cnc machines construction CNC machining is a manufacturing process that utilizes computer-controlled devices to perform complex tasks with precision. The process follows instructions from a software file, typically a Computer-Aided Design (CAD) file, . Custom Metal Solutions. As an experienced OEM manufacturer more than 20 years, Aibet helps customers from diverse industries with manufacture & machining of metal components.

0 · structure of cnc machine tools

1 · how cnc machine is controlled

2 · explain mcu in cnc

3 · cnc machine working principle

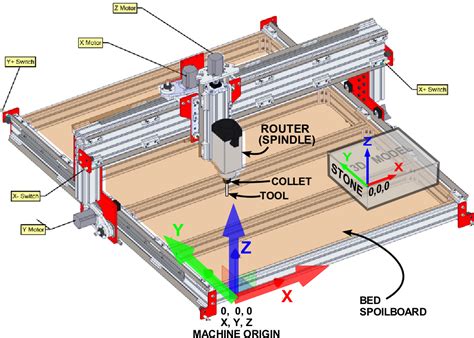

4 · cnc machine parts diagram

5 · cnc machine block diagram

6 · cnc lathe machine working principle

7 · cnc full form in construction

Precision CNC machined parts made from turned or milled plastic and metal components. We offer the wide range of CNC machining parts and we are open to manufacturing custom CNC machining parts as per your unique requirements. CNC machining services feature personalized customer service for made-to-order parts and components.

CNC machining is a manufacturing process that utilizes computer-controlled devices to perform complex tasks with precision. The process follows instructions from a software file, typically a Computer-Aided Design (CAD) file, .

In today’s fast-paced world of construction, Computer Numerical Control (CNC) technology plays a pivotal role in streamlining and optimizing the manufacturing of building . CNC machines have instilled unprecedented precision and efficiency in the industry, marking a new era in construction. Their advanced technology enables builders to work with high accuracy, mitigating the risk of .

CNC milling is revolutionizing the construction industry by offering precision, speed, and versatility that traditional methods can’t match. Whether it’s shaping complex .

Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC . Computer Numerical Control (CNC) machining is a manufacturing process that utilizes computer-controlled machines to produce precise and intricate parts. These machines follow programmed instructions to manipulate .Explore how fabrication technology is transforming the construction industry, focusing on efficiency, quality control, and sustainability through off-site manufacturing and modular .

5K+Quality industrial CNC machines made to revolutionize the construction industry. Build a Higher ROI. When it comes to CNC in the construction industry, Amera-Seiki emerges as a .CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or .Check out our articles, news and reviews covering all aspects of CNC Machines, including CNC mills, lathes, top brands, materials, and precision engineering. Rapid Results AI. Login / Signup. CNC Machines (1441) CNC Mill . Explore how fabrication technology is transforming the construction industry, focusing on efficiency, quality control .

CNC Machines (1442) CNC Mill (798) CNC Lathe (498) Vertical Machining Center (646) Horizontal Machining Center (139) Boring Mill (13) Router (106) EDM (21) . In the construction industry, CNC machining is used to create custom metal structures, HVAC components, and framing systems. Case Study: Turner Construction .Because of CNC machines, we have less expensive goods, stronger national defense and a higher standard of living than is possible in a non-industrialized world. In this article, we’ll explore the origins of the CNC machine, different .

structure of cnc machine tools

These machines are commonly used in industries such as aerospace, automotive, and construction. Grinding CNC Machines. Grinding CNC machines are designed for precision grinding and polishing tasks. They utilize abrasive wheels or discs to remove material from the workpiece, resulting in a smooth and polished surface. These machines are commonly . The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation of CNC machines using G and M codes to control axes movement, feed rates, spindle speeds, tool changes, and other functions. According to number of axes: 4 & 5 axes CNC machines 4 and 5 axes CNC machines provide multi-axis machining capabilities beyond the standard 3-axis CNC tool path movements. A 5-axis milling centre includes the three X, Y, Z axes, the A axis which is rotary tilting of the spindle and the B- axis, which can be a rotary index table.. We have listed top 10 best CNC machine manufacturers & brands including Mazak, Trumpf, DMG MORI, MAG, Haas, Hardinge, AMADA, Okuma, Makino, EMAG in the world . high-torque brushless servo motors in each axis, and robust casting construction. A wide range of machine configurations are available: 40- and 50-taper gear-driven models for high .

metal lockout box

These tips for Standard CNC machine assembly are applicable for machines purchased prior to September 2017. . The Z-axis is one of the more intimidating aspects of machine construction to most people, but it's not terribly difficult. Follow the steps below to assemble your z. The Role of CNC Machining in the Construction Equipment Industry In the ever-evolving world of manufacturing, Computer Numerical Control (CNC) machining has emerged as a revolutionary technology. CNC machining involves the use of computers to control machine tools, such as lathes, mills, routers, and grinders. The precision and automation offered by .

