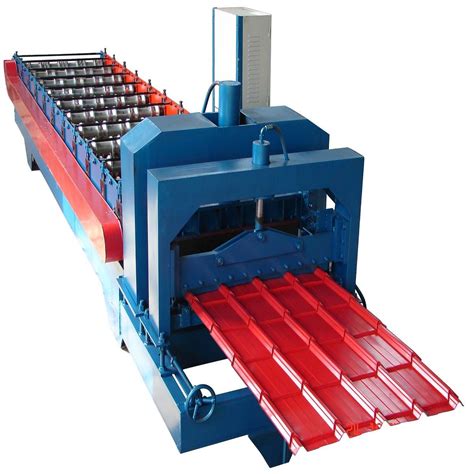

metal sheet roller: efficient and precise metal forming Discover the exceptional features and benefits of our Metal Sheet Roller, the ultimate tool for precision metal forming. With adjustable settings, durable construction, and versatile . Get information, directions, products, services, phone numbers, and reviews on Yellow Jacket Welding & Metal Works in Mineola, undefined Discover more Welding Repair companies in .

0 · sheet roll forming tools

1 · sheet roll forming equipment

2 · sheet metal forming machine

3 · metal sheet roll forming machine

Made of heavy-duty polyethylene, the Tractor Supply 44 in. x 19 in. Heavy-Duty Poly Utility Storage Box is durable, rustproof, and lightweight. It also includes 2 lockable heavy hasps and a continuous recessed hinge.

sheet roll forming tools

Discover the exceptional features and benefits of our Metal Sheet Roller, the ultimate tool for precision metal forming. With adjustable settings, durable construction, and versatile . Sheet metal roll forming is a highly efficient and cost-effective manufacturing process used to shape flat sheets of metal into complex, customized profiles. This technique involves passing the metal through a . Sheet metal working is a critical aspect of various industries, including automotive, aerospace, construction, and electronics. To achieve precision and efficiency in this process, modern sheet metal working machines leverage advanced technologies and innovative designs. Here are the top 10 sheet metal working machines that revolutionize precision and efficiency: . In the realm of metal fabrication, sheet metal forming machines are the linchpins of precision and efficiency. Unleashing their transformative power requires meticulously designed workflows that orchestrate every stage, from raw material to finished product. By embracing the following principles, manufacturers can forge streamlined processes that unlock unparalleled .

Bending Brakes: Used for making precise bends in sheet metal. They can be manual or powered and are essential for creating consistent joggles. . The primary components of edge rolling tools are rollers and forming dies. The rollers apply pressure to the edges of the sheet metal, gradually bending them to the desired angle while the dies .In the realm of metalworking, shear metal cutting machines stand out as indispensable tools, renowned for their precision and efficiency. These machines employ a scientific approach to deliver clean and accurate cuts with minimal distortion, making them essential for a wide range of industrial applications. Precision Cutting: A Geometric Endeavor

cnc turning parts suppliers in india

Advanced sheet metal forming machines employ precision control algorithms that minimize waste by optimizing material utilization. This reduces the need for raw material extraction and processing, conserving precious natural resources and lowering carbon emissions. . The adoption of energy-efficient sheet metal forming machines is a strategic .In the realm of metalworking, where intricate designs and precise dimensions reign supreme, sheet roll forming machines stand out as technological marvels. These machines employ a captivating dance between metal and machinery, transforming flat sheets into a symphony of shapes with precision and efficiency. Unveiling the Magic: Roll Forming in . Roll forming machines revolutionize metal processing, unlocking the potential for complex and precise metal shapes. Their applications span numerous industries, catering to the diverse needs of modern manufacturers. Through their efficiency, precision, and versatility, roll forming machines continue to shape our world, one intricate design at a .Sheet metal stamping is a cold-forming process using presses and dies to shape materials. It works with various metals, including stainless steel, carbon steel, aluminum, brass, and copper. . Our advanced equipment ensures precision and efficiency in cutting, forming, and assembly. Whether you need custom prototypes or high-volume production .

This precision is essential for creating parts that meet strict dimensional tolerances and functional requirements. Increased Efficiency. Sheet bending machines significantly increase the efficiency of metal forming processes. They offer high bending speeds, automated operations, and the ability to handle multiple sheets simultaneously. In the world of metal fabrication, the sheet metal roller stands tall as a versatile and indispensable tool. Designed to shape and bend metal sheets with precision, a sheet metal roller is commonly used in industries such as automotive, aerospace, construction, and manufacturing. This article delves into the functionality, types, and applications of sheet metal rollers, .

