cnc machine cad part via computer to machine Modern CNC machining systems can interpret the part geometry directly from the 3D CAD file with the onboard computer or receive the G-code output of the CAM software. Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

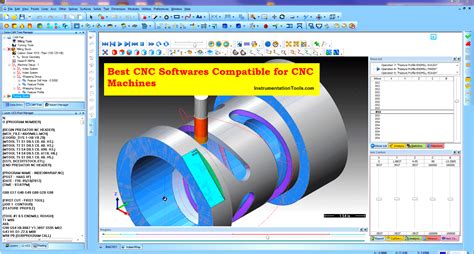

0 · software used in cnc machines

1 · programming software for cnc machines

2 · free cad software for cnc

3 · cnc milling machine programming software

4 · cnc machine software download

5 · cnc machine file types

6 · cad drawing for cnc machine

7 · best cabinet software for cnc

WEST END SHEET METAL WORKS, INC. is a Massachusetts Domestic Profit Corporation filed on May 23, 1956. The company's filing status is listed as Involuntary .

But how exactly does a part go from a computer-aided design (CAD) file to a finished product ready for use? Let’s embark on a journey through the fascinating process of CNC machining, . Modern CNC machining systems can interpret the part geometry directly from the 3D CAD file with the onboard computer or receive the G-code output of the CAM software.

But how exactly does a part go from a computer-aided design (CAD) file to a finished product ready for use? Let’s embark on a journey through the fascinating process of CNC machining, exploring each step from initial design to final inspection.

cnc fiber laser cutting machine factory

Therefore, this article is dedicated to helping you learn how to prepare CAD files for CNC machining. 1. Optimize Tolerances. 2. Type of Material. 3. Minimize the Number of Machined Features. 4. Minimize Machined Stock Allowance. 5. Standardize Features. 6. Surface Finish. 7. Provide Adequate Strength and Stiffness. 8. The CNC Workflow is divided into three main phases: Design Phase: Designing and creating a CAD (Computer Aided Design) model of the desired part. Program Phase: CAM (Computer Aided Manufacturing), creating Toolpaths/G-Codes for the machining of the desired part. CNC Phase: Using a CNC machine to cut the designed part from a workpiece. Current CNC machining systems can read the part’s geometry directly from the 3D CAD file with the on-board computer or from the G-code output of the CAM (Computer-aided manufacturing) software. In this regard, a 2D drawing is not .Once the CAD model is complete, it needs to be converted into a CNC-compatible format using CAM (Computer-Aided Manufacturing) software. This step involves generating the G-code, which is the language CNC machines understand. Software Used: CAM software like Mastercam or .

Connect disciplines using common CAD models to program CNC machines. Design fixtures and create toolpaths before engineering data is released—any changes automatically update computer-aided manufacturing (CAM) workflows.

software used in cnc machines

The Working Mechanism of CNC Software. The main function of computer numerical CNC software is to determine the movement of devices that operate machined parts and materials based on the digitized model prepared earlier. It all begins with CAD (computer-aided design) when the user constructs the 3D form for designing on the computer. CAD models designed for fabrication using computer numerical control (CNC) machining must follow specific principles and best practices. Well-designed CAD models make the CNC programming and machining process quicker, more efficient, and higher quality.

Using computer-aided design (CAD) software is the first step to creating a physical part made by a CNC machine. The CAD software creates highly detailed 3D models. However, they don’t instruct the CNC machine how to operate to make the part you want. Here are some essential steps to take when you’re getting your CAD model ready for a CNC machine. Modern CNC machining systems can interpret the part geometry directly from the 3D CAD file with the onboard computer or receive the G-code output of the CAM software.

But how exactly does a part go from a computer-aided design (CAD) file to a finished product ready for use? Let’s embark on a journey through the fascinating process of CNC machining, exploring each step from initial design to final inspection.

Therefore, this article is dedicated to helping you learn how to prepare CAD files for CNC machining. 1. Optimize Tolerances. 2. Type of Material. 3. Minimize the Number of Machined Features. 4. Minimize Machined Stock Allowance. 5. Standardize Features. 6. Surface Finish. 7. Provide Adequate Strength and Stiffness. 8. The CNC Workflow is divided into three main phases: Design Phase: Designing and creating a CAD (Computer Aided Design) model of the desired part. Program Phase: CAM (Computer Aided Manufacturing), creating Toolpaths/G-Codes for the machining of the desired part. CNC Phase: Using a CNC machine to cut the designed part from a workpiece.

Current CNC machining systems can read the part’s geometry directly from the 3D CAD file with the on-board computer or from the G-code output of the CAM (Computer-aided manufacturing) software. In this regard, a 2D drawing is not .

Once the CAD model is complete, it needs to be converted into a CNC-compatible format using CAM (Computer-Aided Manufacturing) software. This step involves generating the G-code, which is the language CNC machines understand. Software Used: CAM software like Mastercam or .Connect disciplines using common CAD models to program CNC machines. Design fixtures and create toolpaths before engineering data is released—any changes automatically update computer-aided manufacturing (CAM) workflows. The Working Mechanism of CNC Software. The main function of computer numerical CNC software is to determine the movement of devices that operate machined parts and materials based on the digitized model prepared earlier. It all begins with CAD (computer-aided design) when the user constructs the 3D form for designing on the computer.

CAD models designed for fabrication using computer numerical control (CNC) machining must follow specific principles and best practices. Well-designed CAD models make the CNC programming and machining process quicker, more efficient, and higher quality.

cnc engine parts

programming software for cnc machines

free cad software for cnc

cnc enhanced screw machining

cnc milling machine programming software

Flux core welding, also known as flux-cored arc welding (FCAW), is a welding method that utilizes a continuously fed electrode with a flux core. The flux core acts as a shielding agent, protecting the weld pool from contaminants and atmospheric gases.

cnc machine cad part via computer to machine|cnc machine file types