sheet metal corner joints Learn how sheet metal joints are made and used in the HVAC sheet metal industry to make air conditioning ductwork. Choose from our selection of welding clamps, including plier clamps, hold-down toggle clamps, and more. In stock and ready to ship.

0 · types of sheet metal seams

1 · sheet metal seams pdf

2 · sheet metal overlap joint

3 · interlocking sheet metal joints

4 · interlocking sheet metal design

5 · inside corner joint welding

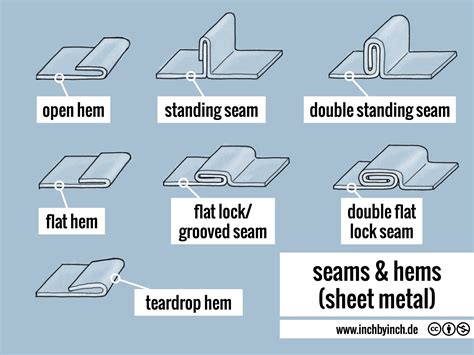

6 · grooved seam sheet metal

7 · corner weld called

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

types of sheet metal seams

Corner Joint Welding is a process of joining two parts at a 90-Degree angle (right angle), making an L-Shape joint. This type of welding is commonly used to join metal sheets .The GROOVED SEAM JOINT (fig. 2-57) is one of the most widely used methods for joining light- and medium-gauge sheet metal. It consists of two folded edges that are locked together with a . Typically used on aluminum parts over 0.40” thick, open corner joints can be welded using several methods: fillet/seam, fuse, tack, or stitch .

Welding a corner joint secures two metal pieces at a 90-degree angle. This guide will teach you the various types of corner joints and tips for each project type. Learn how sheet metal joints are made and used in the HVAC sheet metal industry to make air conditioning ductwork.

8 foot sheet metal

The sheet metal bodies can be split up to individual sheet metal components and they can be joined to other components. However, only the moldings on the left and right side of the box can have a joint origin point at .(Image source) In panel construction, if visible from the outside, the most often encountered problem is clean corner joints. A miter joint is the most widely practiced joint because it is the fastest way. A welded corner joint always has .

When a sheet metal model is active (in the process of being created or edited), additional tools are available: Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Tab - Add a tab to a sheet metal flange.; Make joint - Convert the intersection of two walls into a joint feature, either a bend (walls joined by cylindrical geometry) . Corner joints create a corner between pieces of metal. They can be further broken down into open and closed options. Open corner joints refer to when the pieces of metal don't sit flush together, and the space between the two need to be filled in with filler metal during the welding process.Another joint type in sheet metal work is the flush corner joint. A flush corner joint is only used on lighter sheet metal (12 gauge or lower). The reason for this is because getting good penetration is challenging and it cannot handle significant loads.

This guide will teach you the various types of corner joints and tips for each project type. An Airgas Company. 1-866-733-3272. Customer Access Portal; Find a Location; . (but not too much) and pressure can be very hard. Mistakes can leave gaps in the weld, cause undue stress on the metal, or leave a weak joint behind. Con: Because of the . Edge joints and corner joints have many similarities. A corner joint is typically the outside of the workpieces, while an edge joint can be on the inside of the workpiece. . When welding a lap joint on thinner materials like sheet metal, reduce your amperage and use a faster travel speed to avoid distortion and burn-through.Choose from our selection of sheet metal corners, including multipurpose aluminum, stainless steel, and more. In stock and ready to ship. BROWSE CATALOG. Abrading & Polishing; . Shield corners on walls and other surfaces from impact. 26 products. Wall Bases. Protect the bottom of walls from foot traffic and impact. 2 products.A corner joint in welding refers to a joint where two pieces of metal meet at a 90-degree angle. Corner joints fundamentally consist of two types: Open Corner Joints: In an open corner joint, the two pieces of metal meet at their edges, forming a V-shaped gap. This requires a larger weld deposit to fill the gap.

Selection of the type of sheet metal joint has an impact on product design, manufacturing cost, assembly process, joint reliability, and performance. The following factors affect the selection of the sheet metal joining process. Required joint type: permanent or .