What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials.; Types of CNC machines: There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.Each machine has its own advantages and .

metal lock box for thermostat

how cnc machine is controlled

At WayKen, we always understand the importance of quality control in CNC machining. Our comprehensive CNC machining services offer advanced technologies to ensure high-quality products. We also utilize a series of inspection tools and methods, including Coordinate Measuring Machines (CMM), traditional calipers and micrometers, surface finish . A CNC machine tool always has a sliding table and a spindle to control the position and speed. The table of the machine is controlled in the X and Y-axis direction and the spindle is controlled in the Z-axis direction. Driving System. The driving system of a CNC machine includes an amplifier circuit, drive motors, and ball lead screws. Types of CNC Machines: • CNC Lathe machines • CNC Milling machines • CNC Grinding machines. CNC Lathe Machines: • Automated version of a manual lathe. • Programmed to change tools automatically. • Used for turning and boring wood, metal and plastic. CNC Milling Machines • Has 3 to 5 axes. • Used for wood, metal and plastic.

CNC machines include lathes, routers, and grinders, milling machines, plasma cutters, and EDM machines. 3D printers are also a type of CNC machine. You control CNC machines with CAD CAM software, which takes a 3D design and turns it into g-code, which are the instructions for where the CNC machine should move and cut the part. Control Software

Top 10 CNC Machine Brands and Their Flagship Models. CNC (Computer Numerical Control) machines are integral to modern manufacturing, enabling precision and efficiency across various industries. . Series vertical machining centers are designed for efficiency and productivity, featuring advanced controls and robust construction. Their ability . THe advantages of CNC Machines include: Unmatched Accuracy and Precision: CNC machines excel in producing jobs with the highest level of accuracy and precision, surpassing any manual machine's capabilities. .While the integration of CNC machines in construction brings forth numerous advantages, it is crucial to address the challenges and considerations associated with this transformative technology. 4.1 Initial Investment: The acquisition and .

With CNC machines, architecture can explore various potentials and CNC technology is already being used for many architectural purposes today. Design Ideas for the Built World. . With the implementation of CNC technology, the construction industry will be able to reduce labor costs, and unskilled people will be able to much more easily create .

Hurco is known worldwide for our control software, and for conversational or “shop floor” programming, but we don’t often get enough credit for the machine’s. Learning CNC machining can be challenging at first, but it becomes easier with practice. Several factors determine the complexity of learning CNC machining, including the type of CNC machine, the software used, and the learner’s technical background.. Technical Knowledge: A solid understanding of basic mechanical and electrical principles is beneficial .

Prepare for a career as a computer numerical control (CNC) machinist, CNC machine operator, CNC lathe operator, CNC mill operator, CNC operator, machine operator, or machinist; . Fixture Body Construction 200; Fixture Design Basics 210; Drill Bushing Selection 230; Math Math Fundamentals 101; Math: Fractions and Decimals 111;The Amada AP3-2510V is a sophisticated CNC punch press designed for precise sheet metal fabrication. Known for its reliability and efficiency, the AP3-2510V serves industries ranging from automotive to aerospace. Its capabilities extend to forming intricate parts with materials such as aluminum and mild steel. Businesses benefit from its user-friendly interface and robust .Haas Automation is the largest machine tool builder in the western world, manufacturing a complete line of CNC vertical machining centers, horizontal machining centers, CNC lathes, and rotary products. The cost of CNC machines is influenced by several key factors, each playing a significant role in determining the final price. Understanding these determinants is crucial for anyone looking to invest in CNC technology. . For instance, if you are in the market for a CNC machine specifically designed for trailer construction and roof racks .

explain mcu in cnc

CNC plasma cutting machines are commonly used in metal fabrication, construction, and automotive industries. Waterjet Cutters Waterjet cutters utilize highly pressurized water jets focused through a jewel orifice to cut through various materials.The Langmuir Crossfire Pro CNC machine is a vital tool for industries including but not limited to automotive, aerospace, and manufacturing. Known for its ability to work with various materials, it is utilized for creating intricate parts and components. . Robust construction for durability; Langmuir Crossfire Pro Cons. Requires space for .

Computer numerical control (CNC) is the automation of machine tools by means of computers executing pre-programmed sequences of machine control commands. This is in contrast to machines that are manually controlled by hand wheels or levers, or mechanically automated by cams alone.

Cnc Titanium Parts Manufacturers, Factory, Suppliers From China, Through more than 8 years of business, we have accumulated rich experience and advanced technologies in the production of our products.

cnc machines construction|structure of cnc machine tools