how to cut slots in sheet metal Angle grinder and/or 2~3" air cutoff cool can work to piece sheet metal. Air nibbler does wonders IF you clamp a guide to the metal, 3/16" oversized to what you need. I once . MIG welding is the preferred method for most automotive bodywork, and since sheet metal is the thinnest of metals, a large, expensive MIG unit is usually not required. The majority of sheet metal repair that I've done was with a 90-amp, 110-volt welder.

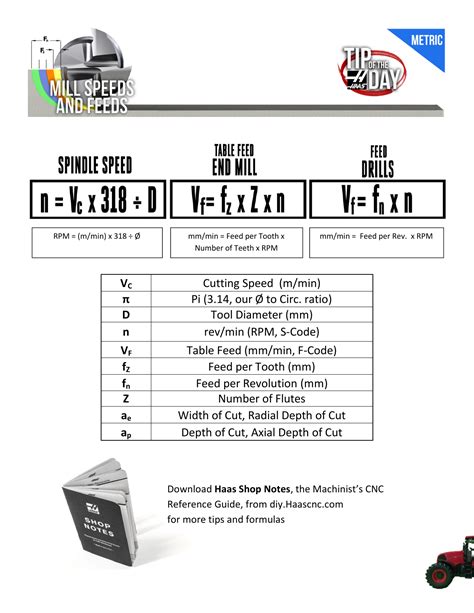

0 · slot milling speeds and feeds

1 · side milling with end mill

2 · milling slots in steel

3 · grooving cutter internal slot

4 · end mill vs slot drill

5 · end mill vs slot

6 · difference between groove and slot

7 · cutting slotted holes in steel

Oxy-Acetylene welding involves joining two metals with the help of a flame produced by the combustion of oxygen and acetylene. The gases are transported from the gas cylinders to the welding or cutting torch through hoses, and the flame is emitted through the nozzle at the end of the torch.

Consider these important design tips when creating holes and slots in sheet metal parts.More information on this Tech Tip available at: https://rapidmanufact. Angle grinder and/or 2~3" air cutoff cool can work to piece sheet metal. Air nibbler does wonders IF you clamp a guide to the metal, 3/16" oversized to what you need. I once . How To Cut Slotted Holes in Steel with a Drill Press. This isn't the safest way to cut slotted holes in steel, but it worked surprisingly well. All you need is a drill press, a HSS. All you need is a drill and a counter so follow this video and you can cut a slot, a circle or any shape in metal.

slot milling speeds and feeds

side milling with end mill

Your best bet for making these slots would probably be a Dremel (or similar) with a cutoff wheel. Another option would be to simply punch the slots with a sheet .Sheet metal is easy to work with and is popularly used in metal fabrication. The most complicated part in the sheet metal fabrication process is opening up a slot in the sheet metal. There are many options for doing this but most will require .

Slot milling can cut deeper slots, reduce the difficulty of processing, and increase the efficiency and accuracy in processing. It is particularly suited for precision machining of detailed workpieces but may .

This post is about a hole cutting method that can be done by hand with rudimentary and cheap equipment. Simple hole cutting tools. A simple craft knife can be used to effectively on sheet metal for hole cutting without .

One workaround here is to cut the slot through the bend, eliminating the need to leave material to come around. In the example in the related image, the top slot will deform badly, the bottom slot will not. Narrow . However I have done well on drilling overlapping holes. You can divide the drill diameter into approximately thirds, you will be adjusting the drill diameter towards the .The other thing I had to tackle is that even though I was using rectangles the same size or smaller than my programmed kerf width (.05"), sheetcam, which I use for post processing, was trying to cut a full rectangle out, instead of just a .

Dear Viewers, In this video you will learn that how to make a Cut Across Bend for creating the slot in Sheet Metal with help of Fold, Unfold and Extruded-Cu.

Use the dremel with the fibre cut off wheel to cut your slot. You will need to cut the ends to both sides of your piece since the tool and shaft get in the way of going all the way down. drill two holes, one for each end of your slot to finish the cut cleanly. Use layout dye and an awl to make sure your cuts are true. You are sometimes faced with creating a cutout in sheet metal through multiple thicknesses and bends. Normally you would Unfold the sheet metal body, sketch. In this video I show how a nibbler works and how to use one. (02:18 Listen to my reaction! 🤣) I had never used a sheet metal nibbler before this! It's an e. 7 Best Ways to Cut Metal with Power Tools. Next up, let’s take a look at the best ways to cut metal if you have power tools at your disposal. Using a Nibbler. If there were any one power tool that acted as a simple upgrade for a familiar metal-cutting hand .

