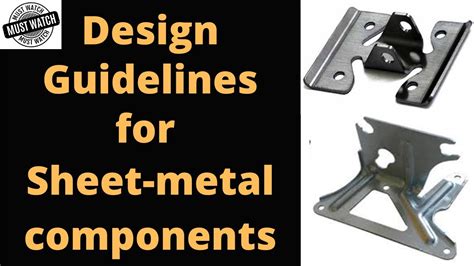

dfm for sheet metal DFM Guidebook is a reference handbook covering design for manufacturing guidelines for sheet metal, machining, casting, injection molding, additive manufacturing and assembly

It also prevents the cable from rubbing against the edge of the box and .

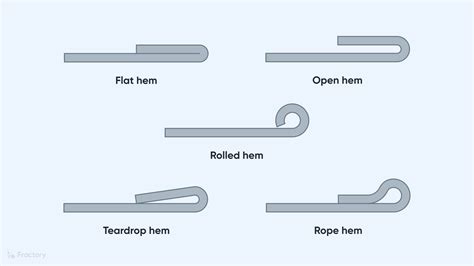

0 · sheet metal hem design guide

1 · sheet metal gusset design guidelines

2 · sheet metal guidelines pdf

3 · sheet metal drawing for practice

4 · sheet metal dimensioning guidelines

5 · sheet metal dfm guidelines

6 · sheet metal bracket design guidelines

7 · hole to distance sheet metal

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information.

DFMPro for Sheet metal provides sheet metal design guidelines and DFM best practices to produce better quality designs at lower manufacturing costs.DFM Guidebook is a reference handbook covering design for manufacturing .Few simple yet integral tips which need to be taken into consideration while .In this article, we’ll be taking a deep dive into sheet metal DFM. Starting with the 2D cutting process needed to make a blank, then exploring forming operations necessary for various sheet metal features, and finally concluding with .

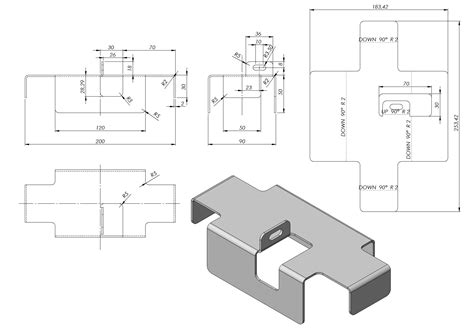

Our automated sheet metal design for manufacturability (DFM) feedback highlights specific features in your part design that can be optimized for the fabrication process. DFM helps to .DFM Guidebook is a reference handbook covering design for manufacturing guidelines for sheet metal, machining, casting, injection molding, additive manufacturing and assemblyFew simple yet integral tips which need to be taken into consideration while designing a sheet metal part. Get insights into real shop floor issues which can be side-stepped by correctly designing sheet metal parts. To avoid workpiece failure, DFM guidelines recommend a minimum distance (D1) from hole to the sheet edge equal to at least the plate thickness (T); we recommend a safe design zone of 1.5 to 2T. Also, when piercing multiple .

Design for Manufacturability (DFM) is a strategic approach that integrates manufacturing considerations into the design process, ensuring that products are easier and . Prioritize material selection and geometric considerations for efficient sheet metal fabrication. Embrace DFM principles to minimize costs and enhance product quality in manufacturing. Implement design guidelines and . Sheet metal design for manufacturability (DFM) is a strategic approach to part design that aligns with the intricacies of the fabrication process. In doing so, metal manufacturers can optimize efficiency, curtail production .

9 Design for Manufacturing Considerations for Sheet Metal Fabrication. When engineers understand DFM best practices, they set themselves up for success by ensuring that manufacturing can occur as .DFMPro for Sheet metal provides sheet metal design guidelines and DFM best practices to produce better quality designs at lower manufacturing costs.In this article, we’ll be taking a deep dive into sheet metal DFM. Starting with the 2D cutting process needed to make a blank, then exploring forming operations necessary for various sheet metal features, and finally concluding with finishing and assembly considerations as well as how to ensure your team puts out good designs that your .

