what is sheet metal parts What Is Sheet Metal Forming? Sheet metal forming entails taking thin, flat sheets of metal and manipulating them into fully formed 3D structures. The process transforms a basic raw material into complex finished products .

Midwest Metal Fabricators, Ltd is located at 712 Maple St in Wapakoneta and has been in the business of Sheet Metalwork since 2001.

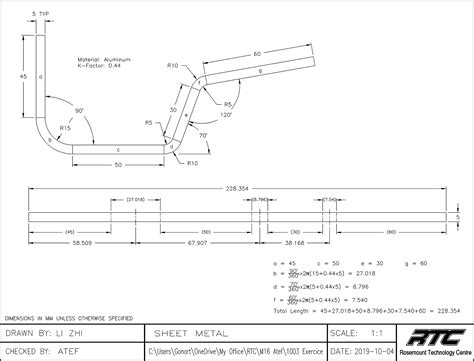

0 · solidworks convert to sheet metal

1 · sheet metal parts near me

2 · sheet metal dimensioning standards

3 · automotive sheet metal near me

4 · aftermarket sheet metal parts

5 · aftermarket sheet metal car parts

6 · aftermarket sheet metal body parts

7 · aftermarket auto sheet metal parts

Once a wire type is determined for your welding equipment, two additional pieces of information are needed in order to purchase this consumable. The first is the wire diameter, which is usually given in thousands of an inch. The most .

Sheet metal is an industrial process that forms thin, flat pieces of metal, such as steel and tin, into coils. In the U.S., the thickness of sheet metal is typically specified by its gauge, which ranges .Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with .

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different .

landscaping electrical boxes

Learn about the critical factors to consider when selecting a material for your sheet metal parts: types, application, physical properties, finishing, and cost. Sheet metal parts are thin, flat pieces of metal that undergo various fabrication processes to achieve specific shapes and sizes. These processes primarily involve cutting,. What Is Sheet Metal Forming? Sheet metal forming entails taking thin, flat sheets of metal and manipulating them into fully formed 3D structures. The process transforms a basic raw material into complex finished products .Basic Principles. Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and .

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques.

solidworks convert to sheet metal

After the tool design is completed, the specialized tooling (such as blanking dies, forming dies, and piercing dies), is fabricated using a variety of machining tools and technology. The tool and die design must ensure proper material flow, . Drawing is a sheet metalworking operation used to produce cup-shaped or box-shaped, or other complex-curved, hollow parts. Drawing is accomplished by placing a piece of sheet metal over a die cavity and then using a punch to push the metal into the cavity.

What Is Sheet Metal Parts? Sheet metal parts are models in sheet form that can vary in size, shape, and material. Sheet metal parts are often uniform in thickness and are easily modified by adding features such as chamfers, holes, and flanges. The material used to create sheet metal parts is malleable, making them suitable for complex and .Parts made from sheet metal must maintain a consistent thickness for best results. Related: 1. What is Ferrous Metal? 2. What is Non-Ferrous Metal? Many different metals can be used in sheet metal manufacturing such as aluminum, brass, copper, steel, tin, nickel, and titanium. Some important sheets for decorative purposes include silver, gold .

Sheet metal stamping process flow diagram, metal stamping is a cold-forming process, which uses a special tooling system and force to transform sheet metal into useful parts. The special tools may include dies, or stamping presses to form sheet metal parts.

Knowing how to inspect sheet metal parts can help you better communicate with your metal parts suppliers and foster a stronger, more collaborative relationship. With that in mind, let’s dive deeper into the types of inspection that are normally involved in the metal manufacturing process and how you can help set your project up for success.Sheet metal is a versatile material used in various applications, including automotive parts, greenhouse equipment, buckets, irrigation pipe . Photochemical machining is an extremely precise and cost-effective method for creating sheet metal parts. It uses controlled corrosion to create a smooth finish, utilizing a photoresist and an etchant. .

Right click on a body and Export to DXF/DWG (or save as and change the file type to DXF or DWG). Save the initial file, but then in the DXF/DWG Output dialog change the export type to Sheet Metal and select all of the sheet metal bodies. Choose which entities you want to export and select "Separate Files" at the bottom.

Surface Finish for Sheet Metal Parts. Surface treatment is also the basics of sheet metal fabrication you need to understand.Surface finish is an essential consideration in the process of sheet metal fabrication. There are some methods of .Sheets of Nirosta stainless steel cover the Chrysler Building. Microscopic close-up of mild steel sheet metal. Sheet metal is metal formed into thin, flat pieces, usually by an industrial process.. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. CNC metal cutting transforms raw metal stock into finished parts through controlled material removal. The process relies on specialized cutting tools that follow precise, computer-guided paths. . It works exceptionally well for sheet metal and thin materials. Water Jet Cutting: Advantages and Applications.

