metal arc welding & fabrication ltd Shielded metal arc welding (SMAW), also known as manual metal arc welding (MMA or MMAW), flux shielded arc welding or informally as stick welding, is a manual arc welding process that uses a consumable electrode covered with a flux to lay the weld. An electric current, in the form of either alternating current or direct current from a Wholesale Supplier of Brass CNC Turned Parts from China. Introducing the finest range of Brass CNC Turned Parts by Dongguan K-Tek Machining Co., Ltd., a renowned manufacturer, supplier, and factory based in China.

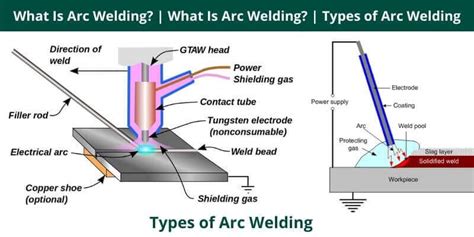

0 · types of arc welding

1 · shielded metal arc welding meaning

2 · metal arc welding diagram

3 · manual metal arc welding

4 · how to arc weld for beginners

5 · arc welding procedure step by

6 · arc welding is powered by

7 · arc welding for dummies

Production Equipments of brass turning parts: Kinds of CNC turning lathes, Automatic turning lathes, Longitudinal turning lathes, Core turning lathes. Accurate of the brass turning parts: 0.01mm.

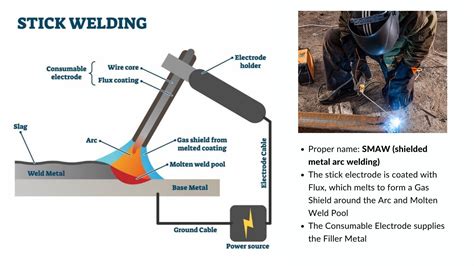

Arc welding is the process of joining metal pieces together with high heat from an arc that is generated and sustained by an electric current. The power supply can be alternating current (“AC”) or a direct current (“DC”).Arc welding is a welding process that is used to join metal to metal by using electricity to create enough heat to melt metal, and the melted metals, when cool, result in a binding of the metals. It is a type of welding that uses a welding power supply to create an electric arc between a metal stick ("electrode") and the base material to melt the metals at the point of contact. Arc welding power su.Shielded metal arc welding (SMAW), also known as manual metal arc welding (MMA or MMAW), flux shielded arc welding or informally as stick welding, is a manual arc welding process that uses a consumable electrode covered with a flux to lay the weld. An electric current, in the form of either alternating current or direct current from a

Shielded Metal Arc Welding (SMAW), commonly known as stick welding, is a pivotal manual arc welding process. It employs a consumable electrode enveloped in a flux to fuse metals together. Renowned for its versatility and . #1 Shielded Metal Arc Welding. It is also known as manual metal arc welding, flux shielded arc welding, or stick welding. In this welding, it is a process where the arc is struck between the metal rod or electrode (flux . MMA welding, conventionally known as Manual Metal Arc Welding is a dependable and candid technique to adopt. It doesn’t require a high level of experience. In this procedure, filler, parent metal, and covered flux get heated .

Learn Shielded Metal Arc Welding (SMAW) Gain the technical knowledge and skills to do Shielded Metal Arc Welding (SMAW). Also known as stick welding, SMAW is one of the simplest and most popular techniques, especially for repair and maintenance work. This is 1 of 7 credentials you can earn in welding at CLC. Dr. Dmitri Kopeliovich Shielded metal arc welding (Stick welding, Manual metal arc welding) uses a metallic consumable electrode of a proper composition for generating arc between itself and the parent work piece. The molten electrode metal fills the weld gap and joins the work pieces. This is the most popular welding process capable to produce a great variety .

Custom Welding & Fabrication shop specializes in Truck accessories and Tire Chain Hangers. Welcome to Metal Arc #6 7023 Johnstone Drive, Red Deer, Alberta T4P 0L9 Canada / Bays #8 and #9 in back . Metal Arc #6 7023 Johnstone Drive, Red Deer, Alberta T4P 0L9, Canada. 403-872-4959 [email protected]. Hours. Monday - Friday: 8am - 5:00 pm.gas metal arc welding. MIG. metal inert gas. Weld Current/Amperage. measure of electrical flow past one point. IPM. inches per minute. WFS. wire feed speed. Synergic. to work together. Oxidation. oxides from the ambient air getting into the weld pool. Buckshot. spatter on metal when welding. Tensile Strength.Students in the Gas Metal Arc Welding (GMAW) Embedded Technical Diploma develop an understanding of interpreting engineering drawings or blueprints, fundamental skills setting up and operating Gas Metal Arc Welding equipment and math functions used in a welding manufacturing environment. Students develop skills learning and applying industry .

