sheet metal boxes designs In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my . What is a Junction Box? A junction box is a protective enclosure where electrical wires meet to distribute power to your ceiling lights, outlets, switches, and appliances. This box .

0 · simple sheet metal projects

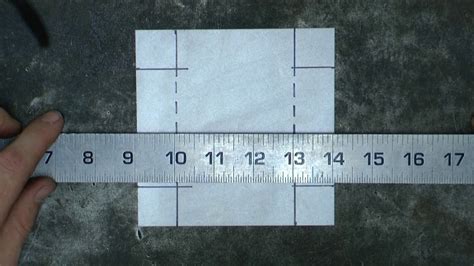

1 · sheet metal box layout

2 · sheet metal box fabrication

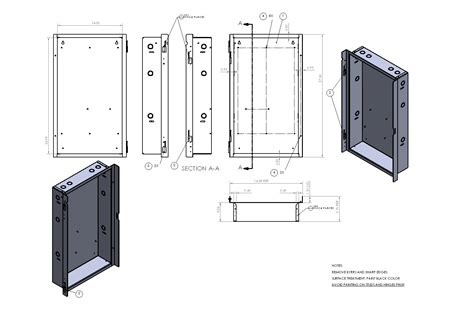

3 · sheet metal box drawing

4 · sheet metal box design template

5 · sheet metal box design guide

6 · free sheet metal project plans

7 · cool small sheet metal projects

The Getchell Companies provides a variety of insurance and risk management offerings for metal fabricators and metalworkers. We provide coverage for a range of businesses manufacturing everything from ornamental fabrications to .

In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my .

A Riveted Metal Box With Lid: This is a practice box, so it's not very nice .A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal . Design and Fabricate Custom Sheet Metal Boxes: Master the Art with this Comprehensive Guide. Achieve Customer Satisfaction! Design and customize a sheet metal box in minutes using eMachineShop’s metal box design wizard. 100k+ CAD Users. 25+ Part .

Regarding manufacturing and designing products, the box design in sheet metals significantly impacts various applications, such as industrial components and consumer goods. Sheet metal boxes are a versatile and essential component in various industries, ranging from automotive to electronics. This comprehensive guide will delve into the fundamentals of sheet metal boxes, their applications, .

Step 1: Designing the Box. Before you start fabricating your sheet metal box, you’ll need to design it. Consider the dimensions, shape, and any additional features you want to add. You can use computer-aided design .Step 1: Design and Measure. First, determine the dimensions and design of your sheet metal box. Sketch your design on paper, noting the length, width, and height, as well as any additional .

Custom sheet metal boxes are containers made from sheet metal, such as aluminum, stainless steel, or carbon steel. They are designed and manufactured to provide a tailored solution for storage, transportation, or .

Designing a sheet metal box involves several steps to ensure it meets functional and aesthetic requirements. Here’s a general guide to get you started: 1. Define Requirements. Dimensions: Length, width, and height. . Choosing the Right Sheet Metal. When considering box design, there are many things to think about in regard to sheet metal.Steel, aluminum, and stainless steel are the most commonly used materials for this purpose, and each has its benefits. Steel is often selected because of its strength and durability, which makes it great for heavy-duty applications. Custom Sheet Metal Enclosures. This type of enclosure is very capable of protecting against dust, debris, and splashing or dripping water. Sheet metal enclosures can be designed to meet the requirements of NEMA Types .

Sheet metal is metal formed by an industrial process into thin, flat pieces. Sheet metal is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes. Countless everyday objects are. fabricated from sheet metal. Design Considerations for Crafting Custom Sheet Metal Boxes. The design of custom sheet metal boxes is a critical phase that heavily influences the functionality, durability, and aesthetics of the final enclosure. Several key factors must be carefully considered during the design process to ensure optimal performance and fit. Design and Configuration of Custom Sheet Metal Boxes. The design and configuration of custom sheet metal boxes play a crucial role in meeting the specific requirements of a project. The design process involves several considerations, including material selection, dimensions, and shape. Material SelectionNo single design tip can cover all the sheet metal mistakes we’ve seen, but this “best of” collection is a start. Take a look at our sheet metal design guidelines to keep you moving in the right direction. For additional help, feel free to contact a Protolabs applications engineer at 877-479-3680 or [email protected].