Our automated sheet metal design for manufacturability (DFM) feedback highlights specific features in your part design that can be optimized for the fabrication process. DFM helps to identify design situations such as: When features (holes, cutouts, notches) are close to a bend, resulting in possible feature deformation. .DFM Guidebook is a reference handbook covering design for manufacturing guidelines for sheet metal, machining, casting, injection molding, additive manufacturing and assemblyFew simple yet integral tips which need to be taken into consideration while designing a sheet metal part. Get insights into real shop floor issues which can be side-stepped by correctly designing sheet metal parts. To avoid workpiece failure, DFM guidelines recommend a minimum distance (D1) from hole to the sheet edge equal to at least the plate thickness (T); we recommend a safe design zone of 1.5 to 2T. Also, when piercing multiple holes, we recommend a spacing between holes (D2) greater than 2T.

sheet metal hem design guide

Design for Manufacturability (DFM) is a strategic approach that integrates manufacturing considerations into the design process, ensuring that products are easier and more cost-effective to produce. When working with sheet metal, DFM is essential, especially when creating complex forms. Prioritize material selection and geometric considerations for efficient sheet metal fabrication. Embrace DFM principles to minimize costs and enhance product quality in manufacturing. Implement design guidelines and tolerance specifications tailored for . Sheet metal design for manufacturability (DFM) is a strategic approach to part design that aligns with the intricacies of the fabrication process. In doing so, metal manufacturers can optimize efficiency, curtail production costs, and elevate the quality of the end product. 9 Design for Manufacturing Considerations for Sheet Metal Fabrication. When engineers understand DFM best practices, they set themselves up for success by ensuring that manufacturing can occur as seamlessly as possible. Designs that are easily manufacturable are associated with shorter lead times and lower prices.

DFMPro for Sheet metal provides sheet metal design guidelines and DFM best practices to produce better quality designs at lower manufacturing costs.

In this article, we’ll be taking a deep dive into sheet metal DFM. Starting with the 2D cutting process needed to make a blank, then exploring forming operations necessary for various sheet metal features, and finally concluding with finishing and assembly considerations as well as how to ensure your team puts out good designs that your .

Our automated sheet metal design for manufacturability (DFM) feedback highlights specific features in your part design that can be optimized for the fabrication process. DFM helps to identify design situations such as: When features (holes, cutouts, notches) are close to a bend, resulting in possible feature deformation. .DFM Guidebook is a reference handbook covering design for manufacturing guidelines for sheet metal, machining, casting, injection molding, additive manufacturing and assembly

Few simple yet integral tips which need to be taken into consideration while designing a sheet metal part. Get insights into real shop floor issues which can be side-stepped by correctly designing sheet metal parts. To avoid workpiece failure, DFM guidelines recommend a minimum distance (D1) from hole to the sheet edge equal to at least the plate thickness (T); we recommend a safe design zone of 1.5 to 2T. Also, when piercing multiple holes, we recommend a spacing between holes (D2) greater than 2T.

Design for Manufacturability (DFM) is a strategic approach that integrates manufacturing considerations into the design process, ensuring that products are easier and more cost-effective to produce. When working with sheet metal, DFM is essential, especially when creating complex forms.

Prioritize material selection and geometric considerations for efficient sheet metal fabrication. Embrace DFM principles to minimize costs and enhance product quality in manufacturing. Implement design guidelines and tolerance specifications tailored for .

Sheet metal design for manufacturability (DFM) is a strategic approach to part design that aligns with the intricacies of the fabrication process. In doing so, metal manufacturers can optimize efficiency, curtail production costs, and elevate the quality of the end product.

stainless steel cabinets and countertops

sheet metal gusset design guidelines

These are the most common types of plumbing piping materials found in homes of different ages, what they are used for, and an overview of how to cut and fasten them together. Here are types of plumbing materials used in piping for waste lines, water supply pipes, and natural gas supply:

dfm for sheet metal|sheet metal drawing for practice