aerospace cnc machine In this comprehensive guide, we’ll take a deep dive into the world of aerospace CNC machining, exploring the materials, benefits, cutting tools and strategies, surface . Four-inch round pan boxes (short for “pancake”) come in handy if a ceiling joist is right where you need to install your dining room light fixture. Cutting a notch in the ceiling joist would weaken it.

0 · machining aerospace parts

1 · cnc machining aerospace parts

2 · cnc aerospace parts

3 · aircraft cnc machining

4 · aerospace manufacturing cnc machining

5 · aerospace machinist

6 · aerospace cnc machining services

7 · aerospace cnc machine shop

The additional axis on a 6-axis CNC machine can create complex shapes and improve machining capabilities. Other configurations may have the main advantage of 6-axis machines, but the speed and ability to significantly .

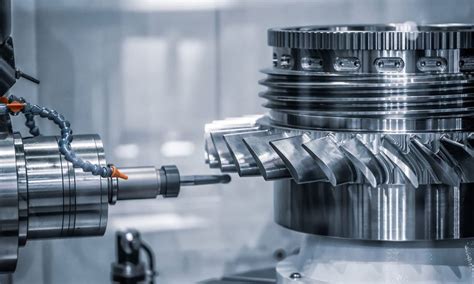

What Is CNC Machining for Aerospace? CNC machining for aerospace is a specialized manufacturing process that uses computer numerical control (CNC) machines to produce high-precision parts for aircraft and .The world of aerospace CNC machining revolves around Computer Numerical Control (CNC), a technology that turns digital blueprints into physical parts with incredible accuracy. This process relies heavily on computer-aided design . What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, .CNC Machining aerospace parts creates lightweight, durable materials and supports rapid prototyping, low-volume, and high-volume production, meeting strict safety standards while .

In this comprehensive guide, we’ll take a deep dive into the world of aerospace CNC machining, exploring the materials, benefits, cutting tools and strategies, surface . The aerospace CNC machining process involves using computer-controlled machine tools to shape raw materials, such as metals or composites, into finished aerospace components. The process starts with a digital 3D .

Aerospace CNC machining involves the use of computer-controlled machines to fabricate precise components for aircraft and spacecraft. This advanced manufacturing process allows for the . Aerospace CNC machining involves using computer-aided tools and components to produce and maintain aircraft and space parts. It is a computerized manufacturing method that moves cutting tools using pre .

machining aerospace parts

Explore how CNC machining produces precise, lightweight aerospace components, from complex parts to rapid prototyping, ensuring safety and innovation. Aerospace components are developed and designed using .The aerospace sector thrives on continuous improvement, especially in relation to lightweighting and safety. The combination of Computer-Aided Design (CAD) software and CNC machining enables aerospace engineers to design, refine . What Is CNC Machining for Aerospace? CNC machining for aerospace is a specialized manufacturing process that uses computer numerical control (CNC) machines to produce high-precision parts for aircraft and spacecraft.

The world of aerospace CNC machining revolves around Computer Numerical Control (CNC), a technology that turns digital blueprints into physical parts with incredible accuracy. This process relies heavily on computer-aided design (CAD) and computer-aided manufacturing (CAM) tools.

What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, components, and assemblies which are essential for crafts used in the aerospace industry.CNC Machining aerospace parts creates lightweight, durable materials and supports rapid prototyping, low-volume, and high-volume production, meeting strict safety standards while reducing lead times and minimizing human error. In this comprehensive guide, we’ll take a deep dive into the world of aerospace CNC machining, exploring the materials, benefits, cutting tools and strategies, surface treatments, and applications that make this technology so essential to the industry. The aerospace CNC machining process involves using computer-controlled machine tools to shape raw materials, such as metals or composites, into finished aerospace components. The process starts with a digital 3D model .

Aerospace CNC machining involves the use of computer-controlled machines to fabricate precise components for aircraft and spacecraft. This advanced manufacturing process allows for the production of complex parts with tight tolerances, ensuring optimal performance and safety in aerospace applications. Aerospace CNC machining involves using computer-aided tools and components to produce and maintain aircraft and space parts. It is a computerized manufacturing method that moves cutting tools using pre-programmed code and software. Explore how CNC machining produces precise, lightweight aerospace components, from complex parts to rapid prototyping, ensuring safety and innovation. Aerospace components are developed and designed using the best technology, ensuring they meet the highest standard.

The aerospace sector thrives on continuous improvement, especially in relation to lightweighting and safety. The combination of Computer-Aided Design (CAD) software and CNC machining enables aerospace engineers to design, refine and create parts with ease. What Is CNC Machining for Aerospace? CNC machining for aerospace is a specialized manufacturing process that uses computer numerical control (CNC) machines to produce high-precision parts for aircraft and spacecraft.The world of aerospace CNC machining revolves around Computer Numerical Control (CNC), a technology that turns digital blueprints into physical parts with incredible accuracy. This process relies heavily on computer-aided design (CAD) and computer-aided manufacturing (CAM) tools.

What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, components, and assemblies which are essential for crafts used in the aerospace industry.

CNC Machining aerospace parts creates lightweight, durable materials and supports rapid prototyping, low-volume, and high-volume production, meeting strict safety standards while reducing lead times and minimizing human error.

In this comprehensive guide, we’ll take a deep dive into the world of aerospace CNC machining, exploring the materials, benefits, cutting tools and strategies, surface treatments, and applications that make this technology so essential to the industry. The aerospace CNC machining process involves using computer-controlled machine tools to shape raw materials, such as metals or composites, into finished aerospace components. The process starts with a digital 3D model .Aerospace CNC machining involves the use of computer-controlled machines to fabricate precise components for aircraft and spacecraft. This advanced manufacturing process allows for the production of complex parts with tight tolerances, ensuring optimal performance and safety in aerospace applications.

Aerospace CNC machining involves using computer-aided tools and components to produce and maintain aircraft and space parts. It is a computerized manufacturing method that moves cutting tools using pre-programmed code and software. Explore how CNC machining produces precise, lightweight aerospace components, from complex parts to rapid prototyping, ensuring safety and innovation. Aerospace components are developed and designed using the best technology, ensuring they meet the highest standard.

cnc machining aerospace parts

nec hidden junction box

cnc aerospace parts

What Exactly Is a Box Junction? Definition of a Box Junction. A box junction is a road traffic control measure designed to prevent congestion and ensure the smooth flow of vehicles through busy intersections. It is characterised by a grid of criss-cross yellow lines painted on the road surface.

aerospace cnc machine|cnc aerospace parts