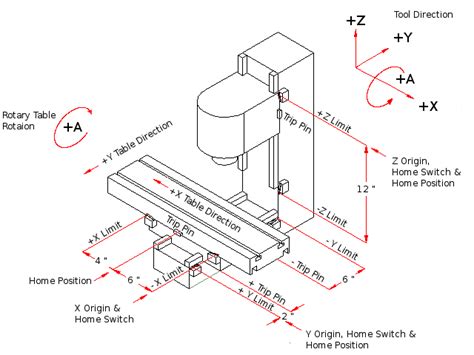

14 axis cnc machine A 5-axis CNC machine has a CNC machine axis count of 5. This number includes the three main linear axes (X, Y, and Z) and any two rotary axes. This means that a 5-axis . See more Telecommunication enclosures are fully assembled or modular field-assembled transportable structures capable of housing an electronic communications system. These enclosures provide a controlled internal environment for the communications . See more

0 · multi axis cnc machines

1 · mill xyz axis

2 · hobby 4 axis cnc machine

3 · cnc axis explained

4 · axis identification in cnc machine

5 · 4 axis hobby cnc

6 · 12 axis cnc mill

7 · 12 axis cnc machine price

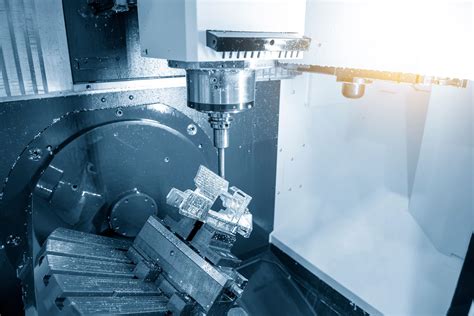

CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or Computer Aided Design (CAD) software like .

multi axis cnc machines

As the name suggests, the 2-axis CNC machine has moving components that travel along two axes. Depending on the type of machine and the work envelope’s orientation (i.e., . See moreThe 3-axis CNC machine configuration is primarily found in CNC milling machines. In these machines, the workpiece is held in place by a vise. The vise, in turn, is fixed to a moving table. . See more

A 5-axis CNC machine has a CNC machine axis count of 5. This number includes the three main linear axes (X, Y, and Z) and any two rotary axes. This means that a 5-axis . See more

blue metal truck box

In 4-axis CNC machines, the axis count is 4. Such machines have the capabilities of a 3-axis machine, i.e., their cutting tool and/or table can move along the X, Y, and Z axes. However, . See moreServo- driven axes and spindle motor, motion on linear rails along with a frame constructed from epoxy granite mean higher precision, smoother operation, and enhanced durability. Additionally, Tormach allows users to add accessories .Haas TM Series Toolroom Mills are affordable 40-taper mills that offer the full power and functionality of the easy-to-use Haas CNC control, including available 4th- and 5th-axis .In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis .

Here's how 5-axis CNC machines are transforming manufacturing: 1. What is 5-Axis CNC Machining? Unlike traditional 3-axis systems, 5-axis machines move a part or tool along .Multi-axis CNC machining is a manufacturing process in which a cutting tool that can move in three or more directions is controlled by a computer. The precise CNC technology and multiple .

The top 10 CNC machine brands, each with their flagship models, offer various options to suit different applications and budgets. By understanding the strengths of these brands and their . Learn about CNC machine axis counts, including the types of axes and how they are incorporated in the creation of 2-axis, 3-axis, 4-axis, and 5-axis CNC systems.

Servo- driven axes and spindle motor, motion on linear rails along with a frame constructed from epoxy granite mean higher precision, smoother operation, and enhanced durability. Additionally, Tormach allows users to add accessories over time so .Haas TM Series Toolroom Mills are affordable 40-taper mills that offer the full power and functionality of the easy-to-use Haas CNC control, including available 4th- and 5th-axis capability. Very easy to learn and operate, they are perfect for schools, companies transitioning to CNC, or anyone looking for a large-travel machine on a budget.In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes. Here's how 5-axis CNC machines are transforming manufacturing: 1. What is 5-Axis CNC Machining? Unlike traditional 3-axis systems, 5-axis machines move a part or tool along three linear axes (X, Y, Z) while rotating it along two additional axes (A, B). This capability allows manufacturers to approach the workpiece from virtually any angle .

Multi-axis CNC machining is a manufacturing process in which a cutting tool that can move in three or more directions is controlled by a computer. The precise CNC technology and multiple angles of these machines allows for the manufacture of high-quality and complex custom components that can withstand rigorous environments. Custom components .The top 10 CNC machine brands, each with their flagship models, offer various options to suit different applications and budgets. By understanding the strengths of these brands and their machines, manufacturers can make informed decisions that enhance their production capabilities.

Dual-axis spindle head provides ±245 degrees of C-axis rotation and ±120 degrees of B-axis tilt; 5-axis simultaneous machining; Powerful brakes on the B and C axes for rigid 3+2 machining; HSK-A63 taper; Includes Tool Center Point Control

Four axes on a CNC machine add an extra cutting direction, which increases precision. The fifth axis further improves the accuracy of the machine, but the cost of the five-axis CNC machine makes it too expensive for most businesses.

CNC machines are typically divided into these five groups: The axes determine the machine’s abilities, including how it moves, how it cuts into the workpiece, and whether or not it maneuvers the material or cutting tool to create the finished product. Learn about CNC machine axis counts, including the types of axes and how they are incorporated in the creation of 2-axis, 3-axis, 4-axis, and 5-axis CNC systems.Servo- driven axes and spindle motor, motion on linear rails along with a frame constructed from epoxy granite mean higher precision, smoother operation, and enhanced durability. Additionally, Tormach allows users to add accessories over time so .Haas TM Series Toolroom Mills are affordable 40-taper mills that offer the full power and functionality of the easy-to-use Haas CNC control, including available 4th- and 5th-axis capability. Very easy to learn and operate, they are perfect for schools, companies transitioning to CNC, or anyone looking for a large-travel machine on a budget.

In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes. Here's how 5-axis CNC machines are transforming manufacturing: 1. What is 5-Axis CNC Machining? Unlike traditional 3-axis systems, 5-axis machines move a part or tool along three linear axes (X, Y, Z) while rotating it along two additional axes (A, B). This capability allows manufacturers to approach the workpiece from virtually any angle .Multi-axis CNC machining is a manufacturing process in which a cutting tool that can move in three or more directions is controlled by a computer. The precise CNC technology and multiple angles of these machines allows for the manufacture of high-quality and complex custom components that can withstand rigorous environments. Custom components .

The top 10 CNC machine brands, each with their flagship models, offer various options to suit different applications and budgets. By understanding the strengths of these brands and their machines, manufacturers can make informed decisions that enhance their production capabilities.Dual-axis spindle head provides ±245 degrees of C-axis rotation and ±120 degrees of B-axis tilt; 5-axis simultaneous machining; Powerful brakes on the B and C axes for rigid 3+2 machining; HSK-A63 taper; Includes Tool Center Point Control

Four axes on a CNC machine add an extra cutting direction, which increases precision. The fifth axis further improves the accuracy of the machine, but the cost of the five-axis CNC machine makes it too expensive for most businesses.

bnc video distribution box

A subpanel breaker box manages and supplies electricity to specific areas of a property. Also called a satellite breaker panel, it often has fewer circuit breakers than a main electric panel. Since it often controls and provides electrical currents to a specific area, a subpanel looks like a smaller version of the main circuit breaker box.

14 axis cnc machine|mill xyz axis