Choose from our selection of metal slotting cutters, including over 5,300 products in a wide range of styles and sizes. . Use these end mills for general purpose keyseat cutting in a wide range of material, including aluminum, iron, and steel. They mill precise notches in rotary shafts to fit machine keys and can also be used for slot milling. The slot dimensions are 0.5" wide x 8" long and its a thru slot and it has 2 holes on either side thus making it oblong in shape. I'm looking to speed-en up the process, and was looking at the following options by getting a custom machine made for the process: 1. Use an abrasive wheel. 2. Use a Metal slitting wheel? 3. Use a band-saw? A demonstration of how feature templates can be used to build tabs and slots in sheet metal in a single feature.

milling slots in steel

I'd like to create intersecting keyed slots in sheet metal parts. I tried using the "intersect" tool, but it wouldn't allow me to use that tool with sheet metal. So I tried with extruded non-sheet-metal bodies, and the intersect tool "worked", but I couldn't make it do "half height slots" like I'm looking to do. Here's an example model I'm .

The first way is very simple, I am just going to create a slot on a plane and cut through the part. I just created a regular through all cut and it creates the slot on the curved surface with a normal to cut. So when you flatten the part, you can see the cut is straight through the part as you would expect it to be in a flat pattern. How to cut a slot in mild steel using only home workshop tools, ie. without the need for more industrial machinery such as a milling or shaping machine.

Solidworks sheet metal tab and slotSolidworks Sheet Metal TutorialTab and Slot SolidworksTab and Slots Sheet metal Solidworks Tab and Slot Design Tab and Slo.

Notches, tabs, and slots are three common sheet metal design elements that can help you in more ways than you might initially think. Designing them properly is key. . we tend to run into cut quality issues. The slot in the example here is 1/2 material thickness and could be blown out by the laser-cutter making it impossible to hold tolerances . In Sheet Metal I would do as follows, *Mark slots with scribe by using the original plate. *Pree-drill as much material as possible leaving about 1/8 material inside scribe line. *Clamp the original Plate with a 1/2" spacer onto . Quick video showing how to program relief cuts or straight line cuts in fusion 360 for plasma CNC table users. I use this in order to add relief cuts to my p. The cut is difficult because of the heavier gauge, and cutting through the up-across-down-across pattern. I tried a tin snip, no good. My next move was going to be an angle grinder with a thin metal blade or a diamond .

Like most metalworking tools, press brakes, pan brakes and sheet metal brakes can be expensive, and unless you have one in your garage, you’ll need to pay a metal fabricator to bend your parts. Here at SendCutSend, CNC bending is a pretty simple process, especially when we’re already cutting your parts for you. But sometimes, a design can . Incorporating slot and tab features into your sheet metal parts increases flexibility, decreases cost during fabrication, and allows for a more streamlined design process. Please note that the numbers in this article lean on the conservative end and that for large-scale production runs, we recommend testing the sizes first. In this video, I am going to explain about how to create "Finger Joints With Tab & Slot Feature" in SolidWorks - Sheet Metal Module. Here, I am going to expl. All you need is a drill and a counter so follow this video and you can cut a slot, a circle or any shape in metal.

We had to make our own special tooling to cut some internal key ways that a standard broach would not work. It could be done in a standard bridgeport style . This video is about Slot Cutting TipCheck out my Amazon store for some of my favorite products. Purchases will support content I make: https://www.amazon.c.If I were forced to make a slot in a cube using only a lathe I think I'd set the cube on the cross slide and elevate it using gage blocks and clamp it down, spin the end mill in the lathe jaws, and cut the slot using the cross slide. Holes and slots are critical features in sheet metal fabrication, they are created with punching, laser cutting, drilling, and other appropriate technologies. . Custom cut sheet metal shapes flat metal sheets into customized products. read more. A Complete Guide To Aluminum Stamping Process. Oct 12, 2024.

New in SOLIDWORKS 2012 is the ability to have an extruded cut across a sheet metal bend that doesn't go through the entire thickness and is still able to be .Cutting a thin slot in sheet aluminium . If you can get the work holding down and make up a good tool to check the width of the slot (could just be a strip of metal) then you shouldn't find any problem working aluminium by hand. 5mm sounds thick for a control panel face, you might have some more options in a thinner material and it'll still .

The most important rules while welding thin stainless steel is to use the right welding techniques- that is using the right filler diameter, tungsten electrode, welding parameters along with shielding gas flow rate.For thin sheet metal welding it can be 30 ampere while for thicker (e.g. 1/8” square groove weld)- it can go up to 220 ampere for example. GMAW-S gives low heat and makes it easy to use in all positions on sheet metal, low .

how to cut slots in sheet metal|milling slots in steel