minimum sheet metal thickness In the fabrication industry, ‘gauge’ is an identifier for the standard thickness of sheet metal of a specific material. The gauge size is based on the weight of the metal sheet and is inversely proportional to the thickness, which means the higher it is, the thinner the . See more Get the best deals for Stainless Steel Table Used at eBay.com. We have a great online selection at the lowest prices with Fast & Free shipping on many items!

0 · which thickness called sheet metal

1 · steel sheet gauge size chart

2 · sheet steel thickness chart

3 · sheet steel gauges thickness chart

4 · sheet metal thickness chart printable

5 · sheet metal thickness chart pdf

6 · sheet metal gauge range chart

7 · sheet metal chart pdf

Machining Centers - Vertical Machining Centers for sale listings - We have 2488 listings for Vertical Machining Centers listed below. Find items by using the following search options. You can also click on the column heading to sort through the listings.

Standard sheet metal thickness and size varies across different metals. Find standard sheet metal gauges and mm measurements in this article. See moreIn Australia, the typical thickness of sheet metal is between 0.5 millimetres and 6 millimetres. Anything thicker 6 millimetres is classified as metal plate, and anything thinner than 0.5 . See more

In the fabrication industry, ‘gauge’ is an identifier for the standard thickness of sheet metal of a specific material. The gauge size is based on the weight of the metal sheet and is inversely proportional to the thickness, which means the higher it is, the thinner the . See moreThere are two ways to measure sheet metal: using a measuring tape (which is less precise) and a gauge wheel (more typically used in the industry). See moreYes, sheet metal thickness is important as it determines what kind of fabrication processes can be used. Thinner sheet metal is suitable for different processes and different . See more

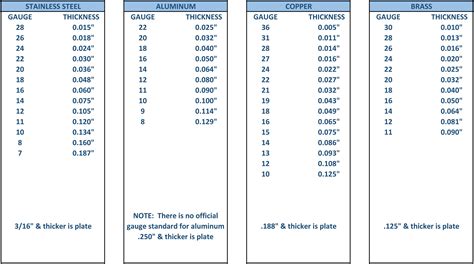

The chart below can be used to determine the equivalent sheet thickness, in inches .Sheet metal is available in flat pieces or coiled strips. The coils are formed by running a continuous sheet of metal through a roll slitter. In most of the world, sheet metal thickness is consistently specified in millimeters. In the U.S., the . The bend’s outer edge would crack if it exceeds the minimum bend radius which is typically specified according to the metal sheet thickness (t) like 1t, 2t, 3t etc. . Thickness of the sheet: Minimum bend radius: 1–6 mm: 1 time the . Material Thickness. Because sheet metal parts are manufactured from a single sheet of metal, the part must maintain uniform wall thickness. Sheet metal thickness ranges from 0.024 in. (0.609mm) to 0.250 in. (6.35mm).

Table of Contents. 1 Common Bend Radius Design Mistakes; 2 Sheet Metal Part Design for Manufacturing Tip. 2.0.1 UNABLE TO UNFOLD PART, SHEET METAL BEND RADIUS ISSUE RESOLVED; 3 How to implement the industry standard sheet metal bend radius. 3.1; 3.2 Your Partner in Precision Sheet Metal Design; 4 Sheet Metal Part Design for Manufacturing . Experience in actual sheet metal processing shows that when the plate thickness is generally no more than 6mm, the inner radius of sheet metal bending can directly use the plate thickness as the radius. When the bending radius is r = 0.5, the general sheet metal thickness t is equal to 0.5mm.

DUCT CONSTRUCTION MINIMUM SHEET METAL THICKNESS FOR SINGLE DWELLING UNITS a. ROUND DUCT DIAMETER (inches) STATIC PRESSURE: 1 / 2-inch water gauge: 1-inch water gauge: Thickness (inches) Thickness (inches) . Round metallic ducts shall be mechanically fastened by means of not less than three sheet metal screws or rivets spaced . Selecting the appropriate sheet thickness is a pivotal step in sheet metal fabrication. This choice influences a variety of factors including the part's overall strength, weight, and integral design features such as minimum bend radii, hole and slot sizes, and flange length.Minimum Bend Radii: . Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation, the radius can be near zero for thin sheet metal. . Below is a conversion chart that converts sheet metal gauge numbers into metal thickness. 26 gauge: 24 ga. 22 ga. 20 ga . 18 ga. 16 ga. .

What is the minimum thickness one can order A36 Steel sheet? I am doing a calc and the designer specified 1/8" A36 sheet, but the customer is now saying that A36 does not come in a thickness less than 3/16".What is the minimum bend radius of a sheet metal? Don't know? Terms in this set (51) . Metal removed or length of repair, thickness and alloy of the material, rivet diameter. What should not be used when doing a layout on sheet metal aluminum? A scribe. What is used as an aid when doing layout work with pencil?

