parts of a cnc milling machine Parts of a CNC milling machine include a column, base, knee, power feed mechanism, a work table, ram, spindle, milling tool, milling chuck, CNC controller, and an overhanging arm along with arbor support in case of . The process usually requires heating the two pieces of sheet metal up to the melting point, then using a torch to weld them together. The Welding sheet metal process is commonly found on aircraft, cars, trucks, appliances, boats, ships, and other industrial equipment.

0 · schematic diagram of cnc machine

1 · milling machine parts list

2 · cnc milling machine diagram

3 · cnc machine parts list pdf

4 · cnc machine parts diagram

5 · cnc lathe parts diagram

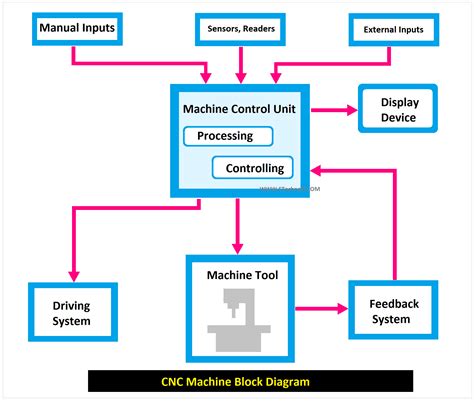

6 · block diagram of nc machine

7 · block diagram of cnc machine

The E6013 welding rod is the best to stick weld thin mild steel and is known as a sheet metal rod. An E6013 has a flux covering with high amounts of rutile. Rutile creates the smoothest arc with light penetration that won’t burn through the joint as easily as other rods.

round electric box cover

Although the milling operations on the two styles of milling machines might vary, the milling machine parts that make them up have much in common. We’ve created a list of the essential parts of a CNC milling machine . Parts of a CNC milling machine include a column, base, knee, power feed mechanism, a work table, ram, spindle, milling tool, milling chuck, CNC controller, and an overhanging arm along with arbor support in case of .

CNC milling is a subtractive manufacturing process where material is removed from a solid block to create parts. That being said, there are basic components in every CNC mill that allow it to function as intended. I’ve . Spindles in milling machines may have different types of tool holders, such as collets, end mill holders, or drill chucks. These tool holders securely grip the cutting tools, ensuring stability and precision during . Milling machines with CNC are an integral part of the manufacturing industry with a unique design that sets them apart from their vertical counterparts mill machine without CNC. These CNC machines feature .A CNC milling machine is a computer-controlled automation device that shapes materials into precise parts using cutting tools and controlled movements. What propels these machines into action? How do these devices meet project .

round electrical box plug

What are the Parts of a CNC Machine? Bed: Typically constructed from cast iron for enhanced durability and strength, the bed is the machine’s foundation, supporting all components.. Spindle: Inside the machining area, the electrically driven spindle rotates tools that cut and shape the parts. The inside of the spindle is tapered to match the tapered angle of the tool holder to .Common types of CNC machines include: CNC lathes, CNC milling machines, CNC routers, 3D printers, and laser and plasma cutters. In this article, I will focus on the basics of CNC milling machines. Read on to learn everything you need to know, from CNC milling machine parts to how CNC milling works and everything in between.CNC milling machines are among the most versatile and widely used in the industry. Call (407) 298-9171; AS 9100 D / ISO 9001:2015 Certified; Connect with us: . CNC lathes are specifically designed for producing cylindrical parts. By rotating the workpiece against a fixed cutting tool, these machines can create smooth, round objects like .CNC Milling Machines: First, CNC milling machines use rotary cutting tools to remove material from a workpiece and make it into a shape or form that the user wants. These CNC machines help cut, shape, and drill different kinds of materials. They are often used to make precise and complicated parts. Key Components:

Machine Tool. The machine tool is the part of the CNC machine that actually performs the cutting, drilling, or milling operations. It can be a spindle holding various types of cutting tools or other attachments depending on the machine's purpose. The tool's movement is precisely controlled to shape or cut the material. 5. Feedback System 3. Introduction to CNC 3 Numerical control (NC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium, as opposed to controlled manually. Most NC today is computer numerical control (CNC), in which computers play an integral part of the control. In modern CNC systems, end-to-end component .

