cutting force calculator for sheet metal Sheet Metal; Bend Allowance; Bending Springback; V-Bending Force; Wipe Bending Force; Deep Drawing Force; Bend Allowance Calculator. Sheet thickness (in): . Deep Drawing Force Calculator. Sheet thickness (in): Blank . Continuous seam welding is a process used to join two metal sheets together seamlessly. It involves creating an electric arc between the two pieces of metal, melting them, and then quickly cooling them down to form one solid piece.

0 · sheet metal shear strength calculator

1 · sheet metal shear cutting strength

2 · sheet metal forming calculator

3 · sheet metal drawing strength calculator

4 · sheet metal calculator

5 · sheet metal bending force calculator

6 · shearing force calculator sheet metal

7 · shear cutting force calculator

Dakotaland Manufacturing (formerly Westland MFG & JMS Precision) Precision Sheet Metal Fabrication, CNC Machining, Welding. ISO Quality Certification.

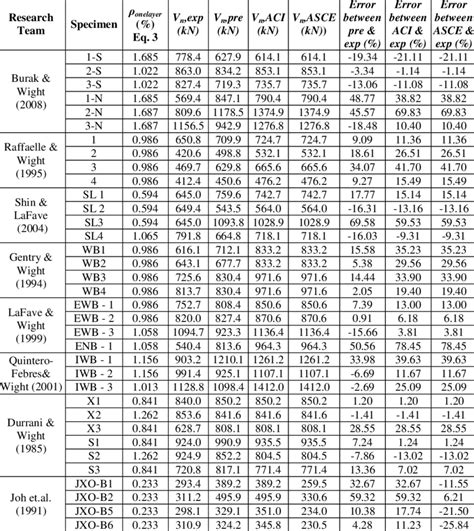

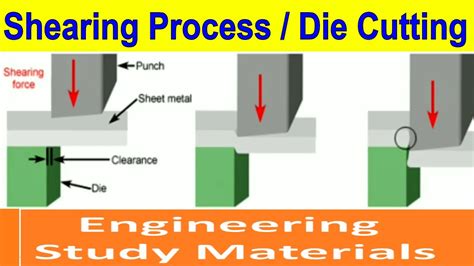

Force required to shear sheetmetal equation and calculator. A shear force is applied that will cut off part of a sheet. The cut off ‘blank’ becomes the workpiece. To find the shear force for a cut we can go back to the basic mechanics of .How to calculate the cutting force of a guillotine shear. With this calculator you can determine the force required to shear sheet metal, simply by entering the material’s ultimate tensile strength, thickness, and blade angle (rake angle).Calculate the shearing force required to cut sheet metal based on material strength, thickness, and cutting length. Input the material properties and cutting specifications to determine the .Sheet Metal; Bend Allowance; Bending Springback; V-Bending Force; Wipe Bending Force; Deep Drawing Force; Bend Allowance Calculator. Sheet thickness (in): . Deep Drawing Force Calculator. Sheet thickness (in): Blank .

Use our sheet metal calculator to easily estimate bending and punching forces for precise metalworking. Ideal for quick, accurate calculations in fabrication. . Laser Cutting Machine .

Learn how to accurately calculate sheet metal cutting force with our comprehensive guide. Improve your machining process and increase efficiency. Visit us now! The shearing force required depends on various factors, including the material properties of the sheet metal (such as its shear strength), the thickness of the sheet, the cutting method, and the geometry of the cut.The document describes how to calculate the cutting force required to shear sheet material. It provides the calculated cutting force of 44.952 tons or 440832 newtons for a sheet 672mm long and 2mm thick made of a material with a .

You can use the cutting force equation to figure out how much blades use when manufacturing materials like foil or metal while learning about the underlying physics involved .

Shear force on metal sheets refers to the cutting force acting on the metal sheet during the shearing process. The shear cutting force depends on several factors: material strength, material thickness, shear tool sharpness, .Force required to shear sheetmetal equation and calculator. A shear force is applied that will cut off part of a sheet. The cut off ‘blank’ becomes the workpiece. To find the shear force for a cut we can go back to the basic mechanics of materials (with one adjustment factor). Preview: Force required to shear sheetmetal calculatorHow to calculate the cutting force of a guillotine shear. With this calculator you can determine the force required to shear sheet metal, simply by entering the material’s ultimate tensile strength, thickness, and blade angle (rake angle).Calculate the shearing force required to cut sheet metal based on material strength, thickness, and cutting length. Input the material properties and cutting specifications to determine the shearing force.

