what is gauge thickness in sheet metal Gauge (or gage) sizes are numbers that indicate the thickness of a piece of sheet metal, with a higher number referring to a thinner sheet. The equivalent thicknesses differ for each gauge size standard, which were developed based on the weight of the sheet for a given material. CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or Computer Aided Design (CAD) software like .CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, known as the blank or .

0 · steel sheet gauge size chart

1 · steel gauge to thickness chart

2 · steel gauge thickness chart inches

3 · sheet metal thickness gauge chart

4 · sheet metal screw gauge chart

5 · sheet metal gauge range chart

6 · metal plate gauge thickness chart

7 · metal gauge size chart

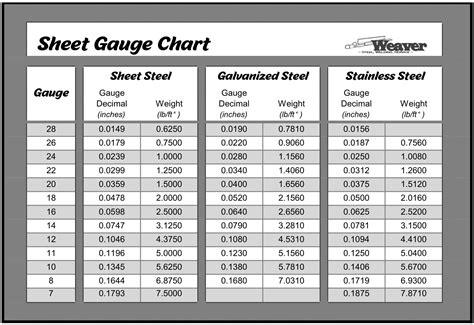

Gauge size chart for sheet metal. Filter for standard steel, galvanized steel, stainless steel, zinc, or birmingham gage.

Gauge (or gage) sizes are numbers that indicate the thickness of a piece of sheet metal, with a higher number referring to a thinner sheet. The equivalent thicknesses differ for each gauge size standard, which were developed based on the weight of the sheet for a given material.Pure metal / Used as an alloy element for aluminum, lead, zinc, and other . When working with sheet metal, the term “gauge” is often used. Gauge are used to .

A sheet metal gauge tool is used to measure metal thickness and shows both the gauge number as well as the thickness of the metal in thousandths of an inch. Gauge thickness applies differently depending on the .

Sheet metal gauge refers to a standardized method used to measure and categorize the thickness of sheet metal. This system, which has its roots in the British iron wire . The term "gauge steel" is often used to refer to the thickness of sheet metal made of steel. Understanding these nuanced differences is vital when consulting a metal gauge chart to ensure that you're selecting the appropriate . The sheet metal gauge system helps determine the thickness or diameter of different materials, such as metal and wire, based on their weight. Gauge is sometimes called “gage,” often denoted by a number followed by .

A gauge conversion chart can be used to determine the actual thickness of sheet metal in inches or millimeters. For example, 18 gauge steel, according to a gauge conversion chart, is 0.0478 inch or 1.214 millimeter. Sheet metal thickness is denoted by gauge, sometimes spelled gage, which indicates a standard thickness before processing. Click here for a Gauge to mm Conversion Chart. .A sheet metal gauge chart, also known as a sheet metal gauge table or sheet metal thickness chart, is a reference tool that provides a standardized measurement system for sheet metal thickness. It offers a comparison .Mild steel sheet. 18 or 20 or 22 gauge. About for a 4'*4' piece. 22 gauge for new Hondas. 18 for old vw pans. 20 gauge for old vw bodies. It's a personal preference. 22 is way easier to bend than 18, but 18 will take more weld .

Gauge numbers inversely correlate with sheet metal thickness: as the gauge number increases, the metal thickness decreases. For instance, 8-gauge sheet metal is substantially thicker than 16-gauge. It’s crucial to .

steel sheet gauge size chart

In most of the world, sheet metal thickness is consistently specified in millimeters. In the U.S., the thickness of sheet metal is commonly specified by a traditional, non-linear measure known as its gauge. The larger the gauge number, the . Sheet metal thickness? Jump to Latest . I find that 19 gauge is a bit stiff to work with for general body work. I use 18 for floor panels, 20 for areas where a bit of extra stiffness is desireable, like fenders, and 22 to 24 for general body work. The pre-fab body panels you can order are made from 22 to 24 gauge satin coated steel.

dewalt sheetrock cutter with plastic electric boxes

Thank you for the readouts on the thickness of your pieces, I'm making up my own chart for the future. I recognize that thickness alone is not the determining factor, but there is a huge difference in strength and quality between 18-20 gauge and I want the thickest I can get. Sauron, what nuts are you referring to?-shoe Sheet Steel Gauge Standards. See our article “Sheet Steel: Gauge, Thickness, and Weight Chart” for information on the Manufacturers Standard Gauge, which is used commercially in the US, having replaced the US Standard Gauge over time.. In the United States, the standard (thickness) gauge for sheet steel is established by federal law. 15 U.S. Code § 206 states, “For .Sheet Metal Knowledge Menu . The following sheet metal gauge size reference chart gives the weight and thickness of sheet metal given as a "gauge" (sometimes spelled gage) and indicates the standard thickness of sheet metal and wire.For most materials, as the gauge number increases, the material thickness decreases.