CNC Milling Machines. Milling machines are the most common CNC equipment. They use a multi-point rotating cutting tool attached to a CNC-controlled spindle. Consequently, the spindle can move across multiple axes (3, 5, or more) to remove the material. . If your parts require accurate and precise parts, check the capabilities of CNC machines . Unlock the potential of your milling machine with our comprehensive guide to the essential parts of milling machines. Explore now! Parts Of Milling Machine. . CNC milling machines are computer-controlled milling machines. They offer precise control and automation, allowing complex shapes and designs to be easily machined. The most common . 1.3 Theory of CNC Milling Machine 1.3.1 Characteristics of CNC Milling Machine Tools Work part machining on CNC machine tools requires controllable and adjustable infeed axes which are run by the servo motors independent of each other. CNC- milling machines (Figure 1.7) on the other hand have at least 3 controllable or adjustable feed axes . CNC mills are often classified by the number of axes on which they can operate or spindle directions. 1. Vertical Mill. A vertical mill or milling machine’s spindle axis is vertically oriented, which means the cutting tools on the spindle will shape the materials vertically, and the cutters move while the workpiece remains stationary, the machines can cut into the part easily.

CNC 101 Milling Machine Parts - this is the second video in my updated CNC 101 series where I walk through the parts of a CNC machine, explain what each part. Choosing the right material is crucial for the functionality and durability of your CNC milling parts. Advantages of CNC Milling Parts. Precision: CNC machines offer high accuracy, ensuring parts meet exact specifications. Repeatability: Ideal for producing multiple identical parts. Versatility: Capable of creating complex shapes and intricate .

Milling is suitable for many different features, including threading, chamfering, slotting, etc. This makes it possible to produce complex designs using a variety of different milling operations: Surface milling, face milling, angular milling, form .

A CNC milling machine parts Bed. The hardened part of the machine that carries all the load. All the other components are mounted over the bed. It is made of hard metal, and as the tool turret travels over this part. .The main components of a CNC milling machine include the spindle, which holds and rotates the cutting tool; the worktable, where the workpiece is secured; and the axes that control the motion of the spindle and table. . By optimizing the design for CNC milling, parts can be produced more efficiently and accurately, ultimately leading to .Traditional machine operations like lathes, milling, and drilling have historically relied heavily on manual control, leading to reduced accuracy and precision and requiring significant human effort and time. . Parts of a CNC Machine. This section aims to provide an overview of the various components found in CNC machines. While certain parts . CNC machines also offer a high degree of repeatability, which means that the same part can be produced consistently and accurately over time. 15 Parts of CNC Machine. A CNC machine consists of several main parts that work together to produce precision parts and components. Here are the 15 main parts of a CNC machine and their functions:

This model supports complex part manufacturing, leading to improved workflow and resource management. The machine's user-friendly design integrates well into different production environments, serving specialized or general manufacturing tasks. What is Acer 1440G? The Acer 1440G is a type of CNC milling machine optimized for a range of delicate . Their CNC Swiss and CNC turning machines can handle parts ranging from 0.145″ to 3.25″ in diameter, and they also have the ability to mill features onto turned parts. Whether it’s for large, square, or flat parts, or cylindrical parts with features, the choice between turning and milling ultimately depends on factors such as size . A 3-axis CNC milling machine operation is a computer controlled milling tool that uses a wide variety of cutters on a machined work-piece, to extract the finished shape of a required component in metals like Aluminum, stainless steel etc. and even glass, copper and wood with great surface finish.3 axis CNC mills are essentially no different .

The table is an essential component of a CNC machine as it holds the workpiece securely during machining operations. It provides a stable platform for accurately positioning the material being worked on, ensuring precise cuts or milling actions according to programmed instructions. The table may feature T-slots or clamping mechanisms to secure various types of workpieces in . The CNC machine precisely cuts, shapes, and drills materials according to the design, creating a finished product that matches the original digital blueprint with high accuracy. CNC milling machines can work with a variety of materials, including metal, wood, and plastic. At Worthy Hardware, we use CNC milling to create parts of different sizes .

2. COMPUTER NUMERICAL CONTROL(CNC) INTRODUCTION Computer numerical control CNC) is one in which the functions and motions of a machine tool are controlled by means of a prepared program containing coded alphanumeric data. CNC can control the motion of the work piece or tool, the input parameters such as feed, depth of cut, speed, and . CNC Milling Machines. CNC milling machines are designed to perform tasks such as drilling, cutting, and shaping materials. They have several essential parts that enable them to execute these functions with precision: Spindle Motor: The spindle motor powers the cutting tool, providing the necessary torque and speed for milling operations. It is .

schematic diagram of cnc machine

milling machine parts list

cnc milling machine diagram

Understanding the costs of a sheet metal part will help you evaluate the choices each supplier is making to provide their price. First, let’s take a look at some of the key components of a sheet metal fabrication quote. Typically they include four important areas: materials, labor, services and overhead. You will see in this eBook that costs .

parts of a cnc milling machine|cnc milling machine diagram