with clamps and a vice, you can drill sheet metal with an inexpensive (3/8") drill, you can get away with tack-welding connections without a final seal-weld, you can rivet sheet metal. Stick Welding/Arc Welding - Shielded Metal Arc Welding Stick Welding Tips, Certification tests, machines, projects . However, 6011 can run a little lower on amps so 3/32" material is still ok with 1/8" rod in my opinion. I've repaired thin sheet on a cattle trailer with 3/32" 6011 by using an overlapping tacking method at about 65 amps. The first step to successfully stick welding thin sheet metal is selecting the right electrode. For beginners, it’s best to start with rutile rods like E60 or E70. . For welding thin sheet metal, it’s crucial to work on low amperage to prevent burning through the metal. The 708 and 60 rods are preferred for this type of welding. Even when welding new metal to thin rusty stuff, it's only as strong as the old thin stuff. One of the problems with the MIG is that the weld is very hard compared to the parent steel so it takes some patience grinding the welds so as not to go through the old metal.

If so, this Hy-weld stick welding rod can show reliable performance. It can penetrate through thicker materials effortlessly. Whether the base metal is made of steel, stainless steel, cast iron, or aluminum, this versatile welding rod is well-suited. . Welders usually use it for welding thin metal sheets, galvanized steel, low alloy steels . Of relevance to industrial strength welding jobs, the rods produce thicker welds and have a higher tensile, plus a chemistry that reduces hydrogen embrittlement. . Thicker electrodes are best for welding thicker metals, while thin electrodes are ideal for thin sheet metal. Stick electrode codes, which provide information about core .SUBSCRIBE for new videos every Monday and Friday: https://goo.gl/FRdNssWhen most people think about welding light gauge material, they think TIG or in some .

welding stainless steel sheet metal

Hi everyone, after my cl find sitting in the shed for past year I have my outlet installed and burning rods! Pictures to follow soon if I can figure how to do it from my phone. Basic info, its an ac National Welder with settings from 30 to 220(I think). First practice was 1/8 6011 at 75 amps on some 3/16 angle. Then I tried some 1/16 6013 on a lawn mower blade at about 40 .

welding 20 gauge sheet metal

mig welding thin metal videos

CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or Computer Aided Design (CAD) software like .

welding thin sheet metal with stick rods|mig welding thin metal videos