5 axis cnc machine design Among them, the 5-axis CNC machine stands out as a transformative tool, granting unparalleled precision and flexibility in complex machining tasks. By providing movement along five different axes . When working with sheet metal, the term “gauge” is often used. Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system.

0 · haas 5 axis cnc machine for sale

1 · affordable 5 axis cnc machine

2 · 5 axis cnc milling machine for sale

3 · 5 axis cnc machine specifications

4 · 5 axis cnc machine price uk

5 · 5 axis cnc machine manufacturers

6 · 5 axis cnc machine hobby

7 · 5 axis cnc machine for sale

When it comes to auto body repair, the choice of sheet metal gauge is important for ensuring structural integrity and performance. For aluminum panels, gauges typically range from 14 to 20, with lower numbers indicating thicker sheets.

haas 5 axis cnc machine for sale

cnc machining lonsdale

affordable 5 axis cnc machine

5-axis CNC machines come in various configurations, each with its own strengths and weaknesses. Let’s explore the main types: Table-table, Head-table, and Head-head configurations, focusing on the Trunnion and Swivel head designs, .Regardless of a particular original equipment manufacturer machine tool builder, there are several common configurations for 5-axis CNC machines that are available. Each one has its own set of strengths that make it stand out among . 5-axis CNC machining leverages advanced computer numerical control (CNC) technology to orchestrate precise, simultaneous movements along five distinct axes. This .

A 5-axis CNC machine allows the machining of five different surfaces simultaneously. This dynamic movement grants the machine unparalleled freedom to approach the workpiece from any angle, making it . Among them, the 5-axis CNC machine stands out as a transformative tool, granting unparalleled precision and flexibility in complex machining tasks. By providing movement along five different axes . 5 axis CNC machining uses a machine that can simultaneously move and rotate in five axes to machine a part. Its benefits include its high suitability for fabricating parts with complex designs and intricate details, .

What started as a high-end machining technique focused on machining complex shapes has now transitioned to a nearly industry standard technology to optimize the CNC .5-axis machining is a specific type of CNC machining that enhances the traditional 3-axis approach. This electromechanical process controls tools across five axes with high accuracy and precision to cut away excess material and .

cnc machining lincoln ne

5-axis CNC machines come in various configurations, each with its own strengths and weaknesses. Let’s explore the main types: Table-table, Head-table, and Head-head configurations, focusing on the Trunnion and Swivel head designs, as well as the Traveling Column 5-Axis Machining Center. Full 5-axis CNC machining means a machine’s processing ability to move a tool or a workpiece in five different axes simultaneously. 5-axis CNC machining is considered a more evolved and sophisticated version of the CNC machining process.Regardless of a particular original equipment manufacturer machine tool builder, there are several common configurations for 5-axis CNC machines that are available. Each one has its own set of strengths that make it stand out among the choices. 5-axis CNC machining leverages advanced computer numerical control (CNC) technology to orchestrate precise, simultaneous movements along five distinct axes. This sophisticated control system enables the machining of complex geometries with unprecedented flexibility and efficiency.

A 5-axis CNC machine allows the machining of five different surfaces simultaneously. This dynamic movement grants the machine unparalleled freedom to approach the workpiece from any angle, making it ideal for producing intricate and complex geometries with exceptional precision. Among them, the 5-axis CNC machine stands out as a transformative tool, granting unparalleled precision and flexibility in complex machining tasks. By providing movement along five different axes simultaneously, it transcends the capabilities of . 5 axis CNC machining uses a machine that can simultaneously move and rotate in five axes to machine a part. Its benefits include its high suitability for fabricating parts with complex designs and intricate details, accuracy, speed, and production efficiency.

What started as a high-end machining technique focused on machining complex shapes has now transitioned to a nearly industry standard technology to optimize the CNC Milling industry. 5-axis machining has veritably reinvented how we think about milling parts.

5-axis machining is a specific type of CNC machining that enhances the traditional 3-axis approach. This electromechanical process controls tools across five axes with high accuracy and precision to cut away excess material and produce components and parts.

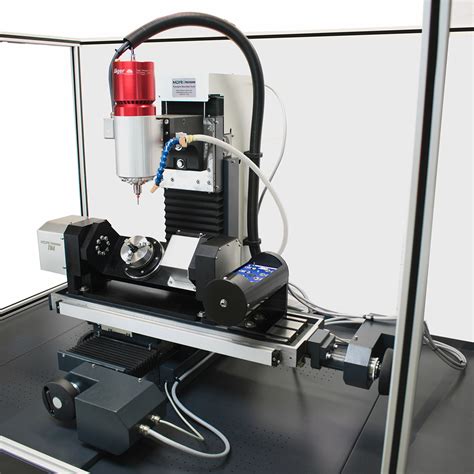

Overview of the dedicated 5-axis machining configurations. Focusing on the Swivel head, trunnion table, and travelling column 5-axis CNC machines

5-axis CNC machines come in various configurations, each with its own strengths and weaknesses. Let’s explore the main types: Table-table, Head-table, and Head-head configurations, focusing on the Trunnion and Swivel head designs, as well as the Traveling Column 5-Axis Machining Center.

Full 5-axis CNC machining means a machine’s processing ability to move a tool or a workpiece in five different axes simultaneously. 5-axis CNC machining is considered a more evolved and sophisticated version of the CNC machining process.Regardless of a particular original equipment manufacturer machine tool builder, there are several common configurations for 5-axis CNC machines that are available. Each one has its own set of strengths that make it stand out among the choices. 5-axis CNC machining leverages advanced computer numerical control (CNC) technology to orchestrate precise, simultaneous movements along five distinct axes. This sophisticated control system enables the machining of complex geometries with unprecedented flexibility and efficiency. A 5-axis CNC machine allows the machining of five different surfaces simultaneously. This dynamic movement grants the machine unparalleled freedom to approach the workpiece from any angle, making it ideal for producing intricate and complex geometries with exceptional precision.

Among them, the 5-axis CNC machine stands out as a transformative tool, granting unparalleled precision and flexibility in complex machining tasks. By providing movement along five different axes simultaneously, it transcends the capabilities of .

5 axis CNC machining uses a machine that can simultaneously move and rotate in five axes to machine a part. Its benefits include its high suitability for fabricating parts with complex designs and intricate details, accuracy, speed, and production efficiency. What started as a high-end machining technique focused on machining complex shapes has now transitioned to a nearly industry standard technology to optimize the CNC Milling industry. 5-axis machining has veritably reinvented how we think about milling parts.5-axis machining is a specific type of CNC machining that enhances the traditional 3-axis approach. This electromechanical process controls tools across five axes with high accuracy and precision to cut away excess material and produce components and parts.

CNC stands for “Computer Numerical Control”, and refers to a manufacturing method based on the automation and precise control of machine tool movements through the use of pre-programmed computer software integrated into these tools.

5 axis cnc machine design|haas 5 axis cnc machine for sale