bending 22 gauge sheet metal Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make . The Best Tool Chests. Best Overall: Milwaukee Heavy Duty Tool Storage Tool Chest Combo; Best Value: Tankstorm Heavy Duty Rolling Tool Cart; Best Workspace Combo: Husky 9-Drawer.

0 · sheet metal bending techniques

1 · sheet metal bend size

2 · sheet metal bend chart

3 · sheet metal bend calculator

4 · sheet metal bend allowance

5 · how to bend 24 gauge metal

6 · bending sheet metal

7 · 24 gauge sheet metal bend

Sigma's weatherproof two-gang boxes provide a junction for conduits and can house up to two wired devices such as a receptacle or switch. The rugged, die-cast construction prevents moisture penetration making the boxes suitable for wet, damp or dry locations.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. See more Learn how to use a straight handle hand seamer to bend sheet metal. Learn about- -Sheet metal gauges -Types of hand seamers Sign up for the email list. Grab some great tools and. To bend sheet metals into accurate, clean, and professional-looking bends, the metal structure requires going through multiple bending processes depending on the weight, tensile strength, and other properties of the metal . How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.-----.

Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make . Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.

Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are more malleable than others. That means that some will bend, whereas others will .

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. Learn how to use a straight handle hand seamer to bend sheet metal. Learn about- -Sheet metal gauges -Types of hand seamers Sign up for the email list. Grab some great tools and. To bend sheet metals into accurate, clean, and professional-looking bends, the metal structure requires going through multiple bending processes depending on the weight, tensile strength, and other properties of the metal structure. How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.-----.

Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are more malleable than others. That means that some will bend, whereas others will weaken and crack. An overview of minimum bend radii and bend orientation for sheet metal bending. Learn about how you can make better bent sheet metal parts.

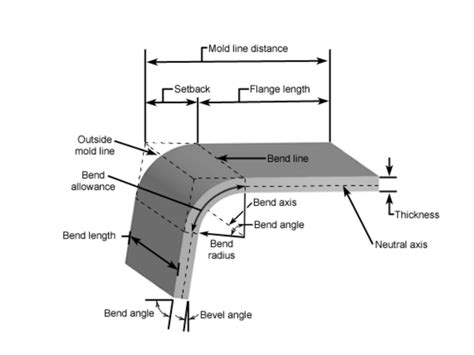

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at .

Similar to wire, sheet metal thickness is measured in gauges, with a higher number indicating a thinner sheet. To measure the thickness, you can use a sheet metal gauge, which will show you thickness in both gauge number and thousandths of an inch. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. Learn how to use a straight handle hand seamer to bend sheet metal. Learn about- -Sheet metal gauges -Types of hand seamers Sign up for the email list. Grab some great tools and. To bend sheet metals into accurate, clean, and professional-looking bends, the metal structure requires going through multiple bending processes depending on the weight, tensile strength, and other properties of the metal structure.

How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.-----.Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are more malleable than others. That means that some will bend, whereas others will weaken and crack.

An overview of minimum bend radii and bend orientation for sheet metal bending. Learn about how you can make better bent sheet metal parts. Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at .

metal building box gutters san antonio

sheet metal bending techniques

sheet metal bend size

This RAB Lighting VXCW white weatherproof round box is made of die cast aluminum for resistance to corrosion and is suitable for use in wet locations. It has a green washer-head ground screw in a pre-tapped hole, and it comes with a 1/8" thick closed cell foam rubber gasket for protection from weather.

bending 22 gauge sheet metal|sheet metal bend calculator