stretch forming operation in sheet metal Sheet metal stretching is a process used to shape metal components by subjecting the metal sheet to forces that cause it to elongate and change shape. What factors affect the sheet metal stretching process? Specializing in high-quality custom metal stampings, deep draw stamping, sheet metal fabrication processing, precision metal casting and forming parts & components, progressive die stamping, tool and die capabilities and value-added assembly.

0 · what is stretch forming process

1 · what does stretch forming mean

2 · stretch forming techniques

3 · stretch forming presses

4 · stretch draw forming press

5 · sheet metal forming tools

6 · sheet metal forming

7 · advantages of stretch forming process

Shop for steel sheet at America's Metal Superstore. Largest selection of Hot Rolled Steel Sheet, Cold Rolled Steel Sheet, Galvanized Steel Sheet at wholesale prices. Any Quantity, Any Size, Delivered Anywhere!

Stretch forming is a metal forming process that simultaneously stretches and bends a selected material over a machined form, called a die, to form a part with one or several different curve radii. This process produces perfectly curved .

Stretch forming is a metal fabrication technique that stretches and bends metal over a die to create curved shapes. It uses tension to pull the material taut while forming it around a mold, resulting in uniform thickness and minimal spring-back.Stretch Forming is a forming process that involves metal wherein a piece of metal is stretched and bent. This process is usually done on a stretch press wherein .

Sheet metal stretching is a process used to shape metal components by subjecting the metal sheet to forces that cause it to elongate and change shape. What factors affect the sheet metal stretching process?

Stretch forming of a sheet metal is a forming process that involves stretching a metal sheet over a die to produce complex and contoured shapes. It is commonly used in the .Calculate the force required to stretch form a wing span from a sheet of 2219 aluminum having a cross-sectional area of 13x305 mm, a yield strength of 250 MPa and a UTS of 360 Mpa.This article discusses the applicability, advantages, and machines and accessories of stretch forming. It provides a detailed discussion on four methods of stretch forming, namely, stretch draw forming, stretch wrapping, . This classification involves bending, blanking, stretch forming and deep drawing. Each process has some parameters that define the quality of the work achieved. This paper .

Sheet metal is a thin piece of metal between 0.006 and 0.25 inches thick. Sheet metal can be cut, bent, and stretched into various shapes through forming and cutting operations. Common forming operations include . Sheet Metal Forming Techniques. There are several sheet metal forming techniques used in the manufacturing industry, each with its advantages and limitations. These methods can be broadly classified into three categories: .

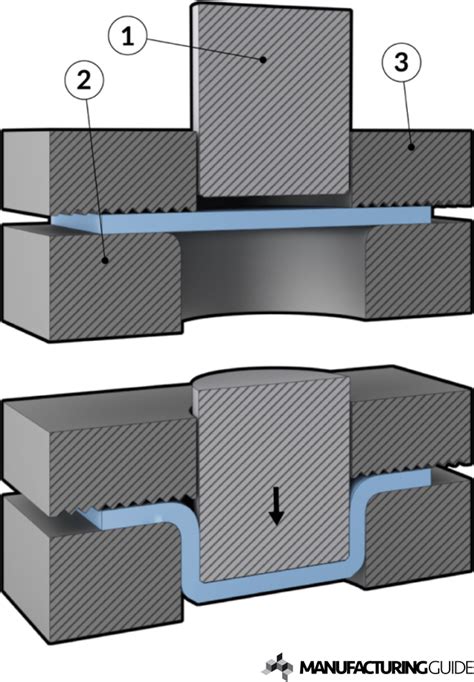

Stretching/stretch forming Stretch forming is a sheet metal forming process in which the sheet metal is intentionally stretched and simultaneously bent to have the shape change. Sheet is held by jaws or drawbeads at both the ends and then stretched by punch, such that the sheet is stressed above yield strength.

what is stretch forming process

what does stretch forming mean

best hydraulic chuck cnc turning center manufacturer

Study with Quizlet and memorize flashcards containing terms like The surface area of the workpiece is likely to: a. undergo little change during a sheet operation, b. it is likely to change significantly in bulk forming. c. a & b. d. none of the above., Shearing is the mechanical cutting of materials: a. without the formation of chips b. without the use of burning or melting. c. a & b. d. . Sheet Metal Stretch Forming Sheet Presses are used to form large size sheet stock into contoured shapes. They are typically used in . The stretch forming process is seldom suited to progressive or transfer operations. Although the process can create sharp contours and reentrant angles, it is best for forming shallow or nearly flat shapes. . 11. • Bending (Forming the metal between a suitably shaped punch and forming block. ) • Drawing (consist of a punch forcing a sheet metal blank to flow plastically into the clearance available between the punch and die surfaces so as to acquire top shape, a cylindrical shape or a box shape ) • Sequeezing (metal is caused to flow to all portions of a die cavity .

Sheet metal forming operations include bending, stretching, deep drawing, and other processes where sheets are formed. Bending involves shaping a straight length into a curve and can be done using presses or rolls. . Stretch forming clamps sheet edges and stretches the sheet over a die into the desired shape. 3. Successful forming requires . Press for Sheet Metal Press selection for sheet metal forming operations depends on several factors: Type of forming operation, and dies and tooling required Size and shape of work pieces Length of stroke of the slide, stroke per minute, speed and shut height (distance from the top of the bed to the bottom of the slide, with the stroke down .Q1 A 20 inch long sheetmetal workpiece is stretched in a stretch forming operation to the dimensions shown in Figure (a). The thickness of the beginning stock t= 0.125 inch and the width 10 inches. The metal has a flow curve defined by K = 70,000 lb/in2 and n 0.25.

