use of cnc machine CNC Milling Machines: First, CNC milling machines use rotary cutting tools to remove material from a workpiece and make it into a shape or form that the user wants. These CNC machines help cut, shape, and drill different kinds of materials. They are often used to make precise and complicated parts. Key Components: P4W have been in business more than 10 years providing high-quality precision turned parts, from simple assemblies to complex, from relax to tight-tolerance turned components. Our experts manufacture any turning parts & screw machine parts needed to run your business.

0 · what can cnc machines make

1 · types of cnc lathe machines

2 · process of cnc machine

3 · how cnc machine is controlled

4 · function of cnc machine

5 · different kinds of cnc machines

6 · computer numerical control cnc machines

7 · companies that use cnc machines

As one of the leading power distribution box manufacturers and suppliers in China, we warmly welcome you to wholesale bulk power distribution box from our factory. All products are with high quality and competitive price.

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. A CNC machine, or computer numerical control machine, is a piece of equipment that manufactures parts according to preprogrammed computer directions. The techniques you can apply in CNC machines are even more .

CNC machining has revolutionised manufacturing with its numerous CNC machine advantages when compared to conventional machining. By replacing manual processes with computer numerical control, it offers .

cnc brake parts

The capacity to rotate materials while in use defines lathe CNC machines. They are shorter and more compact than CNC milling machines because they have fewer axes. A lathe that controls and transmits material to .CNC Milling Machines: First, CNC milling machines use rotary cutting tools to remove material from a workpiece and make it into a shape or form that the user wants. These CNC machines help cut, shape, and drill different kinds of materials. They are often used to make precise and complicated parts. Key Components: An APC, or automatic parts chute, is a device that is used on some CNC machines to automatically eject parts that have been machined. The APC is connected to the CNC machine and is typically located underneath the machine. When the CNC machine is finished machining a part, the APC will automatically eject the part into a chute or onto a . How to use a Dial Indicator: Dial indicators are useful for setting up jobs and adjusting your CNC machine. How to use Edge Finders: Edge Finders are also use for setting up jobs on your CNC machine. How to use a Micrometer: Micrometers are one of the first super-precision measuring tools you’ll learn to use.

CNC machines often use programs created by CAM software. CAM allows users to set up a “job tree” to organize workflow, set tool paths and run cutting simulations before the machine does any real cutting. Often CAM programs work as add-ons to CAD software and generate g-code that tells the CNC tools and workpiece moving parts where to go.

what can cnc machines make

4-axis CNC machines enhance the capabilities of 3-axis machines by introducing an additional axis of rotation. With this added axis, these machines can perform tasks like indexing, milling helical shapes, and cutting irregular profiles. 4-axis CNC machines are commonly found in applications involving complex cylindrical or curved parts.CNC machines are now capable of producing intricate and precise components across various industries with minimal human intervention. Today, CNC technology is an integral part of modern manufacturing, contributing to efficiency, accuracy, and automation. It has shaped the way products are designed, developed, and produced, revolutionizing .

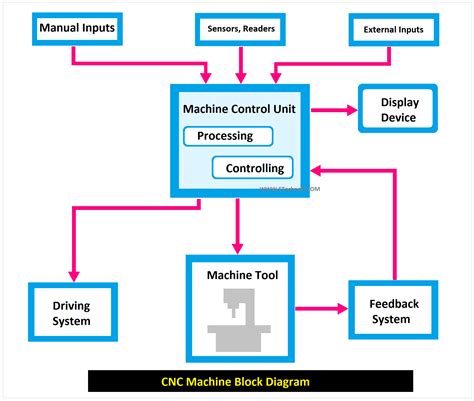

CNC machines automate many tasks but still require skilled operators and programmers. Rather than replacing workers, they are transforming the nature of manufacturing jobs. Can I use a CNC machine for small-scale or hobby projects? Yes, there are many desktop CNC machines designed for hobbyists and small businesses. 3. Introduction to CNC 3 Numerical control (NC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium, as opposed to controlled manually. Most NC today is computer numerical control (CNC), in which computers play an integral part of the control. In modern CNC systems, end-to-end component .

Small businesses can benefit greatly from the use of CNC machines to optimize their manufacturing processes. These machines offer precision, reliability, and flexibility, enabling small businesses to produce high-quality products efficiently. CNC machines are instrumental in streamlining production and improving overall productivity.

