aluminum sheet metal bend radius The bend radius refers to the inner radius of curvature in a bent metal part, where ‘t’ represents the material thickness. This parameter is crucial in sheet metal fabrication and structural design. Metal Fabricators of Zambia Plc (ZAMEFA) manufactures and markets copper rods and copper and aluminium electrical conductors in Zambia and for international export.

0 · sheet metal minimum bend length

1 · sheet metal inside bend radius

2 · sheet metal bend radius standard

3 · sheet metal bend radius guide

4 · radius of regular 90 bend

5 · bending steel plate minimum radius

6 · 6061 sheet metal bend radius

7 · 5052 aluminum minimum bend radius

Our main product line includes CNC electric tube bending machines, CNC electric R&L tube bending machines, CNC hybrid tube bending machines, end-forming machines, and 6-axis vertical articulated mechanical arms. We manufacture approximately 200 tube bender machines in .

sheet metal minimum bend length

Check out the reference tables for steel and aluminium below to find out which bend radius is the most suitable for your sheet metal bending projects.RECOMMENDED MINIMUM BEND RADII FOR 90-DEGREE COLD FORMING OF SHEET The radii listed are the minimum recommended for bending sheets and plates without fracturing in . Similar to low carbon steel, the minimum bend radius for aluminum alloys is typically equal to the sheet thickness. However, some specific alloys can exhibit better or worse formability. Here’s a general guide to minimum bend .

The bend radius refers to the inner radius of curvature in a bent metal part, where ‘t’ represents the material thickness. This parameter is crucial in sheet metal fabrication and structural design.

sheet metal inside bend radius

sheet metal bend radius standard

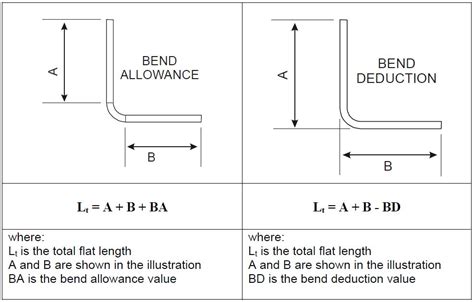

K-factor, bend allowance/deduction, and outside setbacks all affect sheet metal design. Learn about them to avoid issues during your design process.Follow this quick checklist to ensure high tolerance bent parts. Each of these will be elaborated on below. All Parts are bent with a .030" bend Radius. Use the chat bubble if you have any . We recommend a minimum bend radius of 1t for all sheet metal parts. Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet. For example, if the thickness of the sheet is 1 mm, .

This free chart outlines what bend radii is required for the approximate thickness of aluminum. We recommend printing it out to keep as a reference. Minimum permissible radius varies with nature of forming operation, .

The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by Protocase. We go beyond the general rules of sheet metal bending, as our .It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. Use this document to choose values that are both manufacturable and meet your needs. Check out the reference tables for steel and aluminium below to find out which bend radius is the most suitable for your sheet metal bending projects.

RECOMMENDED MINIMUM BEND RADII FOR 90-DEGREE COLD FORMING OF SHEET The radii listed are the minimum recommended for bending sheets and plates without fracturing in a standard press brake with air bend dies. Other types of bending operations may require larger radii or permit smaller radii. Similar to low carbon steel, the minimum bend radius for aluminum alloys is typically equal to the sheet thickness. However, some specific alloys can exhibit better or worse formability. Here’s a general guide to minimum bend radii for a few popular aluminum alloys:

best cnc machine manufacturers in the world

The bend radius refers to the inner radius of curvature in a bent metal part, where ‘t’ represents the material thickness. This parameter is crucial in sheet metal fabrication and structural design.

K-factor, bend allowance/deduction, and outside setbacks all affect sheet metal design. Learn about them to avoid issues during your design process.Follow this quick checklist to ensure high tolerance bent parts. Each of these will be elaborated on below. All Parts are bent with a .030" bend Radius. Use the chat bubble if you have any questions about our process. See a full list of all bending materials and their capabilities. We recommend a minimum bend radius of 1t for all sheet metal parts. Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet. For example, if the thickness of the sheet is 1 mm, the minimum bend radius should be 1 mm. This free chart outlines what bend radii is required for the approximate thickness of aluminum. We recommend printing it out to keep as a reference. Minimum permissible radius varies with nature of forming operation, type of forming equipment and .

The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by Protocase. We go beyond the general rules of sheet metal bending, as our customers want tight bend radii for sheet metal parts. It is possible to choose other bends if you require, but additional lead time and tooling charges may apply.It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. Use this document to choose values that are both manufacturable and meet your needs.

Check out the reference tables for steel and aluminium below to find out which bend radius is the most suitable for your sheet metal bending projects.RECOMMENDED MINIMUM BEND RADII FOR 90-DEGREE COLD FORMING OF SHEET The radii listed are the minimum recommended for bending sheets and plates without fracturing in a standard press brake with air bend dies. Other types of bending operations may require larger radii or permit smaller radii. Similar to low carbon steel, the minimum bend radius for aluminum alloys is typically equal to the sheet thickness. However, some specific alloys can exhibit better or worse formability. Here’s a general guide to minimum bend radii for a few popular aluminum alloys:

The bend radius refers to the inner radius of curvature in a bent metal part, where ‘t’ represents the material thickness. This parameter is crucial in sheet metal fabrication and structural design.

K-factor, bend allowance/deduction, and outside setbacks all affect sheet metal design. Learn about them to avoid issues during your design process.

Follow this quick checklist to ensure high tolerance bent parts. Each of these will be elaborated on below. All Parts are bent with a .030" bend Radius. Use the chat bubble if you have any questions about our process. See a full list of all bending materials and their capabilities. We recommend a minimum bend radius of 1t for all sheet metal parts. Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet. For example, if the thickness of the sheet is 1 mm, the minimum bend radius should be 1 mm.

This free chart outlines what bend radii is required for the approximate thickness of aluminum. We recommend printing it out to keep as a reference. Minimum permissible radius varies with nature of forming operation, type of forming equipment and .

sheet metal bend radius guide

About Zenda Heating & Sheet Metal; Resources/Articles. Bryant Social Crew; Service Areas; Reviews; Image Gallery; Careers; Heating & Cooling. Heating. Heating Installation; Heating Repair; . Heat pumps are more efficient than ever. Watch this video to learn about the benefits of Bryant’s Evolution Extreme heat pump! #BryantPromo. Read More.

aluminum sheet metal bend radius|6061 sheet metal bend radius