cold rolling process sheet metal The earliest rolling mills in crude form but the same basic principles were found in Middle East and South Asia as early as 600 BCE. The invention of the rolling mill in Europe may be attributed to Leonardo da Vinci in his drawings. Earliest rolling mills were See more

Sheet metal is one of the shapes and forms metal can be bought in. Sheet metal is any metal that has a thickness in between 0.5.6 millimetres. There are other measurement units used to categorise metals by thickness, .

0 · cold rolled steel sheet specification

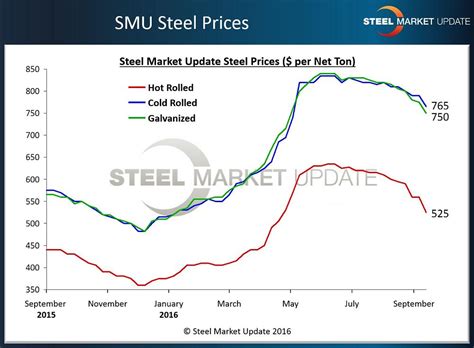

1 · cold rolled steel price today

2 · cold rolled steel plate specifications

3 · 4x8 18 gauge sheet metal

4 · 24 gauge sheet metal 4x8

5 · 1mm cold rolled steel sheet

6 · 14 gauge 4x8 sheet metal

7 · 1045 cold rolled steel plate

Sheet metal can be made of a variety of materials, including copper, aluminum, steel and titanium. There are four basic stages in the process of making sheet metal: melting, pouring, pickling and lastly, rolling and annealing.

If the temperature of the metal is below its recrystallization temperature, the process is known as cold rolling. In terms of usage, hot rolling processes more tonnage than any other manufacturing process, and cold rolling processes the most tonnage out of all cold working processes. See moreIn metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical . See moreRolling mills for lead seem to have existed by the late 17th century. Copper and brass were also rolled by the late 18th century. See moreUntil well into the eighteenth century, rolling mills derived their power from water wheels. The first recorded use of a steam engine directly driving a mill is attributed to John Wilkinson's Bradley Works where, in 1786, a Boulton and Watt engine was coupled to a slitting . See more

cold rolled steel sheet specification

cold rolled steel price today

Roll bendingRoll bending produces a cylindrical shaped product from plate or steel metals.Roll forming See moreThe earliest rolling mills in crude form but the same basic principles were found in Middle East and South Asia as early as 600 BCE. The invention of the rolling mill in Europe may be attributed to Leonardo da Vinci in his drawings. Earliest rolling mills were See moreHot rollingHot rolling is a metalworking process that occurs above the recrystallization temperature of the material. After the grains deform during processing, they recrystallize, which maintains an equiaxed microstructure See more

A rolling mill, also known as a reduction mill or mill, has a common construction independent of the specific type of rolling being performed: See more

Cold rolling refers to reducing the thickness of metal sheets or strips by passing them through a pair of rolls at room temperature. This method contrasts with hot rolling, where metals are . The process of cold rolling a metal alloy starts with either sheet metal or strip coil. These materials are placed into large rollers, which compress it down and squeeze it under high pressure just below its ultimate tensile strength. Learn how this essential metalworking technique enhances the strength, hardness, and surface finish of steel. We cover each step of the process, from pickling to annealing, and discuss the benefits.

sheet metal contractors miami

cold rolled steel plate specifications

sheet metal code book

The cold rolling process has the advantage of providing close dimensional tolerance up to 0.025 mm. It also improves toughness, hardness, mechanical strength, surface finish of the material. Softer metals like tin, silver, gold, .It begins with comprehensive coverage of rolling processes and the mechanics of rolling, which is the theoretical content of the subject. This is followed by a chapter on ‘rolling practices’ that .Depending on your project, we can process your cold–rolled steel in various finishes, including embossed, perforated, and prepaint. Pacesetter offers three primary steel processing services, which include slitting, blanking/multi . Cold rolling is applied to induce ductility in steel, achieved through annealing of the steel in a process called “the Cold Rolled and Closed Annealed” [12]. A more special process .

