cnc machine accident In this blog post, we will delve into the world of CNC machine crashes, exploring their causes, the risks involved, and the measures that can be taken to prevent them. Let us uncover the . As pictured to bookends each weighing 2 lbs. 12 oz., these are metal, I believe it to be copper as it is visible through some of the scuffs on the body of the lions and the base but could be brass. Fo.from

0 · worst cnc machine crash

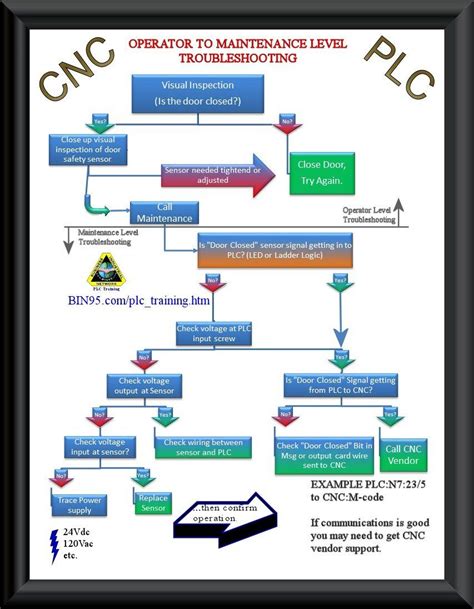

1 · cnc troubleshooting guide

2 · cnc online crashing

3 · cnc machine troubleshooting

4 · cnc machine tool crashes

5 · cnc machine problems and solutions

6 · cnc machine fails

7 · cnc machine crash report

The best fabric paint depends on the type of fabric you plan to use in your project. Do you want a long-lasting throw pillow or a simple seasonal craft? Below are Waller's three go-to.

In this blog post, we will delve into the world of CNC machine crashes, exploring their causes, the risks involved, and the measures that can be taken to prevent them. Let us uncover the .

Top 10 Dangerous CNC Crash Fail Compilation. Top 10 Dangerous CNC Crash Fail Compilation.By understanding the causes and consequences of CNC milling machine crashes, as well as implementing preventive measures and adhering to best practices for safety, manufacturers . Machining and metalworking shops can be dangerous places to work, with a wide variety of potential accidents waiting for workers who are unaware, unalert, or unprepared. From chemical spills and fires to severe . CNC machine crashes are relatively easy to avoid. They often occur during setup and debugging. If you can recognize high-risk situations, you’ll be in a better position to avoid them.

One of the most common dangers of CNC machining is being struck by flying parts. And trust me, this happens more often than you might think since chips and fragments can be ejected at high velocities during the . This case involves a machinist who suffered serious injuries when operating a CNC machine. The woman was operating a CNC metal lathe at the time of the incident in accordance with safety guidelines and commonly .

Preventing CNC machine crashes starts with proper setup and programming—double-checking tool paths, speeds, and fixture positions is crucial. Regular maintenance, including checking for. Learn about the potential hazards of CNC machines, their safety features, and guidelines that will enable you to safely work with these machines, preventing accidents in the workplace. 1. Noise. 2. Chips. 3. Moving Components or Machinery. 4. Falling Heavy Objects. 5. Heat from the Cutting Process. 1. Safety or Containment Shield. 2. Video Cameras.

In this blog post, we will delve into the world of CNC machine crashes, exploring their causes, the risks involved, and the measures that can be taken to prevent them. Let us uncover the implications of these incidents and shed light on the significance of safety protocols in CNC machine operations.

Top 10 Dangerous CNC Crash Fail Compilation. Top 10 Dangerous CNC Crash Fail Compilation. Even with modern protection features, CNC machines can still pose a hazard to workers. Here are 5 critical safety tips to help keep operators out of danger. Using powerful equipment safely is essential for preventing workplace injuries.By understanding the causes and consequences of CNC milling machine crashes, as well as implementing preventive measures and adhering to best practices for safety, manufacturers can ensure a smooth and accident-free milling process.

Machining and metalworking shops can be dangerous places to work, with a wide variety of potential accidents waiting for workers who are unaware, unalert, or unprepared. From chemical spills and fires to severe lacerations and even possible amputations, the . CNC machine crashes are relatively easy to avoid. They often occur during setup and debugging. If you can recognize high-risk situations, you’ll be in a better position to avoid them. One of the most common dangers of CNC machining is being struck by flying parts. And trust me, this happens more often than you might think since chips and fragments can be ejected at high velocities during the machining process. This case involves a machinist who suffered serious injuries when operating a CNC machine. The woman was operating a CNC metal lathe at the time of the incident in accordance with safety guidelines and commonly accepted best practices.

Preventing CNC machine crashes starts with proper setup and programming—double-checking tool paths, speeds, and fixture positions is crucial. Regular maintenance, including checking for. Learn about the potential hazards of CNC machines, their safety features, and guidelines that will enable you to safely work with these machines, preventing accidents in the workplace. 1. Noise. 2. Chips. 3. Moving Components or Machinery. 4. Falling Heavy Objects. 5. Heat from the Cutting Process. 1. Safety or Containment Shield. 2. Video Cameras.In this blog post, we will delve into the world of CNC machine crashes, exploring their causes, the risks involved, and the measures that can be taken to prevent them. Let us uncover the implications of these incidents and shed light on the significance of safety protocols in CNC machine operations.Top 10 Dangerous CNC Crash Fail Compilation. Top 10 Dangerous CNC Crash Fail Compilation.

Even with modern protection features, CNC machines can still pose a hazard to workers. Here are 5 critical safety tips to help keep operators out of danger. Using powerful equipment safely is essential for preventing workplace injuries.By understanding the causes and consequences of CNC milling machine crashes, as well as implementing preventive measures and adhering to best practices for safety, manufacturers can ensure a smooth and accident-free milling process.

Machining and metalworking shops can be dangerous places to work, with a wide variety of potential accidents waiting for workers who are unaware, unalert, or unprepared. From chemical spills and fires to severe lacerations and even possible amputations, the . CNC machine crashes are relatively easy to avoid. They often occur during setup and debugging. If you can recognize high-risk situations, you’ll be in a better position to avoid them. One of the most common dangers of CNC machining is being struck by flying parts. And trust me, this happens more often than you might think since chips and fragments can be ejected at high velocities during the machining process. This case involves a machinist who suffered serious injuries when operating a CNC machine. The woman was operating a CNC metal lathe at the time of the incident in accordance with safety guidelines and commonly accepted best practices.

worst cnc machine crash

white metal curtain brackets

What is junction box schedule? A junction box schedule is a document or a table that lists all the junction boxes installed in a building or a construction project.

cnc machine accident|cnc machine troubleshooting