Sheet metal bending involves shaping a metal sheet into a desired form or angle by applying force at a specific point, resulting in a permanent bend or curve. . bending machines, are used in this process. It is commonly used in manufacturing industries to create HVAC ductwork, metal enclosures, and automotive parts. Additionally, the bending . With sheet metal forming, you are certain of achieving precisely-cut metal parts with limited material waste. This process supports manufacturing of everyday products, from household appliances to structural components in buildings, but you need to make sure it’s the right application for your project, so you don’t run into roadblocks.

l&l metal fabrication birmingham

Sheet metal forming is a process used in many industries to make metal parts from thin metal sheets. It’s actually one of Xometry's most popular manufacturing methods. Our customers use the Xometry Instant Quoting Engine® to get automatic quotes on everything from simple brackets to aircraft parts and sheet metal assemblies. The intricacy level of the design directly impacts the overall expense. Designs that feature intricate, small metal parts or complex sheet metal structures can escalate labor costs due to the added precision and time .Study with Quizlet and memorize flashcards containing terms like Identify the three basic types of sheet metalworking operations, In conventional sheet metalworking operations (a). what is the name of the tooling and (b) what is the name of the machine tool used in the operations?, In blanking of a circular sheet metal part, is the clearance applied to the punch diameter or the .Hi u/Jadas922, . You are in "Flat Pattern" mode for sheet metal. Creating sheet metal features is not appropriate in that mode so they are grayed out. Clicking the button in the top right of the viewport will bring you back out of this to the .

There were loads of simple sheet metal parts all over the machine, covering this and that. Our supplier has already been working with us for decades at that point, so all we really did was the exterior dimensions of the sheet metal, and the call-outs for thru/countersunk holes. We never specified the bend radius, simply shaved down the milled . When fabricating sheet metal parts for the aerospace industry, you must choose the right technology and material besides working with a trusted company. It is the surest way to get dimensionally accurate, precise, and durable aircraft parts and components.

sheet metal parts near me

sheet metal dimensioning standards

The individual sheet metal parts are inserted into the weldment part. However, if the weldment contains extrusions then those compoments are all created inside the weldment due to the ease of generating a cut list, creating paths using 3-D sketches, and . Sheet metal deep drawn parts. Size Calculation. You can assume that the blank size of deep drawn sheet metal equals the blank surface area of the finished part. You can calculate the deep-drawn sheet metal blank size by following these steps: Step 1: Surface Area Calculation. Surface Area of Blank. Step 2: Finish Part Surface area calculation I've inherited a multibody part for detailing, yet it's in sheet metal. Adding to that, this is also an iPart. What I would like to do is break out each of the bodies, as if they're separate components, yet am uncertain what that workflow is or if it can be done. The items as individual components would clarify things for the manufacturing group. To achieve the best surface finish possible for sheet metal fabricated parts, we recommend sourcing a material that already has a surface finish comparable to the desired finish.Then, we can use one of these standard methods to clean it up even further: Employing our Timesaver Abrasive Belt Finishing Machine to clean up the surfaces of sheet metal fabricated .

l shaped metal shelf brackets

5. • Aluminum is also a popular metal used in sheet metal due to its flexibility, light weight, and cost effectiveness • Most common Grade 3003- H14 is fairly strong, while maintaining the same formability and low cost. It is corrosion resistant and weldable. It is often used in stampings, spun and drawn parts, and fan blades • Brass is an alloy of copper, which is widely .Sheet metal stamping is a core part of Shengen’s expertise. We hold this process dear to our hearts, and I would like to share it with you its essence today. Basic Definition and Terms Sheet Metal Stamping: Unpacking the term. Cold-forming is the process of sheet metal stamping. Cold-forming is the process of shaping metal using pressure . With some metal products that are comprised two sheet metal parts, one metal part that corrodes more quickly is deliberately introduced in order to protect the other sheet metal part. A good example of this is with zinc coated and galvanized dipped metal parts. If a zinc coating is applied to steel, the zinc will take on the sacrificial anode .

The appropriate metal sheet is selected based on the part’s requirements, such as strength, durability and corrosion resistance. Other factors considered are the part’s intended use, operating environment and cost constraints. Choosing the right material is essential for achieving the desired performance and the longevity of the stamped part.

automotive sheet metal near me

Understanding the Stick Welding and Its Benefits for Sheet Metal. Stick welding, also known as shielded metal arc welding (SMAW), is a versatile and widely used welding process that involves the use of an electrode coated in flux to join metals.

what is sheet metal parts|aftermarket sheet metal parts