The purpose of custom sheet metal boxes is to offer efficient space utilization, protection for components or products, and the inclusion of additional features to enhance functionality. Importance and Benefits of Using Custom Sheet Metal Boxes. Using custom sheet metal boxes in precision fabrication projects offers several important benefits. Fabricating a sheet metal box can seem daunting, but with the right tools and techniques, it can be a straightforward process. In this article, we’ll go over the steps to fabricate a sheet metal box, including cutting, bending, and welding. Step 1: Designing the Box. Before you start fabricating your sheet metal box, you’ll need to design it.Precision Sheet Metal Box Fabrication – Tailored solutions for all your design needs. Elevate your projects with expert craftsmanship! Capabilities. . Delve into our specialized processes that breathe life into diverse sheet metal box designs. Laser Cutting – Harnessing the precision of lasers, we slice through metal, . Making enclosures, cabinets, and various types of boxes. Step bending: Used to create z-shaped profiles or other step-like forms by performing multiple bends over the same area. . Key Design Tips for Sheet Metal Enclosures. Designing sheet metal enclosures involves more than just aesthetics; it requires a deep understanding of the material .

Custom Sheet Metal Solutions Tailored to Your Needs Accurate Metal Fabricating is a high-volume METAL FABRICATION company that serves clients across North America. With a state-of-the-art facility centrally located in the Chicagoland area and unmatched expertise, find out why Accurate has earned a stellar reputation in the metal manufacturing . The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download!

The Computer-Aided Design ("CAD") files and all associated content posted to this website are created, uploaded, managed and owned by third-party users. . organization or real-world item, product, or good it may purport to portray. Sheet metal box part and assembly modeling in solidworks using Sheet metal tab Learn about the GrabCAD Platform .First, determine the dimensions and design of your sheet metal box. Sketch your design on paper, noting the length, width, and height, as well as any additional features such as mounting holes or cutouts. Be sure to account for the thickness of the sheet metal when calculating your measurements. Next, transfer your measurements onto the sheet . I have to design the packaging that goes with the products we make and it occurred to me that sheet metal and corrugated paper behave similarly. And it would be nice to design the packaging around the product and then unfold it to spec the die cut and for estimation. has any one done this or heard o. Custom sheet metal boxes: A versatile and durable solution for your needs Sheet metal boxes are a versatile and durable solution for a wide range of applications. They can be used to protect and transport sensitive .

Fusion 360 Evangelist, Taylor Stein, walks through creating parametric cardboard packaging using the new Sheet Metal tools! Download the file shown here: htt.

simple sheet metal projects

CAD design software enables engineers to create precise 3D models of custom sheet metal boxes, facilitating accurate measurements and visualizations of the final product. By leveraging CAD technology, designers can anticipate challenges and make necessary modifications early in the design phase, streamlining the production process.HVAC plenum box design. Although there are four basic types of HVAC plenum boxes, the return air plenum box is probably the most popular and may be effective as well. . Secure these panels with screws preferably with sheet metal screws. Put and secure the top panel to make it completely enclosed. Making custom design plenum box. First, attach .

Weldflow Metal Products provides high-quality sheet metal boxes and enclosures. Custom metal enclosures with powder-coated and anodized finishings are available. 1-866-848-3641- 2 - Forming Basics Press brake forming-The fundamental advantage of a press brake as a forming tool is its flexibility. By using standard vee-dies, cost savings can be realized through economical set-ups and run times on small lots and prototypes.We will make the box out of 0.032" (1/32") aluminum sheet metal. You'll want to get a 12" x 12" sheet at least. Here I'm using 6061-T6 aluminum. Feel free to experiment with different alloys. You will also need: * Left and right sheet metal shears * A spring-loaded punch * Cleco pliers and at least 18 cleco fasteners, 3/32" diameter

A simple one piece tool tray is shown being fabricated from scrap metal. The process highlights the way dimensions of the box come to life by cutting the ap.

The projection weld nut (spot weld nut) is widely used in the design of sheet metal parts. However, in many designs, the size of the pre-hole is not in accordance with the standard and cannot be accurately positioned. The structural type and dimensions are as shown in Figure 1-47 and Figure 1-48. Creating sheet metal boxes involves a series of precise steps that ensure the final product is both functional and aesthetically pleasing. This guide will take you through the process of designing, cutting, and folding sheet metal to create durable and well-fitted boxes. Step 1: Planning and Design Tools and Materials:We follow Sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. As a result, you can deliver the product at a low cost and faster timeline. It is difficult to follow all sheet metal design guidelines for complex sheet metal parts. Therefore exceptions can be there for complex sheet metal parts. Rectangular boxes are a fairly common shape for sheet metal enclosures, but other shapes can be used to best suit your needs. Shape could be driven by functionality, ease of manufacturing, space available or even purely aesthetics. . Mastering sheet metal enclosure design requires careful consideration of functional requirements, material .

architectural sheet metal fabrication supplier

Hyundai says the problem is caused by the smart junction box software logic which may not properly interpret the signals received from the multifunction switch. The same turn signal problem.

sheet metal boxes designs|sheet metal box fabrication