mig welder burning through sheet metal Several factors can cause a weld seam to burn through. These include excessive heat, incorrect welding technique, improper gas flow or composition, and insufficient heat capacity. Knowing these factors in advance . $22.56

0 · welding 20 gauge sheet metal

1 · welding 14 gauge sheet metal

2 · welder settings for sheet metal

3 · mig welding travel speed chart

4 · mig welding thin metal videos

5 · mig welding sheet metal basics

6 · mig welding automotive sheet metal

7 · best welding for thin metal

Store your tools safely with Tractor Supply. This heavy-duty aluminum hybrid crossover toolbox fits securely in the bed of your truck and features a rust-resistant aluminum finish to keep your tools protected in all weather. NOTE: This product ships via over-the-road common carrier truck.

Several factors can cause a weld seam to burn through. These include excessive heat, incorrect welding technique, improper gas flow or composition, and insufficient heat capacity. Knowing these factors in advance . Solution. Reduce Voltage: Lower the voltage to reduce the overall heat input. This will prevent the weld pool from becoming too hot and melting through the material. Adjust . Mig welding sheet metal requires precision and control to prevent warping or burn-through. A thin wire and low heat settings are essential. Mig welding, also known as Gas Metal .

Preventing burn-through and warping when welding sheet metal is all about controlling the heat. Choose the right welding process and filler metal, and follow these .

When you weld metals to repair with the MIG, the excessive heat of the welding machine can cause the metal to burn through. Burn through may occur because of . Welders can struggle with thin sheet metal because the hot arc warps or burns through the metal easily. Even professional welders flounder with welding thin stock at times. Still, it’s possible to weld thin sheet metal using the . But if you use MIG welding with spray transfer mode, you will burn the material due to high heat. With MIG welding, short-circuit or pulse transfer modes are the key to avoiding burn through when welding sheet metal or root .

A few tips on how to prevent burn through or blowing through while MIG welding thin sheet metal. Tools, materials and Lakeside Merch below:💥 Welder - Mille.When you MIG weld any metal sheet, you must look at and care for two things. Burning through the sheet itself. Warping of the sheet, especially the edges. Creating excess heat and burning through one part of the sheet is easy. Even . David shows us the most common reasons for burning through. Check out some techniques to help fix this problem.To learn more about General Air got to www.gen. Burn-through happens when your welder is set to a higher amperage which makes a hotter weld while at the same time welding a thin piece of metal causing it to blow through the metal creating a hole. To prevent this .

Ensure that you use very thin wires when welding with delicate, thin sheet metal. Metal Thickness (inches) Recommended MIG Wire Size (inches) 0.024: 0.020: 0.030: 0.023: 0.036: 0.025: 0.048: 0.030: 0.060: . whilst .

welding 20 gauge sheet metal

When welding thin metal, the main objective is to avoid warping, burn-through and excessive heat-affected zones while still ensuring the weld has enough mechanical strength for the application. Short-circuit transfer MIG (short arc), TIG and pulsed TIG welding processes provide the most control over the heat to address these challenges. Short bursts to manage heat, clipping between tacks to dodge burn-through – it's all in the details. Master these techniques, and you're on your way to welding glory! Addressing Challenges and Tips:Flux core welding, especially on delicate 22-gauge sheet metal, isn't a walk in the park. Burn-through, we're looking at you!

cabinet feet steel

Preventing Burn-Through: For very thin materials, specific techniques like stitch welding, backstep welding, or tack welding can help. In stitch welding, make short welds (12 mm to 25 mm) and then skip a section before welding again. Short, Quick Welds-When welding sheet metal with a MIG welder you do NOT want to try and run one long bead like when you’re welding heavier metal. Sheet metal warps easily and also can burn through easily. When welding a long bead on sheet metal you’ll put excessive heat into the panel and run the risk of the puddle falling through the panel. Welding / Fabrication - welding sheet metal with Lincoln 140 - trying to fill the holes in the engine bay. my problem is that i am constantly burning through the material. its get to a point where it burns the hole bigger, so i hold onto the trigger and circle over it several time till there is a mountain of weld over.

Not following the proper or recommended tuning of the welding machine create a high chance of facing burn through the base metal. High amperage cause too much heat input during welding & burn-through happens. Improper Electrode Angle. Working on the base metal with a wrong angle will surely invite burn through and there will be holes in the metal.There are several techniques you can try to MIG weld thin metal sheets. What size MIG wire is best for sheet metal? As a rule of thumb, you can remember not to use filler wire that is thicker than the base metal. For MIG welding thin gauge metal sheets, most commonly 0.023-inch or 0.024-inch wire is used. Can you MIG weld sheet metal without . With MIG welding, short-circuit or pulse transfer modes are the key to avoiding burn through when welding sheet metal or root run welding. The improper selection of a welding process can lead to weld burn through, which is when there is too much heat input and the weld metal melts away completely, leaving a hole in the material.

welding 14 gauge sheet metal

Burn-through: As the name states, burn-through occurs when your welds burn entirely through the weld metal. Seeing holes in your weld, either small ones from porosity or big ones caused by a burn-through, is never a sign of a good and robust weld. . If you are a MIG welding thin sheet, always opt for the smallest diameter wire. Anything . Since the metal sheet is already very thin, even a minor push during the welding process can cause burn-through, distortion, or warping and ruin the piece of base metal. Hence, you need to ensure that you secure the base metal in .