Sheet metal thickness is measured in gauges; the higher the number, the thinner the sheet metal. The most commonly-used sheet metal sizes range from 26 gauge (thinner) to 7 gauge (thicker). A sheet metal gauge tool is used to measure metal thickness and shows both the gauge number as well as the thickness of the metal in thousandths of an inch.0.063" as a flat sheet is stiff, but as soon as a bend or curve is applied to 0.040", it's very rigid. 2024T3 is a pretty malleable alloy but you can get a pretty rigid structure out to about 18" with a simple bend. There's a reason it's the go-to thickness/alloy for aircraft structures.The sheet metal gauge chart serves as a vital resource for professionals in the sheet metal industry, offering insights into the appropriate thickness for different materials. By understanding and utilizing the gauge chart effectively, manufacturers and designers can create high-quality products that meet industry standards and customer .

steel gauge to thickness chart

What thickness or gauge is standard automotive sheetmetal on American vehicles, such as a door skin or fender skin. I'm practicing up on my Mig and am trying to determine settings, using ER70-6S and C25. The tables in my texts and on the machine reference gauge. Thanks for any info. Sheet Metal Thickness. Jump to Latest . What is the average gauge of sheet metal used for restorations because I can get a Lincoln welder that welds up to 1/4" sheet metal and I was wondering if that is going to get the job done or would I need to bump up to a welder capable of welding 5/16'' sheet metal.

Sheet metal parts are no different, and we can easily create configurations with different lengths, bend angles, cutouts, etc. But what if you want to create configurations with different sheet metal gauge values? “Thickness” is an automatically generated Global Variable in SOLIDWORKS sheet metal parts. The variable itself can’t be . Hi modockid, Sheet Metal Thickness (Gauge) Chart in Inches Gauge Mild Steel Aluminum Galvanized Steel Stainless Steel 3 0.2391 0.2294 0.25

It really isn't enough thickness to worry about with settings though, and a cheap HF flux core welder won't allow you to dial in the difference between (for example), 20 gauge and 22 gauge anyways. That welder is not meant to weld thin sheet metal in .

A metal gauge thickness chart is a visual representation that shows the different gauges of metals along with their corresponding thickness measurements. The concept of ‘gauge’ refers to the standard measurement used to quantify the thickness of sheet metal; however, it can be somewhat confusing as lower gauge numbers indicate thicker .I work in product design and create sheet metal parts on a semi-regular basis. I recently learned about the origins of the Gauge/Gage system in defining wire and sheet thickness. . As a machinist, the times where I've seen the gauge thickness actually matter is when it is called out in the notes and specified a tolerance. Or some thing like .

Sheet metal is a versatile material widely used in various industries, including automotive, aerospace, construction, and electronics. When designing sheet metal parts, understanding the concept of gauge thickness is essential for creating accurate 3D models and ensuring the manufacturability of the final product. Hello, I am going to replace a large portion of my firewall and I was wanting to know what gauge sheet metal to go with? The reason I am replacing it is to smooth it out, the factory firewall has all sorts of holes for AC and Heater and wiring harness. So what would yall recomend? OH and this is for a 1970 Mustang coupe. Thanks in advance Corey

what thickness metal needed to repair frame rail. Jump to Latest . Checked the frame rail thickness Its 16 gauge . . el cheapo sheet metal break . Save Share Reply Quote Like. This is an older thread, you may not receive a response, and could be reviving an old thread. .

steel gauge thickness chart inches

SHEET METAL Thickness -- RT-108. These questions pop up periodically, so I have this page dedicated to a seemingly trivial item. The short answer is, all MGA body sheet metal is 18 gauge, 0.048-in thick, 2-lb per square foot, and all MGA frame sheet metal is 14 gauge, 0.075-in thick, 3-lb 2-oz per square foot (including the round tubing). . The sheet metal up by the front grill and by the trunk lip measures at 0.050" on my car. That puts it at 18 gauge both sides painted. The circular opening under the trunk were 0.041" or 19 gauge, both sides painted. I just welded on my .

I disagree, almost all the sheet metal on a 55-57 is 18 gauge, or about .048" thick. Patch panels will be less, many will be 20 gauge, about .036" thick, and 22 gauge is .030" thick. Any time I wanted to use the spot welders at the tool n die shop I worked at during the 1980s when I miced the thickness it was usually right at .050 thick. To guard against people accidentally putting a hand into a machine, I’d use 1.5mm steel. If the metal is much thinner than this it may be difficult to weld or may distort in use. If the metal is much thicker than this it may be too heavy and unnecessarily expensive. If the guard is large, it may need thicker metal as it may distort as it is .

Understanding this system helps professionals select the right type of sheet metal for their specific needs. How to Read a Metal Gauge Thickness Chart. To effectively read a metal gauge thickness chart, one must first recognize that different materials have their own unique charts due to variations in density and composition. Most charts list .

Gauge Numbers: Gauge numbers typically range from 0 to 36, although the commonly used range for sheet metal is between 7 and 30.As the gauge number increases, the thickness of the metal decreases. For example, a sheet metal with a gauge of 18 is .

di2 junction box in stem

di2 junction box weight

Find the proper measurement for your gauge size. This chart compares gage numbers to their steel and aluminum sizing standards.

what is gauge thickness in sheet metal|sheet metal gauge range chart