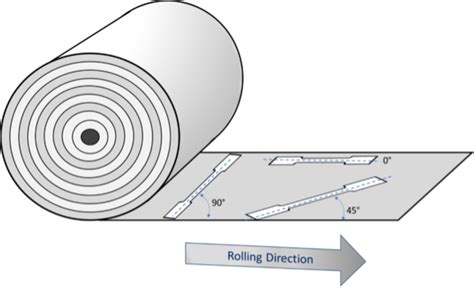

grain direction in sheet metal The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. This is because grain direction makes sheet . Classic look of 32 gauge, galvanized corrugated panels. Perfect for roof and wall applications with a variety of uses, minimum recommended roof slope of 3:12. Resistant to mildew, rot and pests and virtually maintenance free. Environmentally responsible choice containing a up to 30% recycled content and is 100% recyclable

0 · rolling direction of steel plate

1 · rolling direction of sheet metal

2 · minimum flange length sheet metal

3 · metal grain direction diagram

4 · longitudinal vs transverse grain direction

5 · hole to distance sheet metal

6 · grain direction symbol

7 · grain direction in aluminum plate

Many household products such as salt and vinegar effectively kill plants. They can harm plants you want to keep as well as the pesky weeds, so apply them carefully, covering desirable plants with plastic or cardboard to protect them.

Materials with a grain direction that affect the bend angle are considered anisotropic. Materials that don’t have this property are considered isotropic. FIGURE 1. Bends made with the grain (that is, the bend line runs parallel to the grain direction) have a greater .

7. Grain Direction. During the process of turning ingots of metal into sheet at the .

Grain Direction in Metal Bending. When working with plate, pay close attention to .

Learn how the internal structure of metals, such as aluminum, affects their strength and behavior when bending. Find out how to identify and work with the grain direc. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. This is because grain direction makes sheet . 7. Grain Direction. During the process of turning ingots of metal into sheet at the . LT-Long Transverse: perpendicular to direction of principal metal extension. In products whose grain structure clearly shows directionality (width-to-thickness ratio greater than two) it is that perpendicular direction parallel to the .

Grain Direction in Metal Bending. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction (see Figure 1). A plate’s grain direction comes .Grain size and orientation have a significant impact on the performance of sheet metal parts. .

Learn how the grain direction of iron and steel affects the bending process and the risk of fracture. Find out how to avoid cracking by bending perpendicular to the grain and how to improve the grain size with heat treatment. Learn about grain orientation and its impact on forming sheet metal. Find out the implications of bending with or against the grain for crack manifestation.Like a game of Jenga, aligning grain size and direction helps ensure everything fits together .

This has to do with the sheet grain direction. Where Does Grain Direction Come From? The grain direction is in the rolling direction of the sheet as it was being manufactured. Two rollers compressing the hot metal cause the . Applying this to metal bending, be it plate bending, press braking or any other type of metal forming, consideration must be given to the grain direction before any process is carried out. As a general rule, the grain line must run . The direction in which you work with the grain is another important factor in the process. When you’re working with aluminum, for example, it’s vital to know whether you’re working with the grain (longitudinal) or across it . Has anybody heard of bending sheet stock (.063 5052-H32 Aluminum)with grain direction on the diagonal? Local sheet metal shop (not an aircraft shop) experienced cracking on folding up a simple bracket. The bracket is like an upside down 6"long x 4"wide x 2"high box but has integral attaching.

fabrics retain thermal energy better than metals

Sheet metal with an average yield strength of 41,000 PSI can be sold as A36 steel, even though it is 13 percent harder than 36,000-PSI steel. . Bending with, against, or diagonal to the grain direction will produce different bend angles and inside bend radii, all requiring different bend deductions. This adds yet another variable to your . 3.0.3 Why should revision control details be documented in sheet metal fabrication projects? 3.0.4 Why is it important to indicate the grain direction in sheet metal fabrication prints? 3.0.5 How can providing powder coat instructions improve the .

While sheet metal gauges run from 0.005 to 0.249 inch thick, aluminum and steel plate thicknesses start at 0.250 in. and go all the way up to 13 in. or even more. . Grain Direction in Metal Bending. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction (see .

