cnc machine cutting fluid We have written this comprehensive guide to help you navigate the cutting fluid terrain, including the different types, critical factors to consider in your choice of a suitable cutting fluid, and other practical tips. So, without wasting any of your . When using a number 10 screw, the recommended drill bit size is usually 3/32 inches or 2.38125 millimeters. This ensures a snug fit and maximum strength. Another factor to consider is the material of the drill bit. Options include high-speed steel (HSS) or carbide. So be sure to choose the right size and type for optimal results!

0 · machining coolant concentration chart

1 · cutting fluid near me

2 · cutting fluid for stainless steel

3 · coolant or cutting fluid

4 · coolant concentration for cnc machines

5 · cnc cutting fluid coolant

6 · best cutting fluid for aluminum

7 · best coolant for cnc machines

Proper installation is important for the safe use of electrical boxes. Make sure the box is securely fastened to the framing or wall structure, and use the appropriate fasteners and methods listed by the manufacturer. Maintain proper box fill calculations to avoid . See more

Cutting fluid, also known as coolant, cutting oil, cutting compound, or lubricant, is a kind of industrial liquid used in process of metal cutting like CNC machining to cool and lubricate . Soluble oils are the least expensive cutting fluids and the most common in machining operations. These so-called emulsions have excellent .

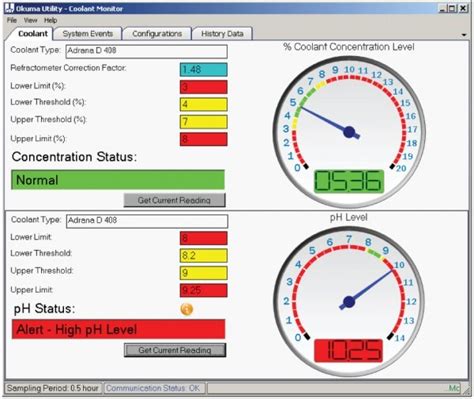

What kills bacteria in CNC coolant? Cutting fluids should have a pH of around 8.6 or higher to inhibit bacterial growth and prevent corrosion of metal surfaces. Monitor pH with a meter or test strips weekly. If pH gets low, use a .Cutting fluids play a crucial role in CNC machining, improving efficiency, precision, and tool life. But how do they work, and why are they so essential? These fluids not only cool and lubricate .We have written this comprehensive guide to help you navigate the cutting fluid terrain, including the different types, critical factors to consider in your choice of a suitable cutting fluid, and other practical tips. So, without wasting any of your .

During CNC machining, the nozzle near the cutting area ejects an oil-like liquid called cutting fluid. This cutting fluid is a lubricant used in CNC machines for lubrication, cooling, and cleaning. As a result, cutting fluid is crucial in CNC .Cutting fluid, also known as coolant, cutting oil, cutting compound, or lubricant, is a kind of industrial liquid used in process of metal cutting like CNC machining to cool and lubricate cutting tools and work pieces. Ever wondered how the right cutting fluid can transform your machining process? This article dives into the essentials of selecting cutting fluids for CNC machining, highlighting their impact on tool life, surface quality, and efficiency. Discover practical tips and insights to enhance your machining operations and achieve superior results.

Soluble oils are the least expensive cutting fluids and the most common in machining operations. These so-called emulsions have excellent cooling and average lubricating properties. Soluble oils are created when mineral oil is added to water in specific percentages. What kills bacteria in CNC coolant? Cutting fluids should have a pH of around 8.6 or higher to inhibit bacterial growth and prevent corrosion of metal surfaces. Monitor pH with a meter or test strips weekly. If pH gets low, use a pH adjuster to raise the pH of the fluid, or replace the cutting fluid. What do you do with old CNC coolant?Cutting fluids play a crucial role in CNC machining, improving efficiency, precision, and tool life. But how do they work, and why are they so essential? These fluids not only cool and lubricate but also help in chip removal and corrosion prevention, ensuring optimal machine performance.

We have written this comprehensive guide to help you navigate the cutting fluid terrain, including the different types, critical factors to consider in your choice of a suitable cutting fluid, and other practical tips. So, without wasting any of your time, let’s dive right in.

machining coolant concentration chart

During CNC machining, the nozzle near the cutting area ejects an oil-like liquid called cutting fluid. This cutting fluid is a lubricant used in CNC machines for lubrication, cooling, and cleaning. As a result, cutting fluid is crucial in CNC machine automatic machining.Cutting fluids, also known as “coolant”, “metalworking fluid”, or “machining fluid”, not only lubricate and cool the cutting area but also help remove chips, preventing overheating and wear of the . A cutting fluid is continuously pumped onto the machining area, creating a flood of fluid that helps to dissipate heat, lubricate the cutting action, and flush away chips. This method ensures consistent cooling and lubrication throughout the milling process, improving tool life . It's no secret that high-quality metal cutting tools and workholding help to increase productivity, but have you stopped for a moment to consider that cutting fluids are the lifeblood of CNC machining operations?

Cutting fluid, also known as coolant, cutting oil, cutting compound, or lubricant, is a kind of industrial liquid used in process of metal cutting like CNC machining to cool and lubricate cutting tools and work pieces. Ever wondered how the right cutting fluid can transform your machining process? This article dives into the essentials of selecting cutting fluids for CNC machining, highlighting their impact on tool life, surface quality, and efficiency. Discover practical tips and insights to enhance your machining operations and achieve superior results.

Soluble oils are the least expensive cutting fluids and the most common in machining operations. These so-called emulsions have excellent cooling and average lubricating properties. Soluble oils are created when mineral oil is added to water in specific percentages.

What kills bacteria in CNC coolant? Cutting fluids should have a pH of around 8.6 or higher to inhibit bacterial growth and prevent corrosion of metal surfaces. Monitor pH with a meter or test strips weekly. If pH gets low, use a pH adjuster to raise the pH of the fluid, or replace the cutting fluid. What do you do with old CNC coolant?Cutting fluids play a crucial role in CNC machining, improving efficiency, precision, and tool life. But how do they work, and why are they so essential? These fluids not only cool and lubricate but also help in chip removal and corrosion prevention, ensuring optimal machine performance.We have written this comprehensive guide to help you navigate the cutting fluid terrain, including the different types, critical factors to consider in your choice of a suitable cutting fluid, and other practical tips. So, without wasting any of your time, let’s dive right in.During CNC machining, the nozzle near the cutting area ejects an oil-like liquid called cutting fluid. This cutting fluid is a lubricant used in CNC machines for lubrication, cooling, and cleaning. As a result, cutting fluid is crucial in CNC machine automatic machining.

Cutting fluids, also known as “coolant”, “metalworking fluid”, or “machining fluid”, not only lubricate and cool the cutting area but also help remove chips, preventing overheating and wear of the . A cutting fluid is continuously pumped onto the machining area, creating a flood of fluid that helps to dissipate heat, lubricate the cutting action, and flush away chips. This method ensures consistent cooling and lubrication throughout the milling process, improving tool life .

cutting fluid near me

Proudly Made in the USA with Global Materials in Sedalia, Missouri. 21-in. Wide 3 Drawer Metal Tool Box is what you need to store your most used hand tools. This durable steel chest can .

cnc machine cutting fluid|cutting fluid for stainless steel