what is flange length in sheet metal It is useful for sheet metal designers as it specifies the bend radius and tooling to be used for different thicknesses. It is shown here for mild steel. Designers can use this as a guide when designing the minimum flange length possible with .

In the green kitchen below, white cabinets are paired with stainless steel appliances, resulting in a contemporary yet fresh look. The right combination of appliances and cabinets can make your kitchen look like it came straight out of a design magazine.

0 · sheet metal minimum bend length

1 · sheet metal dimensioning standards

2 · sheet metal dimensioning guidelines

3 · minimum flange length sheet metal

4 · minimum bending radius sheet metal

5 · maximum thickness sheet metal bending

6 · hole to distance sheet metal

7 · extruded hole in sheet metal

Reconnect power or plug in dishwasher. Select the proper size twist-on connectors to connect your household wiring to 16-gauge dishwasher wiring Insert wire ends into twist-on connector.

The minimum recommended sheet metal flange bend length avoid cracks in the bending area. It shall be equal to three times of sheet thickness plus bend radius. Minimum Sheet Metal Flange Bend Length = 3 x Sheet Thickness + Bend RadiusSheet metal flat length can be calculated from a part 3D CAD model using cad .

Sheet Metal gauge chart converts sheet thickness from gauge to mm or inch. .What is the minimum flange width for sheet metal? Factors like material thickness, bend radius, and application requirements typically determine minimum flange heights for sheet metal. In general, the flange height should be at least . When two edge flanges intersect, a corner is formed. At the corner, the flange lengths can either overlap, underlap, or butt. The fab shop’s main concern with corners is the sheet metal’s memory. Overbending each flange is .

It is useful for sheet metal designers as it specifies the bend radius and tooling to be used for different thicknesses. It is shown here for mild steel. Designers can use this as a guide when designing the minimum flange length possible with . In sheet metal fabrication, the flange length (or flange height) is the distance between the bend and the part’s edge or the next feature, such as a hole or another bend. If a flange is too short, the sheet metal will slip into the v .

If you require flanges shorter than the minimum acceptable flange height, Approved Sheet Metal can provide a solution. They can use the "Perfect Fit Flange Formula" to design a longer flange and then cut it down using an .

Minimum flange length on sheet metal parts must be at least 4 times the material thickness. It is recommended to use the same radii across all bends, and flange length must be at least 4 times the material thickness. Flange Length: Should be at least three times the sheet thickness to ensure stability and strength. Offset Bends: Maintain parallel planes at least two times the sheet thickness apart to avoid structural compromise.The recommended minimum flange length would be at least four times the material thickness. The limit on small flanges obtainable on the pressbrake is determined by the die opening or V-width. Small flanges approach the edge of .

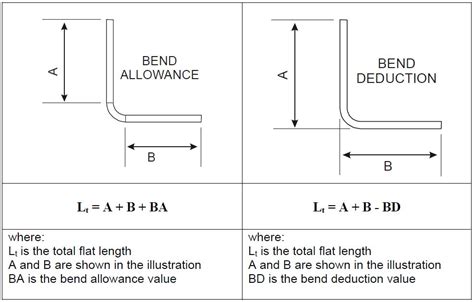

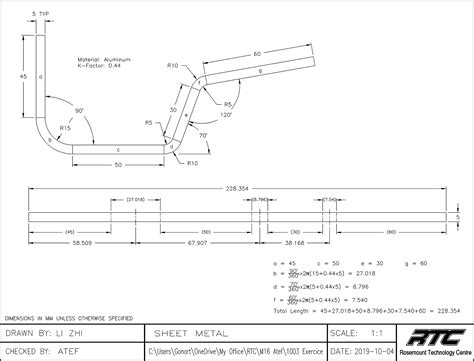

If the value of sheet metal K factor and bending flange length is known. Sheet Metal flat length can be calculated in the following three steps. Step-1: Calculate the value bend allowance for the required sheet metal bend by using the .

It is also described as the difference between the mold line length and the flange length. Also is a crucial factor in sheet metal fabrication. In a 90-degree bend, the setback value is equal to the bend radius plus the thickness . Minimum Flange Length. The first thing you need to know is the minimum flange length required for your specific part. But what is the “flange length?” Each bent part has a base flange and then the bent area. The flange . Answer: These are some great questions, covering everything from flange lengths to relief cuts. So without further ado, let’s get started. Minimum Flange Lengths. The minimum flange that can bend comfortably in any given die width is equal to 70 percent of that die width for a standard V die and about 110 percent or more of the opening for an acute die.Pro tip: You don't always need to convert to Sheet Metal. Just draw the "L" shape (2 lines) with dimensions, go to the Sheet Metal tab and click "Base Flange/Tab". You can define the material thickness, radius, extrusion length, side material is on, etc. You can even use Sheet Metal Gauge tables to expedite the design process.

What is the decimal size of 14 AWG sheet.0641. What is the name of a gage used to measure nonferrous sheet metal? Manufacturer's standard gauge for sheet metal. How is plate thickness specified. . What terms are applied to the parts of the wide flange beam represented by letters E and F.