The minimum recommended sheet metal flange bend length avoid cracks in the bending area. It shall be equal to three times of sheet thickness plus bend radius. Minimum Sheet Metal Flange Bend Length = 3 x Sheet Thickness + Bend Radius. Sheet metal Hole Diameter Guidelines.When working with sheet metal, the term “gauge” is often used. Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system. Originally used in the fields of medicine and jewellery, the larger the As a general recommendation, ±0.005 in. runs right at the limit of precision flat sheet metal in a job shop environment. For bent sheet metal, variation in the raw material thickness increases the recommended precision to ±0.010 in. per bend. Layout Method for Sheet Metal “Sheet metal stretches when it bends” is an oversimplification.

which thickness called sheet metal

4 Precision Sheet Metal Size FAQ. 4.0.1 What factors should I consider when choosing the right sheet metal gauge for my project? 4.0.2 How can I ensure I'm using the right material thickness for my sheet metal project? 4.0.3 Can you share a real-life example of how choosing the right sheet metal gauge made a significant difference in a project? Parts must maintain a uniform wall thickness throughout their entirety. Generally, Xometry is capable of manufacturing sheet metal parts up to 3/8" (9.525mm) in thickness, but this tolerance mainly depends on the .

did roman boxing gloves have metal inserts

DUCT CONSTRUCTION MINIMUM SHEET METAL THICKNESS FOR SINGLE DWELLING UNITS a. ROUND DUCT DIAMETER (inches) STATIC PRESSURE: 1 / 2-inch water gage: 1 inch water gage: Thickness (inches) Thickness (inches) . (25 mm) and shall be mechanically fastened by means of not less than three sheet-metal screws or rivets equally spaced around the joint.Form height to thickness ratio – To determine the minimum form height for sheet metal use the following formula: D = 2.5T + R (see below) The height can be less but it required secondary . Corners - May be sharp, however to reduce tooling costs, specify radii of ½ material thickness or a minimum of .015”. Notches and Tabs- should not be .

For thin sheet metal welding it can be 30 ampere while for thicker (e.g. 1/8” square groove weld)- it can go up to 220 ampere for example. GMAW-S gives low heat and makes it easy to use in all positions on sheet metal, low carbon steel, low alloy steel, and stainless steel sheet metal from 25 gauge (0.02 inch or 0.5 mm) to 12 gauge (0.1 inches or 2.6 mm). Round ducts and enclosed rectangular ducts 14 inches or less minimum thickness 0.0157 equivalent galvanized gauge size 28. M1601.1.1 Above-ground duct systems. Above-ground duct systems shall conform to the following: 4. Minimum thickness of metal duct material shall be as listed in Table M1601.1.1(2). Galvanized steel shall conform to ASTM A 653. The requisite thickness is a function of the applied loads. If your sheet suffers only tension, then the calculation is trivial: the total applied tensile force divided by the sheet's cross-sectional area has to be less than the allowable (not characteristic) stress in the steel.This assumes the force is evenly applied along the sheet.Sheet copper or aluminum shall be at least 0.51 mm (0.020 in.) thick. Sheet steel shall be at least 0.41 mm (0.016 in.) thick. Related Code Sections (C) Special Equipment, Minimum Thickness of Enclosure Metal. . Minimum Thickness of Enclosure Metal. 250.94 Wiring and Protection, Bonding for Communications Systems .

Q: In a previous Bending Basics article, you mention a “material’s tensile reduction percentage” used for calculating the minimum inside bend radius of various metals. You described a rough rule to find a steel’s minimum bend radius: Divide 50 by the material’s reduction percentage, as specified by the material supplier, subtract by 1, and then multiply by the plate . When welding sheet metals, the thickness (or the gauge) of the sheet metal is not a big problem when concerning thicker sheets. However, welding is much less flexible when working upon thinner materials. Our recommendations for the minimum and maximum sheet metal thickness would start at no less than 16 gauge or 1.5mm and max out at 6mm (15/64 Thicker sheet metal provides an added layer of protection, especially in the event of a collision. Regulatory bodies set standards for minimum thickness, ensuring that vehicles meet certain safety criteria. Advances in Automotive Sheet Metal Technology. Advancements in technology have led to innovations in sheet metal manufacturing. The bend’s outer edge would crack if it exceeds the minimum bend radius which is typically specified according to the metal sheet thickness (t) like 1t, 2t, 3t etc. . Thickness of the sheet: Minimum bend radius: 1–6 mm: 1 time the thickness of the sheet: 6–12 mm: 1.5 times the thickness of the sheet:

Wall Thickness. Because Sheet Metal parts are manufactured from a single sheet of metal the part must maintain a uniform wall thickness. Sheet metal parts with a minimum of 0.9mm to 20mm in thickness can be manufactured. Hole Diameter. When designing parts for laser cutting one should not make holes smaller than the thickness of the material. Bends See how and when specifically to design bend reliefs and corner reliefs in sheet metal parts to open up geometry options & tighter tolerances . We provide a simple calculation you can do to determine a safe minimum size for your bend relief. Width: The width of your relief should be at least half the thickness of your material. Relief Width .

steel sheet gauge size chart

sheet steel thickness chart

Our used fabrication equipment makes your job of cutting, bending, and assembling easier and faster. We carry a wide inventory of metal fabricating machines, and most have their own category on our website.

minimum sheet metal thickness|sheet metal chart pdf