If the temperature of the metal is below its recrystallization temperature, the process is known as cold rolling. In terms of usage, hot rolling processes more tonnage than any other manufacturing process, and cold rolling processes the most tonnage out of all cold working processes.

Cold rolling refers to reducing the thickness of metal sheets or strips by passing them through a pair of rolls at room temperature. This method contrasts with hot rolling, where metals are processed at high temperatures.From metallurgical point of view, rolling process can be classified under two broad categories, namely (i) hot rolling and (ii) cold rolling. In hot rolling the material is rolled at a temperature higher than its recrystallization temperature. The advantage of hot rolling is twofold.The process of cold rolling a metal alloy starts with either sheet metal or strip coil. These materials are placed into large rollers, which compress it down and squeeze it under high pressure just below its ultimate tensile strength.

Learn how this essential metalworking technique enhances the strength, hardness, and surface finish of steel. We cover each step of the process, from pickling to annealing, and discuss the benefits.The cold rolling process has the advantage of providing close dimensional tolerance up to 0.025 mm. It also improves toughness, hardness, mechanical strength, surface finish of the material. Softer metals like tin, silver, gold, aluminum and its alloys undergo cold rolling.It begins with comprehensive coverage of rolling processes and the mechanics of rolling, which is the theoretical content of the subject. This is followed by a chapter on ‘rolling practices’ that highlights plant level procedures and practices employed by .

4x8 18 gauge sheet metal

Depending on your project, we can process your cold–rolled steel in various finishes, including embossed, perforated, and prepaint. Pacesetter offers three primary steel processing services, which include slitting, blanking/multi-blanking, and cut-to-length.

Cold rolling is applied to induce ductility in steel, achieved through annealing of the steel in a process called “the Cold Rolled and Closed Annealed” [12]. A more special process of cold rolling is known as skin-rolling and has the least reduction percentage level.

Cold rolling is a process by which the sheet metal or strip stock is introduced between rollers and then compressed and squeezed. This produces sheet stock with good thickness tolerance and surface finish.

If the temperature of the metal is below its recrystallization temperature, the process is known as cold rolling. In terms of usage, hot rolling processes more tonnage than any other manufacturing process, and cold rolling processes the most tonnage out of all cold working processes.Cold rolling refers to reducing the thickness of metal sheets or strips by passing them through a pair of rolls at room temperature. This method contrasts with hot rolling, where metals are processed at high temperatures.From metallurgical point of view, rolling process can be classified under two broad categories, namely (i) hot rolling and (ii) cold rolling. In hot rolling the material is rolled at a temperature higher than its recrystallization temperature. The advantage of hot rolling is twofold.

The process of cold rolling a metal alloy starts with either sheet metal or strip coil. These materials are placed into large rollers, which compress it down and squeeze it under high pressure just below its ultimate tensile strength. Learn how this essential metalworking technique enhances the strength, hardness, and surface finish of steel. We cover each step of the process, from pickling to annealing, and discuss the benefits.

The cold rolling process has the advantage of providing close dimensional tolerance up to 0.025 mm. It also improves toughness, hardness, mechanical strength, surface finish of the material. Softer metals like tin, silver, gold, aluminum and its alloys undergo cold rolling.

sheet metal components list

It begins with comprehensive coverage of rolling processes and the mechanics of rolling, which is the theoretical content of the subject. This is followed by a chapter on ‘rolling practices’ that highlights plant level procedures and practices employed by .Depending on your project, we can process your cold–rolled steel in various finishes, including embossed, perforated, and prepaint. Pacesetter offers three primary steel processing services, which include slitting, blanking/multi-blanking, and cut-to-length.

Cold rolling is applied to induce ductility in steel, achieved through annealing of the steel in a process called “the Cold Rolled and Closed Annealed” [12]. A more special process of cold rolling is known as skin-rolling and has the least reduction percentage level.

APC systems automate the process of exchanging pallets between the machine tool and an external storage system. This enables the machine operator to load and unload parts without interrupting production. APC .

cold rolling process sheet metal|1045 cold rolled steel plate