cnc machine capabilities Learn about how the many different kinds of CNC machines work, the materials available, the benefits & limitations, basic design rules and the most common applications. Electrician Explains Electrical Codes for Home Electrical Junction Boxes with Photos, Wiring Diagrams and Answers to Your Questions

0 · how many axis are there

1 · how does cnc machine work

2 · high end cnc machines

3 · cnc mill axis diagram

4 · cnc machining guide

5 · cnc machine how it works

6 · cnc machine advantages and disadvantages

7 · 5 axis vs 6 cnc

2024T3 Alclad Aluminum Sheet Aluminum alloy sheet is sold in the thicknesses and sheet sizes shown in the table. Minimum sheet size available is 2' X 4'. Order by part number.

how many axis are there

Learn about how the many different kinds of CNC machines work, the materials available, the benefits & limitations, basic design rules and the most common applications.In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis . Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages .

CNC (Computer Numerical Control) machines are automated tools controlled by a computer executing pre-programmed sequences of machine control commands. These machines combine mechanical design with .

Explore cutting-edge CNC machine capabilities and their wide range of applications. Achieve exceptional quality and efficiency with precise engineering.

CNC machining is a subtractive manufacturing process that creates parts by selectively removing portions of a workpiece using cutting tools or media. To understand CNC machining, it's essential to first grasp what CNC (Computer .Learn about CNC machining processes in the comprehensive guide by Dassault Systèmes, enabling precise and efficient production of complex parts.CNC stands for Computer Numerical Control and refers to the automated control of machining tools, such as drills, lathes, mills, grinders, routers, and 3D printers, using a computer. The CNC machining process involves inputting coded .

Learn about how the many different kinds of CNC machines work, the materials available, the benefits & limitations, basic design rules and the most common applications.

In short, CNC machining is a metal fabrication method where written code controls the machinery in the manufacturing process. The code determines everything from the movement of the cutting head and the part to spindle speed, RPMs, etc. CNC machining services use a subtractive fabrication method. There are 15 different types of CNC machines, each with their own unique capabilities. The most common types include milling machines, lathes, routers, and grinders. These are the 15 types of CNC I’ll cover in this article: 1. CNC Routers. CNC routers have a large bed for laying sheet material.

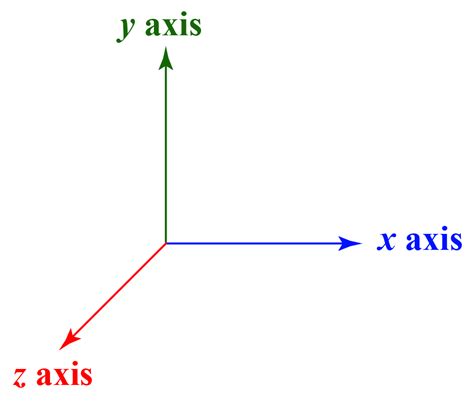

In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes. Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the . CNC (Computer Numerical Control) machines are automated tools controlled by a computer executing pre-programmed sequences of machine control commands. These machines combine mechanical design with software-based control, allowing for high precision and repeatability in manufacturing processes. Explore cutting-edge CNC machine capabilities and their wide range of applications. Achieve exceptional quality and efficiency with precise engineering.

CNC machining is a subtractive manufacturing process that creates parts by selectively removing portions of a workpiece using cutting tools or media. To understand CNC machining, it's essential to first grasp what CNC (Computer Numerical Control) is.Learn about CNC machining processes in the comprehensive guide by Dassault Systèmes, enabling precise and efficient production of complex parts.

how does cnc machine work

CNC stands for Computer Numerical Control and refers to the automated control of machining tools, such as drills, lathes, mills, grinders, routers, and 3D printers, using a computer. The CNC machining process involves inputting coded instructions into a computer, which translates the code into precise movements for the cutting tools.Learn about how the many different kinds of CNC machines work, the materials available, the benefits & limitations, basic design rules and the most common applications.In short, CNC machining is a metal fabrication method where written code controls the machinery in the manufacturing process. The code determines everything from the movement of the cutting head and the part to spindle speed, RPMs, etc. CNC machining services use a subtractive fabrication method. There are 15 different types of CNC machines, each with their own unique capabilities. The most common types include milling machines, lathes, routers, and grinders. These are the 15 types of CNC I’ll cover in this article: 1. CNC Routers. CNC routers have a large bed for laying sheet material.

In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.

Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the . CNC (Computer Numerical Control) machines are automated tools controlled by a computer executing pre-programmed sequences of machine control commands. These machines combine mechanical design with software-based control, allowing for high precision and repeatability in manufacturing processes. Explore cutting-edge CNC machine capabilities and their wide range of applications. Achieve exceptional quality and efficiency with precise engineering.CNC machining is a subtractive manufacturing process that creates parts by selectively removing portions of a workpiece using cutting tools or media. To understand CNC machining, it's essential to first grasp what CNC (Computer Numerical Control) is.

Learn about CNC machining processes in the comprehensive guide by Dassault Systèmes, enabling precise and efficient production of complex parts.

An enswell is a small metal tool used to apply pressure to an injury to reduce swelling. It is often kept on ice and used by a fighter’s second, cornerman, or cutman to apply direct pressure to bruising or swelling especially around the .

cnc machine capabilities|cnc machine how it works