10 Industries that Use CNC Machines: 1. Aerospace Industry: In the aerospace industry, CNC machines are crucial for making parts you depend on when flying. 5-axis CNC mills and CNC lathes are commonly used to craft precise parts from tough materials like titanium and aluminum. These machines produce engine parts that help planes fly and landing . A CNC machine works by following a computer-aided design (CAD) file, which is a digital model of the part or object that needs to be created. This CAD file is then converted into a set of numerical data, called G-code, that tells the CNC machine how to move. The machine can cut, shape, drill, or engrave materials like metal, plastic, wood, or .

CNC machines are computer-controlled devices that use a series of cutting tools to create objects from metal, plastic, or other materials. The object is designed on a computer, and the CNC machine then follows the instructions .

How to use CNC machine? At present, there is a diversity of individuals who classify as CNC machine tool operators, including those who are familiar with machining but not with programming, newly graduated students .A CNC machine that operates on wood CNC machines typically use some kind of coolant, typically a water-miscible oil, to keep the tool and parts from getting hot. A CNC metal lathe with the door open.. In machining, numerical control, also . In today's fast-paced world of PCB manufacturing, precision and efficiency are key. That's where CNC machines come in.These computer-controlled machines have revolutionized the way electronic components are produced. In this article, we will delve deeper into the world of CNC machines, exploring their definition, functionality, and the array of benefits they offer.So, .

CNC machining is the go-to method for making jewellery and etching and engraving. Jewelry-making uses CNC milling machines, CNC lathes, CNC routers, and CNC laser engraving machines. A jewellery CNC machine not only helps manufacture and form metal jewelry but also in grinding and polishing items. In the manufacturing industry, the use of CNC machines has become dominant. It promises improved processing and quality results. It also holds the key for a fast, accurate and cost-efficient operation – it helps minimize expense as it cuts costs on paying workers that serve the same function as the machines. In terms of benefits, [.]

cnc brass lathe turning part joint factories

The right selection of cutting tools to be used in processing is an important step in planning production on CNC machines. They must also meet the strict product quality requirements and provide . CNC Electrical Discharge Machines (EDM) use electric sparks to remove material from conductive workpieces to reshape materials. The sparks vaporize minute bits of material, removing thin layers of metal. CNC electrical discharge machines work only for conductive materials and have a slow cutting rate. They can be used for manufacturing .The CNC machine does not use blades to cut the material, but instead it uses a variety of tools such as saws, drill bits, router bits and knives. The process of using the CNC machine is fairly straightforward. The user needs to import the design file into the CNC software program and then set up the tool paths for cutting or carving out the . In CNC machine shops, meticulous programs are designed or prepared beforehand and then fed into the CNC machine. The CNC machine, in turn, adheres to the instructions outlined in the program, expertly controlling the motion and speed of the machine tools to achieve exceptional levels of precision and productivity. Fig 1: CNC machine

CNC machines have revolutionized the manufacturing industry with their precision and efficiency. In this beginner's guide, we will explore the world of CNC machines and how to operate them effectively.Whether new to CNC machining or looking to enhance your skills, this guide will provide valuable insights and step-by-step instructions. On the other hand, CNC laser cutting machines use laser beams to cut through a wide range of materials with exceptional precision. The laser beam creates a localized heating effect, causing the material to vaporize or melt, resulting in high-quality cuts. CNC laser cutting machines are commonly used in industries such as aerospace, electronics .

types of cnc lathe machines

process of cnc machine

Laser-cutting CNC machines commonly use one of these three types of lasers that is CO2, neodymium (Nd), or yttrium-aluminum-garnet (Nd: YAG). 6. CNC Plasma Cutting Machine. This machine similar to milling CNC machines, plasma-cutting CNC machines are also used to cut materials. But, they differ from their milling counterparts by doing this .

cnc brass parts milling processing quotes

how cnc machine is controlled

China Cnc Non-standard Turning Parts wholesale - Select 2024 high quality Cnc Non-standard Turning Parts products in best price from certified Chinese CNC Cutting Machine manufacturers, Cnc Machining Part suppliers, wholesalers and factory on Made-in-China.com

use of cnc machine|what can cnc machines make