sheet metal costing template Each part has unique characteristics and therefore SOLIDWORKS provides three default costing templates. Machining (Machined/Casted/Plastic Parts: .sldctm) Multibody (Weldments/Assemblies: .sldctc) SheetMetal . Our Flower Window Boxes TM brand Nottingham style metal window box is .

0 · solidworks costing template

1 · solidworks cost sheet template

2 · sheet metal parts cost estimator

3 · sheet metal manufacturing costs

4 · sheet metal fabrication cost estimator

5 · sheet metal fabrication cost

6 · how to create costing template

7 · how to calculate sheet material

How to wire an electrical junction box. A junction box is used to add a spur or to extend circuits and direct power to lights and additional sockets. Advice on wiring electrical junction box with easy to follow junction box wiring diagrams, including information on 20 and 30 amp junction boxes.

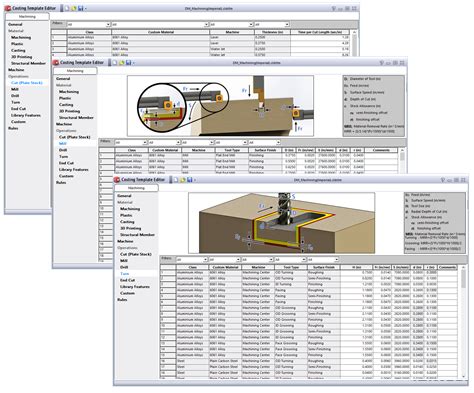

In the Costing Task Pane, under Costing Templates, click Launch Template Editor. In the Costing Template Editor, next to Sheet metal template, click View. You can specify the file location for .You can create and edit costing templates for sheet metal parts or bodies from the Costing Template Editor. You can specify rates and costs for the procedures required to manufacture a .

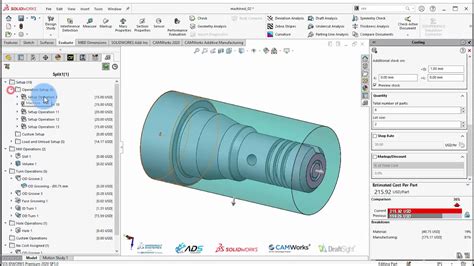

Each part has unique characteristics and therefore SOLIDWORKS provides three default costing templates. Machining (Machined/Casted/Plastic Parts: .sldctm) Multibody (Weldments/Assemblies: .sldctc) SheetMetal . SOLIDWORKS Costing (available in SOLIDWORKS Professional & Premium) is a powerful tool that can estimate production costs for manufactured components using parameters such as raw material costs, . Need to Save time in creating Costing templates. A simple and strait forward hands on process to use SOLIDWORKS Costing. Topics are: General overview Editing.

In this example, we will review editing a sheet metal template. After selecting a sheet metal template that you created, use the drop-down menu in the SOLIDWORKS Costing Template Editor to define material parameters, such .Costing Template Editor for Sheet Metal Parts. You can create and edit costing templates for sheet metal parts or bodies from the Costing Template Editor. You can specify rates and costs .

You can create and edit costing templates for sheet metal parts or bodies from theCosting Template Editor. You can specify rates and costs for the

-Select General tab and select Currency and which templates that shall be used for Sheet Metal and Machining. -Select Custom tab and add cost for operations as Painting etc. -Select Weld Bead tab and add cost for welding .Sheet Metal Operation Costs. The best way to find sheet metal operation costs is to consult your in-house manufacturing department. Recommendation: If you work in a manufacturing department, consult your machine tool supplier for cut rate estimates.This information is often contained in the software provided with the machine tool or in related documentation.Editing Sheet Metal Operations. You can edit manufacturing operations in the Costing template or in the CostingManager. Estimating Sheet Metal Part Costs with the Sheet Size Option. Including Percent Scrap in Sheet Metal Costing. To include scrap material in the cost of a sheet metal part, you can designate a percentage of the part as scrap .

Creating a New Sheet Metal Template. You can create new sheet metal templates for use with the Costing tool. Editing a Sheet Metal Template. You can modify Costing templates any time there are changes in cost structures. For example, if the price of steel increases, you can change the cost in the template. Costing Template Editor for Sheet .

Sheet Metal Costing: Machining Costing: Multibody Parts Costing: Assembly Costing Rollup: Weldments Costing: Costing Task Pane: CostingManager: . Unique Rules for Sheet Metal Templates * Comment: * I acknowledge I have read and I hereby accept the privacy policy under which my Personal Data will be used by Dassault Systèmes:Creating a Limited-access Costing Template. You can create a limited-access Costing template to share with other users. . You can customize machining and sheet metal templates to more accurately reflect the manufacturing process for creating parts. The templates include customizable rules for handling special geometry cases such as large .With SOLIDWORKS Costing, you can eliminate the stress and variability of the task by automating the process of Cost Estimation on Sheet Metal Parts, Milled and Turned Parts, Plastic and 3D Printed parts, and Weldments.You can create and edit costing templates for sheet metal parts or bodies from the Costing Template Editor. You can specify rates and costs for the procedures required to manufacture a sheet metal part or body in the sheet metal template. You can include customized information in the template, such as material cost and thicknesses, cost of .

Editing Sheet Metal Operations. You can edit manufacturing operations in the Costing template or in the CostingManager. Estimating Sheet Metal Part Costs with the Sheet Size Option. Including Percent Scrap in Sheet Metal Costing. To include scrap material in the cost of a sheet metal part, you can designate a percentage of the part as scrap .