types of arc welding

Gives arc voltage values to the control system of the feeder 7. What is an advantage of pulsed arc transfer with GMAW? Gas metal arc welding Heat input is less than spray transfer - resulting in less distortion - Used in all positions due to controlling the weld metal freeze Higher 26 to 35 arc volts Generally not as accurate 8. Recommended filters for manual metal arc welding (MMAW) are given in table 1.2. T able 1.2 – Recommended filters for MMAW For more detailed and current information refer to AS/NZS 1338.1:1992 . Gas Metal Arc Welding Handbook provides comprehensive, easy-to-understand coverage of the widely used gas metal arc welding (GMAW) process. The book presents thorough coverage of both basic skills and advanced techniques, with .MMA welding, also known as Manual Metal Arc (MMA) welding, is a type of arc welding process that involves the use of a consumable electrode to create an electric arc between the electrode and the metal workpiece. The heat from the resulting arc melts the metal workpiece and the electrode, forming a weld joint.

More. Arc welding is a type of welding that uses electricity to create a high-temperature arc to melt metal and join two pieces of metal together. It is a versatile and widely used welding process that can be used to weld a variety of metals, including steel, stainless steel, aluminum , .

Shielded Metal Arc Welding provides thorough instruction in the shielded metal arc welding process through 35 concise and easy-to-understand lessons. Each new concept is presented in a separate unit, allowing students .

Bare Metal Arc Welding: A Closer Look. Bare Metal Arc Welding, often referred to as Shielded Metal Arc Welding (SMAW), is a welding process that employs a consumable electrode coated in flux to create an electric arc. The heat generated by this arc melts both the electrode and the base metal, fusing them together as they cool. Arc welding uses a special rod that is electrically charged (an “electrode”) to join two pieces of metal together by forming an arc (or spark) in the air between them. The arc can reach temperatures over 5,432°F which gets .Set-up of Shielded Metal Arc Welding equipment on carbon steel. 3. Operate Shielded Metal Arc Welding equipment on carbon steel. 4. Demonstrate groove welds in all positions. 5. Inspection of tracks, root passes, intermediate layers, and completed welds. Learning Outcomes. 1. Recognize and demonstrate weld shop safety and the use of personal .

Arcs and Sparks: Shielded Metal Arc Welding. Recommended for use by 4-H members wanting to build, modify, or repair steel-based projects. Learn about safety, selection of equipment and materials, and fabricating techniques with shielded metal arc welding. Basic welding abilities are developed while constructing several useful projects. ©2000.The Gas Metal Arc Welding (GMAW) Technical Diploma program provides a solid foundation in process-specific production welding technology. The program is designed to develop the necessary entry-level competencies for work in the production welding and metal fabrication industries. Coursework includes all position “mig” welds on steel, stainless steel and .

Shielded metal arc welding is also known as manual metal arc welding (MMA or MMAW), flux-shielded arc welding, or stick welding. During this process, the arc is struck between the electrode flux-coated metal rod and the workpiece, and both the rod and workpiece surface melt to . 5. MIG welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining the two base materials together. A shielding gas is also sent through the welding gun and protects the weld pool from contamination. In fact, MIG stands for “Metal Inert Gas”. The technical name for it is "Gas .

shielded metal arc welding meaning

This document provides an overview of gas metal arc welding (GMAW), also known as metal inert gas (MIG) welding. It discusses the principles and process of GMAW, including the three types of metal transfer - short circuit, globular, and spray arc. The key equipment used in GMAW is described, including the welding torch, wire feed motor, power .Hobart Institute of Welding Technology 400 Trade Square E Troy, OH 45373. Toll Free: 1-800-332-9448 Fax: 937-332-9550 Bookstore Fax: 937-332-9551 Email: [email protected] this video we will discuss about What is Shielded Metal Arc welding.we will also discuss its principle of operation of this welding.Types of metal materials with a variety of welding processes; the most basic of which are, Shielded Metal Arc Welding (SMAW) also known as "stick welding” and Flux-Core Arc Welding (FCAW) also known as “wire welding.” Must pass military standard X-Ray welding test on stainless steel and copper nickel in the 6G position (restricted). The .

While shielding gas is necessary for some types of arc welding like Gas Metal Arc Welding (GMAW), others like Shielded Metal Arc Welding (SMAW) do not require it, which can reduce costs. Additionally, you’ll find the power supply and consumable electrode requirements are compatible with efficient production workflows, driving down operation .

precision machining contract manufacturer

precision ground sheet metal

Look through the wide range of wholesale wholesale cnc turning parts listings on Alibaba.com to find the right provider for your machining needs. All kinds of machining services are covered here.

metal arc welding & fabrication ltd|metal arc welding diagram