cnc machine controller circuit diagram A CNC machine wiring diagram is a documented blueprint detailing the electrical connections necessary to power a CNC machine. The diagram typically includes a connection point map with detailed diagrams of the . This highly interactive write-in workbook covers all the essential aspects of level 1 and 2 Welding & Fabrication theory including thorough QCF unit coverage of welding processes, metal fabrication & thermal cutting, as well as engineering materials & operations.

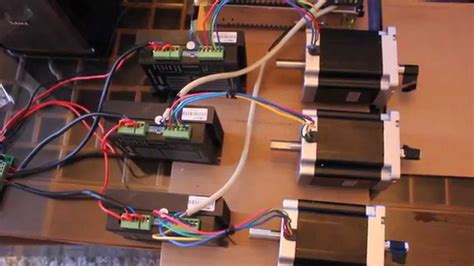

0 · wiring cnc electronics

1 · cnc wiring tutorial

2 · cnc power supply wiring diagram

3 · cnc motor wiring diagram

4 · cnc electronics wiring diagram

5 · cnc controller setup

6 · build cnc controller for router

7 · build a cnc controller

Explore the basics of cutting, bending, and welding all in one condensed interactive format. Using FMA’s textbook "Metal Fabrication: A Practical Guide", the workshop follows the full process of metal fabrication. Training is .

Creating a CNC wiring diagram requires a good understanding of electrical circuits and the specific requirements of your CNC machine. It is recommended to consult the documentation provided with your CNC machine kit or seek . Building instruction for a CNC controller based on the DDCS V3.1 offline controller. Includes wiring diagram and parameter settings.Topic for Mondays, Wednesdays and Fridays: Microcontroller programming and circuit building. This tutorial will make you an expert in wiring CNC electronics using a parallel breakout board and standard stepping motors and stepping .Grbl is an open-source firmware designed specifically for controlling CNC machines. The controller board is responsible for interpreting G-code commands and sending the appropriate signals to the various motors and actuators of the .

A CNC machine wiring diagram is a documented blueprint detailing the electrical connections necessary to power a CNC machine. The diagram typically includes a connection point map with detailed diagrams of the .Educate readers on how to read and interpret a CNC machine electrical wiring diagram. Explain the symbols, notations, and color coding commonly used in wiring diagrams. Break down the .

In this section, we will introduce the key components that make up a CNC machine circuit diagram. These include the power supply, motor drivers, control panel, input/output devices, .In a CNC machine, the circuit diagram includes various components such as power supplies, motors, drivers, sensors, and the controller. The power supply provides the necessary .The wiring diagram and circuit design for CNC machines play a crucial role in ensuring their optimal functioning and precision. This article will provide an overview of the key components and considerations when creating a wiring .Computer Numerical Control (CNC) machines have emerged as a revolution taking the burden of these oppressions and streamlining the manufacturing process. A central part of CNC .

Creating a CNC wiring diagram requires a good understanding of electrical circuits and the specific requirements of your CNC machine. It is recommended to consult the documentation provided with your CNC machine kit or seek professional advice to ensure accurate wiring.

wiring cnc electronics

Building instruction for a CNC controller based on the DDCS V3.1 offline controller. Includes wiring diagram and parameter settings.Topic for Mondays, Wednesdays and Fridays: Microcontroller programming and circuit building. This tutorial will make you an expert in wiring CNC electronics using a parallel breakout board and standard stepping motors and stepping motor drivers.Grbl is an open-source firmware designed specifically for controlling CNC machines. The controller board is responsible for interpreting G-code commands and sending the appropriate signals to the various motors and actuators of the machine. A CNC machine wiring diagram is a documented blueprint detailing the electrical connections necessary to power a CNC machine. The diagram typically includes a connection point map with detailed diagrams of the different cables .

Educate readers on how to read and interpret a CNC machine electrical wiring diagram. Explain the symbols, notations, and color coding commonly used in wiring diagrams. Break down the different sections of the diagram.

In this section, we will introduce the key components that make up a CNC machine circuit diagram. These include the power supply, motor drivers, control panel, input/output devices, and spindle control unit. We will explain the purpose of each component and how they contribute to the overall functionality of the machine. 3.

In a CNC machine, the circuit diagram includes various components such as power supplies, motors, drivers, sensors, and the controller. The power supply provides the necessary electrical energy to run the machine, while the motors convert this energy into mechanical motion.

cnc wiring tutorial

cnc power supply wiring diagram

cnc motor wiring diagram

The wiring diagram and circuit design for CNC machines play a crucial role in ensuring their optimal functioning and precision. This article will provide an overview of the key components and considerations when creating a wiring schematic for CNC machines.Computer Numerical Control (CNC) machines have emerged as a revolution taking the burden of these oppressions and streamlining the manufacturing process. A central part of CNC machines' operation involves understanding as well as working with the CNC machine circuit diagrams.

Creating a CNC wiring diagram requires a good understanding of electrical circuits and the specific requirements of your CNC machine. It is recommended to consult the documentation provided with your CNC machine kit or seek professional advice to ensure accurate wiring.

Building instruction for a CNC controller based on the DDCS V3.1 offline controller. Includes wiring diagram and parameter settings.

Topic for Mondays, Wednesdays and Fridays: Microcontroller programming and circuit building. This tutorial will make you an expert in wiring CNC electronics using a parallel breakout board and standard stepping motors and stepping motor drivers.Grbl is an open-source firmware designed specifically for controlling CNC machines. The controller board is responsible for interpreting G-code commands and sending the appropriate signals to the various motors and actuators of the machine. A CNC machine wiring diagram is a documented blueprint detailing the electrical connections necessary to power a CNC machine. The diagram typically includes a connection point map with detailed diagrams of the different cables .

Educate readers on how to read and interpret a CNC machine electrical wiring diagram. Explain the symbols, notations, and color coding commonly used in wiring diagrams. Break down the different sections of the diagram.In this section, we will introduce the key components that make up a CNC machine circuit diagram. These include the power supply, motor drivers, control panel, input/output devices, and spindle control unit. We will explain the purpose of each component and how they contribute to the overall functionality of the machine. 3.In a CNC machine, the circuit diagram includes various components such as power supplies, motors, drivers, sensors, and the controller. The power supply provides the necessary electrical energy to run the machine, while the motors convert this energy into mechanical motion.

The wiring diagram and circuit design for CNC machines play a crucial role in ensuring their optimal functioning and precision. This article will provide an overview of the key components and considerations when creating a wiring schematic for CNC machines.

alloy wheel cnc machine manufacturer

allied molded electrical box

Preventing burn-through and warping when welding sheet metal is all about controlling the heat. Choose the right welding process and filler metal, and follow these common tips to help ensure success.

cnc machine controller circuit diagram|cnc wiring tutorial