3. Flange Length. In sheet metal fabrication, the flange length (or flange height) is the distance between the bend and the part’s edge or the next feature, such as a hole or another bend. If a flange is too short, the sheet metal will slip into the v-shaped die during forming, preventing us from bending the material.Hi guys I am designing a sheet metal wall that has a 90 degree 2" flange bend along top. The wall needs to then taper in/bend 30 degrees at about midpoint, this bend will be perpindicular (vertically across the sheet) to the top flange bend (horizontal across sheet). Explore 7 key techniques to enhance sheet metal parts' strength and durability, from material selection to advanced bending methods. +1(213) 398 9420 +86 13922902420; [email protected]; . Optimize Flange Length: Ensure the minimum flange length is appropriate for the bending process to maintain structural integrity and ease of fabrication.

Bends are the most typical feature of sheet metal parts and can be formed by a variety of methods and machines which negate the absolute need for some of the below tips. However for typical parts meant to be cost effective and easily produced the following tips should be useful. The minumum flange length is based on the die used to bend.

What is the minimum required Flange Length in Sheet metal Bending? The minimum flange length shall be equal to 4 times the sheet thickness plus the inside radius. Minimum Flange length = 4 X T (sheet thickness) + R (Inside Bend Radius)

When you create edge flanges in sheet metal parts, you can create flanges with different lengths. In the PropertyManager, you can select Multi Length Flange and specify the length of each flange in the feature. You can specify .Flange length must be at least 4 times the material thickness. . Small hole size in sheet metal requires smaller size punching tool which may leads to break during the operation. It is recommended that the diameter of the hole should be equal . A tear drop hem is a flange that has been bent more than 180 degrees. We use teardrophems for materials that lack the flexibility required of closed hems. . Forming material over .125" may cause the sheet metal to fracture. The flat length of the hem must also be a minimum of 4x the material thickness to prevent breakage. Closed hems are not .

The dimensions of the flange are based on some design parameters and standards. Some of these conditions are the following: . I'm Austin Peng. I manage a factory that specializes in CNC machining, injection molding, and sheet metal fabrication for small quantity production and rapid prototyping solutions. When I'm not immersed in work, I love .Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs. . Consider what minimum bend size you require (Only consider lines that meet your minimum bend requirement). . Minimum flange is the minimum distance that the edge of a flange, or particular types of cutouts (rounded slots parallel to the .I am new to sheet metal, and am trying to model foam as a sheet metal. I made a new rule based on steel and changed its thickness to 0.5 inches, and its k-factor to 0.0296 based on research I found. But the flanges that bend towards each .

An Air Bend Force Chart, or Force Chart breaks down a number of key components of sheet metal bending in an easy to reference format. Being able to read a bend force chart is crucial for any Brake Press operator and sheet metal engineer. The gauge, inside radius, die opening, and minimum flange length are all interconnected through different equations and relationships, the .We make test probes (rectangle with 300x100mm with 2 bends) for each material, thickness and toolset combination and then we measure all the 3 flanges dimensions and the we calculate the bend deduction by adding the 3 dimensions, subtracting the length of the probe (300mm) and dividing the result by 2 (2 bend on the probe) and then we use this . Most sheet-metal drawings I produce apply a standard drawing tolerance of +/- 0.03" and I keep most flange dimensions to 2 decimal places, so that nobody gets and grand ideas about accuracy. The angles themselves get a +/-1 degree tolerance. Considering the "hand-fit" done on most assemblies, I think Wil's point still holds.

sheet metal minimum bend length

If possible model your part in part mode, not sheet metal mode. You can then convert the part to sheet metal, in many cases this is a more efficient way to create parts in Creo. It is much faster to create the geometry in part mode for many parts. As you have found flange is not the tool that will yield the result you want in your example model.

An obround relief is the little notch at the ends of a bend that doesn’t span the entire length of a part. They allow the flange to be bent as close as possible or inside the adjacent edges of the material. . need help manufacturing sheet metal? want to post your fabrication for all to updoot? come to r/sheetmetal to discuss all things . Cleat Tool. The sheet metal fabrication shop has several options when making a rectangular flanged connection. One is to use have the flange an integral piece make from the duct, or to add a proprietary flange (#1) on to the raw end of the duct such as the below from Hardcast, a Carlisle Company. The flange is the feature created on the edge of the sheet metal by bending at a defined angle, extruding at a defined length, and offsetting out or in from the selected main sheet metal feature. To create a flange on a sheet metal: Start the “Flange” command. Home Ribbon Bar => Base Group => Flange; Menu => Insert => Bend => Flange

Determining minimum flange length is an important step in any successful bending operation. WILA recommends a flange length that is at least 6 times the material thickness. . For more information about bending short flanges or any other type of sheet metal bending on a press brake, just give us a call. We'll be happy to answer any questions .

Looking at this drawing I'd start creating the flat plate on the front or right plane, using the dimensions from the view shown on the top-right on the drawing. Adding the flanges later on. . Don't overthink it: flange commands make most sheet metal parts not too bad by themselves. Just start a sketch and do one face then keep adding flanges. Flange length. You will also need to know what flange length you’ll need and if that length will work in your chosen material. (The flange is the edge of the part that’s bent from the stationary base.) . Sheet metal bending is capable of forming many difficult parts and products, but tooling does have its limitations. There are a few .

airtight plastic electrical boxes

ak sheet metal fabrications ltd

Shop bronze plate and bronze sheet metal in a variety of alloys including commercial and phosphorous. Standard and custom cut lengths are available. UPS Rate Increases on Long Lengths!

what is flange length in sheet metal|sheet metal minimum bend length