The precision of sheet metal rolling machines serves as a catalyst for innovation. Designers can now explore intricate geometries and complex shapes, pushing the boundaries of metal fabrication. . The Advantages of Using a Sheet Roll Forming Machine in Manufacturing . Maximizing Efficiency- How a Sheet Metal Folding Machine Transforms Your . Servo-electric press brakes employ servo motors to achieve high precision and energy efficiency. Roll Forming. Roll forming is a continuous sheet metal forming process that gradually shapes the material using a series of rollers. It is commonly used to produce components with consistent cross-sections, such as rails, tubes, and profiles. Whether you're new to the concept or looking to deepen your understanding, this guide will take you through the basics and explore the vast potential that metal roll forming holds. The Basics of Metal Roll Forming. Metal roll forming is a manufacturing process that transforms metal coils or sheets into various complex shapes and profiles. This .【DURABLE & HIGH CAPACITY】- Rollers constructed of precision ground steel Slip Roll provids strength and stability while forming your sheet metal. For metal forming on metal plate up to 320mm in wide x 1.0mm thick(st37).

Bump-forming is the best solution for rapid sheet metal fabrication when working with prototypes or low-volume orders, aiming for precision, and looking to minimize costs. It's a cost-effective and efficient way to produce .

Cold roll forming machines are a vital part of many manufacturing processes, and they offer a number of advantages over other forming methods. These advantages include improved efficiency, precision, and versatility. As the name suggests, cold roll forming involves passing metal through a series of rollers to shape it into the desired profile.

A roll forming machine and die can make metal fabrication look like magic—but diving into roll forming sheet metal shows the process behind your product. . This process is efficient and incredibly precise due to the seamless . Material Efficiency: Metal forming processes typically do not remove material but instead deform it into the desired shape, which minimizes waste. This efficiency is crucial for cost control and environmental sustainability. . frames, and engine parts. Advanced techniques like stamping, hydroforming, and roll forming are employed to meet high . Reshaping the Industry: Embracing the Next Frontier of Metal Sheet Forming. The realm of metal sheet forming is undergoing a profound transformation, propelled by technological advancements that are revolutionizing the way sheet metal is shaped and manipulated. This article delves into the captivating trends and innovations that are redefining .

sheet roll forming equipment

Designed with precision and efficiency. From bending to cutting our machines ensure ease in shaping metal. . Sheet Metal Roller, Slip Rolling Bending Machine with Two Removable Rollers (23) 227.99 236.99 Deal after registering Member discounted price. 227.99 . High Precision . VEVOR metal forming machines provide high precision and accuracy . The Advantages of Using a Sheet Roll Forming Machine in Manufacturing 2024/09/14. How to Optimize Your Laser Sheet Cutting Machine for Maximum Performance 2024/09/12. How to Maximize Efficiency with Modern Sheet Metal Working Machines . Innovative Techniques in Sheet Metal Folding- Enhancing Precision and Quality

The intricate world of metalworking demands precision and efficiency, where every bend, fold, and cut must align with exacting specifications. Enter the realm of metal sheet forming machines, where cutting-edge technology empowers manufacturers to achieve unparalleled accuracy and productivity. Unwavering Precision Unlike manual forming techniques, which rely . Efficient Sheet Roller, Precise Former, 3 Station Roller for Bending Metal Roofing Materials - Amazon.com. Skip to main content.us. Delivering to Lebanon 66952 Update location Tools & Home Improvement. Select the department you want to search in . Plate rolling machines are powerful tools that offer precision and efficiency in shaping metal plates. Their ability to handle diverse materials, achieve precise geometries, and automate processes makes them valuable assets in various metal fabrication industries. . The Advantages of Using a Sheet Roll Forming Machine in Manufacturing 2024/09 .The components of machines used in metal forming processes such as metal spinning, flow forming, shear forming, and wheel forming are designed to deliver precise control and high-quality production. Each machine type is equipped with specialized parts that cater to the unique demands of the specific forming process.

Types of Sheet Metal Bending Machines. Three-Roll Benders: These machines utilize three rollers to perform continuous bending, offering high precision and productivity. Ideal for cylindrical and conical shapes. Press Brakes: Equipped with a punch and die, press brakes apply pressure to bend the metal sheet. In the realm of automotive engineering, the precision and efficiency of metal sheet forming machines have revolutionized the production process. These machines, the unsung heroes of the assembly line, play a pivotal role in shaping the very essence of every vehicle we drive. Metal sheet forming machines are the masters of malleability.

sheet metal forming machine

metal sheet roll forming machine

“Very good- condition for its age minor scratches, dents and paint loss for 1968 unrestored all ”. Read more. US $19.78USPS Priority Mail®. Includes 4 business days handling time after receipt of cleared payment. Seller does not accept returns. *No Interest if paid in full in 6 months on $99+. See terms and apply now.Stopping in a yellow box junction could cost you up to £130. We explain the rules, so you can stay safe and avoid a fine. A study by the RAC .

metal sheet roller: efficient and precise metal forming|sheet roll forming tools