Hi Friends,In this video you will learn Introduction to sheet metal process | Grain direction | Bend allowance & K-factor | Spring backCheck out other videos.

fabtech sheet metal

If you use the sheet metal tools in Solidworks (or most other CAD software), some of the cuts and notches are generated kind of automatically when you bend a side, etc. . Grain direction is included here for Ss304 parts. For the ortho views, we have all the bend dims. (Special care for non-90 degrees, especially overbends) We include a note .Lets you specify sheet metal options. Available for all document types. Options vary depending on whether you are working with a part, assembly, or drawing. . Show grain direction: Displays the grain direction that is defined in the flat pattern feature of the sheet metal part. To view the grain direction, the flat pattern view must include a .When you make anything out of sheet metal, cabinets, enclosures, chassis, housings. you need to think about the grain structure. Talk to GP PRECISION.https.The grain structure of sheet metal gets aligned in the rolling direction during the cold rolling operation. When bending soft materials in the rolling direction cracks may appear. Therefore bending in the direction perpendicular to the rolling direction is always preferred.

Applied To The Surface Of A Sheet Metal Part PTC Creo Share Add a Comment. Sort by: Best. Open comment sort options. Best. Top. New. Controversial. Old. Q&A. Wookie_Magnet • I think it signifies grain direction. Not sure if it has a specific name. Reply reply .The grain direction runs parallel to the rolling direction. For sheet or Panel stock the different directions through the raw material are defined as follows: Figure 4.2.2‑7: Definition of Panel Stock Grain Dire . How to add the Grain or Coil Direction Annotation to a Flat Pattern View for a SolidWorks Sheet Metal Part Drawing. grain direction of sheet metal material . and pre bend strip condition on spring . back on Deep Draw Steel (IS 1079-1994) The effec ts of punch angle, die opening,

rolling direction of steel plate

Introduction to Mechanical Properties. Tensile property characterization of mild and High Strength Low Alloy steel (HSLA) traditionally was tested only in the rolling direction and included only yield strength, tensile strength, and total . The Effect Of Grain Direction In Sheet Metal Bending.For Press tool Design and Other course visit : https://industrylearning.co.in/courses/press-tool-design-nx/

Sheet metal design skills are a crucial tool in any engineer’s toolbox, but given how little attention sheet metal design gets in academia, most skills are learned on the job. . Depending on the exact material, it can sometimes be required to align the grain direction as close to perpedicular with bend lines as possible. Failure to do so .During sheet metal processing ( rolling operation), material grain arranges in the direction of rolling. The material grain rearranges when Sheetmetal is bent perpendicular to the rolling direction. That has a negligible impact on part strength. Inventor needs a feature that can define Material Grain on a sheet metal part to a 3rd party CAM vendor. This would be like an engraved feature on a sheet metal part that can easily identify which way you want the grain direction to be. This can't just be the appearance of material on the part as this is always stripped in translation on 3rd party CAM software. Grain Direction and the Bend Line. The sheet or plate material is the weak link in forming. We should always consider as many material variables as possible before we commit a project for production. . Steve Benson is a member and former chair of the Precision Sheet Metal Technology Council of the Fabricators & Manufacturers Association .

How do i tell the direction of grain. So i cut 14" and bend slowly, hoping i am going against the grain. Do i drill the holes before ot after the bending. Thanks, Jon . F. . I'm aware that metal has a grain structure and it's of extreme importance as it relates to property phase changes during heat treating but, once a metal is in a useable .Since sheet metal is rolled out and cut down into smaller sections, it is possible that the long dimension of a large blank will be the grain direction. Looking at the surface of a piece of metal, any subtle irregularities or lines should indicate the direction of the grain, though a magnifying glass or even a microscope may be needed. 586631 ‘grain direction and fixed face should be options within doc props>sheet metal’- Provide the user with tools>options>doc props>sheet metal options for fixed face and grain direction. These option will be the default on, but the user has the availability to turn them off via RMB>view properties individually Crystal Structure and Rolling Grain Direction: Sheet metal has a specific crystal structure and rolling grain direction. Bending parallel to the grain direction increases the likelihood of fractures due to the alignment of the grains, which can create weak points.

So if you want to change this you can use the Grain Direction, found by editing the Flat Pattern feature, and selecting an edge or sketch line for the Grain Direction (X). The alternative option is: Select the view to rotate. Select the Rotate View icon found in the Heads-Up Toolbar. Enter the value of the rotation angle.

rolling direction of sheet metal

factors affecting sheet metal parts and joint design

How do I size a junction box. Not for pulls, but for conductor fill of 4awg and larger. I'm basically going to be splicing two 4-3 ser cables and will do it in a 6" box but I'd like to know the correct calculation again.

grain direction in sheet metal|metal grain direction diagram