Drawing 4. Other Sheet Metal Forming Operations 5. Dies and Presses for Sheet Metal Processes 6. Sheet Metal Operations Not Performed on Presses . Sheet metal is stretched and simultaneously bent to achieve shape change Stretch forming: (1) start of process; (2) form die is pressed into the work with force Fdie, causing it to be stretched and .The first part of the course deals with several concepts in metal forming and plasticity, and the second part includes theoretical analyses of few sheet forming and tube forming operations. The course will be useful to design engineers, stamping engineers, manufacturing students and scholars, and academia.

Stretch forming has several advantages compared to pure bending and other types of metal forming. Stretch wrap forming machines stretch the metal to its elastic limit, then wrap the part around a forming die, increasing the metal’s yield strength and resulting in a stronger part. . Sheet stretch forming machines are designed to meet all .

An example is to reduce sidewall curl by replacing sheet metal flowing through draw beads and over a die radius with a simple 90 degree bending operation. . These post-stretch forming operations normally require significantly higher forming forces and energy requirements to be effective for several reasons. A. true B. false A.true explanation:-in stretch forming, a metal sheet is stretched by the help of stretcher machines. for proper and complete stretching of sheet, the material is deformed plastically which is also called as permanent deformation. the metal sheet is stressed above its yield strength for successfully achieving the plastic deformation of the metal sheet.Stretching is the sheet metal forming process where the punch which creates the part shape forces the sheet metal to thin since lock beads prevent metal flow inward from the flange area. In contrast with drawing, significant metal thinning .

The amount of tension must be controlled to avoid cracking of the sheet metal. Stretch forming is a process often used in the aircraft building industry. . Drawing is a sheet-metal-forming operation used to make cup- .SHEET STRETCH FORMING Sheet Stretch Forming is a fast, economical, and accurate way to form a large panel from a metal sheet. The process involves stretching the sheet to a calculated yield point and forming it over a tool. Transverse Sheet Stretch Forming Press (FET/T) Up to 12 independently controlled axes allow forIn the sheet metal hydroforming process, a metal blank is placed on the hydroform press. This blank is the metal sheet onto which pressure is applied, which forces the blank into the shape of the die beneath it. The advantage of this method is the versatility; a wide variety of parts can be formed using sheet hydroforming. “As part producers seek to expand their capabilities, many have approached us with new stretch forming applications. Combining modern CNC technology with our precise digital die mapping technology and historically robust machine structure provides for the finely tuned automated motion control necessary to maintain constant strain in the part throughout the .

Subject - Manufacturing Processes, MetallurgyChapter - Difference between Bending, Drawing, Slitting, Trimming, Shaving Process in Metal forming OperationsT.

Bending 3. Stretch forming 4. Drawing. There are various sheet metal forming processes which may be broadly classified as 1. Shearing 2. Bending 3. Stretch forming 4. Drawing. . Shaving is cutting operation that involves the quality and accuracy of blanked parts by removing a thin strip of metal along the edges. Only about 100 microns (0.004 .A 0.5 m long sheet metal workpiece is stretched in a stretch forming operation to the dimensions shown in Figure below. The thickness of the beginning stock is 12.5 mm and the width is 216 mm. The metal has a flow curve defined by a strength coefficient of 520 MPa and a strain hardening exponent of 0.20. The yield strength of the material is .

“Multi-point stretch forming (MPSF)” concept is derived from MPF (Zhou et al., 2005), a MPSF tooling has been developed and used to stretch form aircraft outer skin parts as shown in Fig. 1.The purpose of this paper is to investigate and understand the basic physical phenomena in the multi-point stretch forming of sheet metal, including the influence of the .and substitution of sheet metal. INTRODUCTION A complex forming operation can be resolved into three major deformation components: drawing, stretch- ing and bending. Forming operations consisting of pure drawing, stretching or bending are uncommon. Most often, the deformation in a complex stamping results

12. Sheet metal parts are usually made by forming material in a cold condition , although many sheet metal parts are in a hot condition because the material when heated has a lower resistance to the deformation. Spring or blanks are very often used as initial materials, and are formed on press using appropriate tools. The shape of the part generally corresponds to .

A shearing process where a tool is forced through the sheet metal workpiece forming a hole. punching. shearing. bending. notching. 9 of 31. Term. Punching a number of holes in a sheet . stretch forming. 20 of 31. Term. Subject the part to tension while being bent. stretch forming . A shearing operation typically carried out with a pair of .A finite-element process modeling program, SHEET-3, was developed using triagnular elements for simulating the sheet-metal stretch forming operation of an arbitrarily-shaped punch and dies. The program employs an implicit, incremental algorithm based on a rigid-viscoplastic constitutive equation with corrections for material unloading. Contact and friction are introduced through a .

best metal for fabrication

stretch forming techniques

CNC Routing - SendCutSend: Custom Sheet Metal Fabrication

stretch forming operation in sheet metal|what does stretch forming mean