cost effective sheet metal laser cutting Upload your STEP file for an instant laser cutting quote using our intuitive online platform. Quote in seconds, order in minutes, receive parts in days. Unistrut mounted either vertically or horizontally will work fine. I use 3/8" hex nuts, bolts and 3/8" x 1-1/4" fender washers to mount the unistrut to the metal sheathing. Fender washers inside and out.

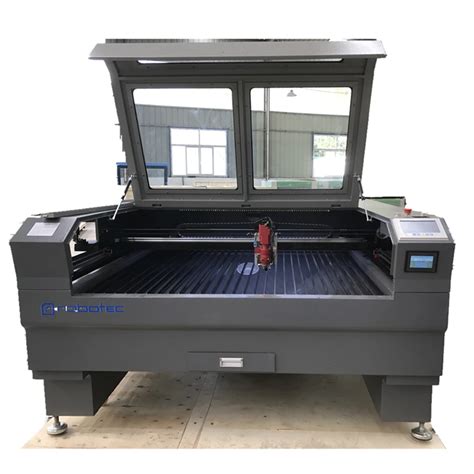

0 · small laser metal cutting machine

1 · small laser cutter for metal

2 · sheet metal laser cutter price

3 · metal laser cutter machine price

4 · laser cutter price list

5 · industrial metal laser cutting machine

6 · hobby metal laser cnc cutter

7 · 20mm metal laser cutting machine

The main difference between unfinished and prefinished cabinets is that unfinished cabinets are sold without any stain, paint, or finish, offering customization but requiring extra work to complete. In contrast, pre-finished .

Laser cutters produce metal parts from sheet material using a laser beam to vaporize sections of the workpiece. eMachineShop offers a cost-effective cutting solution whether you need a single part, batch of prototypes, or a production order. 50+ Materials. FREE Shipping in the USA. . Is laser-cutting cost-effective compared to other cutting methods? Laser-cutting is highly cost-effective due to its precision, minimal material wastage, and reduced setup time compared to other cutting methods like .

Laser cutting is a versatile sheet metal fabrication process that creates precise cuts with minimal material waste—but it can be expensive. A .Upload your STEP file for an instant laser cutting quote using our intuitive online platform. Quote in seconds, order in minutes, receive parts in days. Question: How can laser cutting in sheet metal fabrication be cost-effective? Answer: Laser cutting is cost-effective due to its high speed and efficiency in producing accurate cuts, reducing material waste.Experts in sheet metal laser cutting. Get instant online quotes, next-day delivery, and top-quality parts. Turn CAD designs into real products.

Iron sheet laser cutting represents the pinnacle of cost-effective metalworking solutions. Its precision, efficiency, flexibility, and environmental benefits empower .

Sheet metal laser cutting is a fabrication process that uses a high-powered laser beam to precisely cut or engrave metal sheets. Controlled by a CNC system, the laser emits a focused beam of light that heats and melts the metal at targeted .

The cost of sheet metal laser cutting depends on various factors including material type, thickness, complexity of the design, production volume, and machine time. For a bespoke sheet metal laser cutting quote, get in touch with .Explore factors affecting "How much should laser cutting cost?" including laser types, material strength, and outsourcing vs in-house operations.Laser cutters produce metal parts from sheet material using a laser beam to vaporize sections of the workpiece. eMachineShop offers a cost-effective cutting solution whether you need a single part, batch of prototypes, or a production order. 50+ Materials. FREE Shipping in the USA. 100% Quality Guaranteed.

Is laser-cutting cost-effective compared to other cutting methods? Laser-cutting is highly cost-effective due to its precision, minimal material wastage, and reduced setup time compared to other cutting methods like plasma cutting. Conclusion Laser cutting is a versatile sheet metal fabrication process that creates precise cuts with minimal material waste—but it can be expensive. A number of factors contribute to the cost of laser cutting services, from material thickness to the complexity of a part’s features.

Upload your STEP file for an instant laser cutting quote using our intuitive online platform. Quote in seconds, order in minutes, receive parts in days.

Question: How can laser cutting in sheet metal fabrication be cost-effective? Answer: Laser cutting is cost-effective due to its high speed and efficiency in producing accurate cuts, reducing material waste.Experts in sheet metal laser cutting. Get instant online quotes, next-day delivery, and top-quality parts. Turn CAD designs into real products.

Iron sheet laser cutting represents the pinnacle of cost-effective metalworking solutions. Its precision, efficiency, flexibility, and environmental benefits empower manufacturers to optimize productivity, reduce costs, and stay competitive in today’s demanding market.Sheet metal laser cutting is a fabrication process that uses a high-powered laser beam to precisely cut or engrave metal sheets. Controlled by a CNC system, the laser emits a focused beam of light that heats and melts the metal at targeted locations, allowing for .

The cost of sheet metal laser cutting depends on various factors including material type, thickness, complexity of the design, production volume, and machine time. For a bespoke sheet metal laser cutting quote, get in touch with the experts at The Laser Cutting Co.

small laser metal cutting machine

custom electrical enclosures az

custom house numbers metal

For a timeless look, explore our collection of decorative metal shelf brackets. Featuring traditional designs, these brackets add a touch of sophistication to any space. They are the perfect choice for those seeking elegant style and reliable support for their shelves.

cost effective sheet metal laser cutting|small laser cutter for metal