Creating a New Sheet Metal Template. You can create new sheet metal templates for use with the Costing tool. Editing a Sheet Metal Template. You can modify Costing templates any time there are changes in cost structures. For example, if the price of steel increases, you can change the cost in the template. Costing Template Editor for Sheet .Creating a New Sheet Metal Template. You can create new sheet metal templates for use with the Costing tool. Editing a Sheet Metal Template. You can modify Costing templates any time there are changes in cost structures. For example, if the price of steel increases, you can change the cost in the template. Costing Template Editor for Sheet .Sheet metal fabricators also have these same choices. The most significant choice involves coatings such as plating or powder coating. In many cases, the cost of the equipment is simply too much given the small amount of customer requirements for the coating. In other cases, the EPA requirements or the

You can create and edit costing templates for sheet metal parts or bodies from the Costing Template Editor. You can specify rates and costs for the procedures required to manufacture a sheet metal part or body in the sheet metal template. You can include customized information in the template, such as material cost and thicknesses, cost of .

Creating a New Sheet Metal Template. You can create new sheet metal templates for use with the Costing tool. Editing a Sheet Metal Template. You can modify Costing templates any time there are changes in cost structures. For example, if the price of steel increases, you can change the cost in the template. Costing Template Editor for Sheet .

Sheet Metal Operation Costs. The best way to find sheet metal operation costs is to consult your in-house manufacturing department. Recommendation: If you work in a manufacturing department, consult your machine tool supplier for cut rate estimates.This information is often contained in the software provided with the machine tool or in related documentation.Creating a New Sheet Metal Template. You can create new sheet metal templates for use with the Costing tool. Editing a Sheet Metal Template. You can modify Costing templates any time there are changes in cost structures. For example, if the price of steel increases, you can change the cost in the template. Costing Template Editor for Sheet .Sheet Metal template: Sets an existing sheet metal template. Machining template: Sets an existing machining template. Launch Template Editor: Opens the Costing Template Editor for creating or editing Costing templates.

Sheet Metal Operation Costs. The best way to find sheet metal operation costs is to consult your in-house manufacturing department. Recommendation: If you work in a manufacturing department, consult your machine tool supplier for cut rate estimates.This information is often contained in the software provided with the machine tool or in related documentation.Creating a New Sheet Metal Template. You can create new sheet metal templates for use with the Costing tool. Editing a Sheet Metal Template. You can modify Costing templates any time there are changes in cost structures. For example, if the price of steel increases, you can change the cost in the template. Costing Template Editor for Sheet .Creating a New Sheet Metal Template. You can create new sheet metal templates for use with the Costing tool. Editing a Sheet Metal Template. You can modify Costing templates any time there are changes in cost structures. For example, if the price of steel increases, you can change the cost in the template. Costing Template Editor for Sheet .

In a sheet metal or machining part, click Costing (Tools toolbar or Tools > SOLIDWORKS Applications > Costing). In the Costing Task Pane, under Costing Template, click Launch Template Editor. In the Costing Template Editor, under Operations: For sheet metal parts, click Cut or Bend. For machined parts, click Cut, Mill, Drill, or Turn. Editing an existing template is simple and straight forward. In this example, we will review editing a sheet metal template. After selecting a sheet metal template that you created, use the drop-down menu in the SOLIDWORKS Costing Template Editor to define material parameters, such as material class and SOLIDWORKS Material.Sheet Metal template: Sets an existing sheet metal template. Machining template: Sets an existing machining template. Launch Template Editor: Opens the Costing Template Editor for creating or editing Costing templates.

solidworks costing template

To display the Sheet Metal Costing Template Editor, click Sheet Metal Costing (Tools toolbar). In the Sheet Metal Costing Task Pane, under Costing Template, click Launch Template Editor.. You can specify the file location for Costing templates in Tools > Options > System Options > File Locations.In Show folders for, select Costing templates to add or delete a location.

Sheet Metal Operation Costs. The best way to find sheet metal operation costs is to consult your in-house manufacturing department. Recommendation: If you work in a manufacturing department, consult your machine tool supplier for cut rate estimates.This information is often contained in the software provided with the machine tool or in related documentation.Setup. The Setup folder contains the costs associated with manufacturing setups such as setting up machines to run a batch (lot) of parts. Each operation to manufacture the part requires a setup cost. If the setup cost is in the sheet metal template, it is recognized by the Costing tool.You can create and edit costing templates for sheet metal parts or bodies from the Costing Template Editor. You can specify rates and costs for the procedures required to manufacture a sheet metal part or body in the sheet metal template. You can include customized information in the template, such as material cost and thicknesses, cost of .

Hosted on 9/10/20 by Jordan KleinschmidtIn this session we will show how SOLIDWORKS Costing can be used as an evaluative method to cost or estimate designs i.

can you use set screw pinions on a cnc machine

can you put electric fence charger in metal box

SSDB-12 - Stainless Steel Double Boiler with Cover - 12 Quart SSDB-12 - Stainless Steel Double Boiler with Cover - 12 Quart SKU: SSDB-12. Email; Print; PDF; Size: 12 qt. 12 qt; 16 qt; 20 qt; 8 qt; Induction ready; Cover included; Stainless steel; Tri-ply bottom; Features. NSF Listed; Cash & .

sheet metal costing template|sheet metal manufacturing costs