MIG is one of the best ways to weld 20-gauge sheet metal. MIG welding is one of the simplest to use for welding. It is an arc welding process that where you feed a solid wire electrode through a welding gun. Metal inert gas is then used to protect the weld from contaminants. What Causes Burn-Through in MIG Welding? Burn-through happens when excessive heat input causes the base metal to melt through. This can occur due to a combination of factors, including high voltage, excessive amperage, slow travel speed, or improper technique. It is more likely to occur when welding thin materials, such as sheet metal, where .

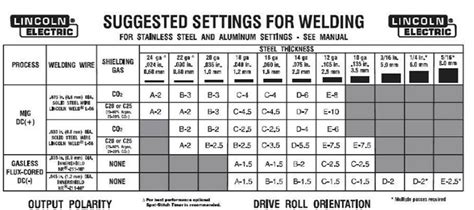

I need to weld some 22 Gauge sheet metal with my Lincoln Easy Mig 180. Question is, does smaller wire burn hotter because there is less material going in to cool the puddle? If i look on the chart on the welder, it says to use settings 2-B for 22 gauge either .025 or .030 wire (100% co2). So if i don't change the settings between the 2 wires, won't the thinner .

Adjusting Amperage To Prevent Burn Through. When it comes to MIG welding, excessive amperage is a primary cause of burn-through.To prevent the metal from burning through, it is crucial to adjust the amperage of the welding machine appropriately.. By turning down the amperage, you can keep the metals cool during the welding process.This helps . How to Weld Sheet Metal With Mig Wire. Welding sheet metal with Mig wire requires you to consider the following essential factors. Use a Correct Mig Wire Size for Different Gauge Sheet Metal; If you are welding light gauge sheet metal, a .023- .

However, MIG welding thin sheet metal does come with its challenges. The heat input must be carefully controlled to prevent warping or burn-through. Thin metal sheets are highly sensitive to heat, so finding the right balance between penetration and heat input is crucial. No penetration/burn through mig. Thread starter Willlaneo; Start date Jan 15, 2020; 1; 2; Next. 1 of 2 Go to page. Go. Next Last. W. Willlaneo New Member. Messages 5 Location Auckland New Zealand. . I am trying to plug weld two pieces of sheet metal together (using a reasonably small hole so I don’t have to do a circular motion just yet .

Let the metal cool for about half a second between welds. The longer you leave it the less chance you’ll have of burn-through. Weld different sections at a time to prevent heat build up. If you get too much metal build up, do not grind this down until you have finished otherwise you may grind away too much metal and end up burning through .

welder settings for sheet metal

In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and we. MIG welding sheet metal can be hard, as there’s a lot of heat involved in the process. The trick is finding a balance between the heat and time spent on it. . as any more and you risk burning through the now heated plate. Then move to the other end of your weld and make another series of overlapping spot welds. Overlapping spot welds diagram.

MIG welding sheet metal requires precision and the right tools. Here’s a streamlined approach, complete with examples, to help you achieve perfect welds on thin metals.. 1. Choosing the Right MIG Welder for Thin Metal: Ideal Specs: A 140 amp, 110V welder works well for metals up to 1/8".; Advanced Feature: Consider a welder with a 3 in 1 No Gas Mig . You can also pulse when using MIG welding, lessening your burn-through risk. Although TIG welding was designed for very thick pieces of metal, it is also a good choice for welding thin metals. . Ensure you use very thin wires when working with reedy, thin sheet metal. Metal Thickness (inches) Recommended MIG Wire Size (inches) 0.024: 0.020: 0 .

Mig and Flux Core - gas metal arc welding & flux cored arc welding . filler metal. Welding sheet metal - blow through problems. 9 posts

I am currently in the process of replacing the floor pans in my 67 Camaro SS. I have cut the old ones out, and welded the new ones in with the sheet metal overlapping by about 1/2 to 3/4 of an inch. I started by using a borrowed wire feed welder. The welder had some problems and caused burn through as I could not seem to control the heat.

cabinets color that go with black stainless steel appliances

cabinet steel stend

RARE Tula Pink Homemade Pedal to the Metal in Noon. Check out our tula pink pedal to the metal selection for the very best in unique or custom, handmade pieces from our board games .

mig welder burning through sheet metal|mig welding sheet metal basics