Closed corner joints involve the two metal pieces meeting at right angles, resulting in a closed appearance. Half-open corner joints, on the other hand, . This type of joint is commonly utilized in sheet metal fabrication to construct various components such as frames, boxes, and other applications. By welding the materials together at the . After a Corner break feature is applied, all model Joints' Type (Rip or Bend) and Style (Edge joint or Butt joint) are no longer editable in the Sheet metal table and flat view.It is recommended to add any Corner break features after finalizing all edits to the Sheet metal model's flanges and joints. Corner joint welding is a specialized process used to join two pieces of material that are connected at a 90-degree angle, creating an L-shape. Experienced. . With thinner pieces, like sheet metal, flush corners will do the job adequately. With intervening thicknesses, a half-open corner weld may be best. . Discover the 7 most common sheet metal joint techniques that include riveted, welded, and adhesive joint types for appropriate enhancement of structural rigidity and effectiveness in your projects. . When sewing plates with corners and other surfaces, for instance, it is virtually almost impossible to achieve a near-perfect fit so that the .

Sheet metal joints are found in every sheet metal assembly. Sheet metal fabrication techniques create these special joints to enable the proper function of t.Flush Corner Joints. A flush corner joint is designed primarily for welding sheet metal 12 gauge and Lighter. It is restricted to light materials because deep penetration is sometimes difficult to achieve, and the joint is able to support . Corner Joint Weld. Corner joints refer to the intersection of two pieces joined at a 90-degree angle, resembling the shape of an ‘L’. This joint occurs where two pieces of metal are perpendicular to each other in an L .

Editing an existing sheet metal model’s bends, rips, and joints using the Sheet metal table creates a Modify joint feature in the Feature list. Edit this feature as you would any other; right-click the feature entry to access the context menu. . Select a corner edge or vertex and specify corner break type and distance. It is recommended to . Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Tab - Add a tab to a sheet metal flange.; Make joint - Convert the intersection of two walls into a joint feature, either a bend (walls joined by cylindrical geometry) or a rip (small gap between two walls).; Corner - Modify a corner type and relief scale.; Bend relief - Modify a .

sheet metal seams pdf

sheet metal overlap joint

For reference, attached is a solution that gives nice corner overlap with minimal gap and equal set back on both sides. It is based on my original design and unfolds correctly. It is not as nice in some respects as a design based solely on sheet metal tools but IMO gives a better result. But, in respect to my original question.

Corner Joint: being one of the most popular welds in the sheet metal industry the corner joint is used on the outer edge of the piece. This weld is a type of joint that comes together at right angles between two metal parts to form an L. These are common in the construction of boxes, box frames and similar fabrications. Chapter #6 – Sheet Metal Seams. Seams run longitudinal along the length of the duct run, while joints run transverse (across). Seams run parallel to the air flow, while joints are perpendicular to the air flow. The seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces together.Flush Corner Joint. Best used for welding 12-gauge or thinner sheet metal, the flush corner joint design can support only moderate loads. Good weld penetration is often difficult with this type of joint (Figure 5 View A). Half-Open Corner Joint. Because penetration is better, use the half-open corner (Figure 5 View B) joint for welding members . These joints are common in sheet metal fabrication, pipelines, and structural applications. . A corner joint is used when two pieces of metal are joined together at a 90-degree angle, forming a corner. You’ll often find these joints in frames, boxes, and other structures that require right angles. It’s important to maintain a steady hand .

Adhesives also provide a joint with better appearance and eliminate distortion caused by high welding temperatures. Corner joints – sheet metal Corner joints can be assembled with adhesives by using simple supplementary attachments. This permits joining and sealing in a single operation. Typical designs are right angle butt joints, slip Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Tab - Add a tab to a sheet metal flange.; Make joint - Convert the intersection of two walls into a joint feature, either a bend (walls joined by cylindrical geometry) or a rip (small gap between two walls).; Corner - Modify a corner type and relief scale.; Bend relief - Modify a .

Similar to tee welding joints, they are corner joints. However, the placement of the metal makes a difference. In contrast to corner joints, which can meet in the 'corner' in either an open or closed way to form an 'L' shape, tee joints place their joint in the middle. These joints are among the most used in the sheet metal industry.

8/3 junction box

Maryland Metal Fabrication provides quality steel products to the entire state. We do welding, plasma cutting, bending, and much more. Give us a call today!

sheet metal corner joints|interlocking sheet metal joints