Sheet Metal; Bend Allowance; Bending Springback; V-Bending Force; Wipe Bending Force; Deep Drawing Force; Bend Allowance Calculator. Sheet thickness (in): . Deep Drawing Force Calculator. Sheet thickness (in): Blank diameter (in): Punch diameter (in): Ultimate tensile strength (psi): Factor of safety: Drawing ratio:Use our sheet metal calculator to easily estimate bending and punching forces for precise metalworking. Ideal for quick, accurate calculations in fabrication. . Laser Cutting Machine Rolling Machine V Grooving Machine panel bender Support. expertise tutorials download service calculator Showcase. video . Learn how to accurately calculate sheet metal cutting force with our comprehensive guide. Improve your machining process and increase efficiency. Visit us now! The shearing force required depends on various factors, including the material properties of the sheet metal (such as its shear strength), the thickness of the sheet, the cutting method, and the geometry of the cut.

The document describes how to calculate the cutting force required to shear sheet material. It provides the calculated cutting force of 44.952 tons or 440832 newtons for a sheet 672mm long and 2mm thick made of a material with a shear strength of 328N/mm^2.

sheet metal shear strength calculator

sheet metal shear cutting strength

You can use the cutting force equation to figure out how much blades use when manufacturing materials like foil or metal while learning about the underlying physics involved in cutting. This can give you an idea of the force required to cut a wire or other material.

Shear force on metal sheets refers to the cutting force acting on the metal sheet during the shearing process. The shear cutting force depends on several factors: material strength, material thickness, shear tool sharpness, shearing speed, and tool gap.

Force required to shear sheetmetal equation and calculator. A shear force is applied that will cut off part of a sheet. The cut off ‘blank’ becomes the workpiece. To find the shear force for a cut we can go back to the basic mechanics of materials (with one adjustment factor). Preview: Force required to shear sheetmetal calculator

How to calculate the cutting force of a guillotine shear. With this calculator you can determine the force required to shear sheet metal, simply by entering the material’s ultimate tensile strength, thickness, and blade angle (rake angle).

Calculate the shearing force required to cut sheet metal based on material strength, thickness, and cutting length. Input the material properties and cutting specifications to determine the shearing force.Sheet Metal; Bend Allowance; Bending Springback; V-Bending Force; Wipe Bending Force; Deep Drawing Force; Bend Allowance Calculator. Sheet thickness (in): . Deep Drawing Force Calculator. Sheet thickness (in): Blank diameter (in): Punch diameter (in): Ultimate tensile strength (psi): Factor of safety: Drawing ratio:Use our sheet metal calculator to easily estimate bending and punching forces for precise metalworking. Ideal for quick, accurate calculations in fabrication. . Laser Cutting Machine Rolling Machine V Grooving Machine panel bender Support. expertise tutorials download service calculator Showcase. video . Learn how to accurately calculate sheet metal cutting force with our comprehensive guide. Improve your machining process and increase efficiency. Visit us now!

The shearing force required depends on various factors, including the material properties of the sheet metal (such as its shear strength), the thickness of the sheet, the cutting method, and the geometry of the cut.The document describes how to calculate the cutting force required to shear sheet material. It provides the calculated cutting force of 44.952 tons or 440832 newtons for a sheet 672mm long and 2mm thick made of a material with a shear strength of 328N/mm^2.

You can use the cutting force equation to figure out how much blades use when manufacturing materials like foil or metal while learning about the underlying physics involved in cutting. This can give you an idea of the force required to cut a wire or other material.

sheet metal forming calculator

sheet metal drawing strength calculator

Stick welding of SMAW welding for Thin Sheet Metal Welding. Material as thin as 16 gauge, approximately 1/16 in. (2 mm) thick up to several feet thick, can be Stick welded. Stick welding is one of the options to perform sheet metal welding, especially in field welding applications. Related reading: Best Stick Welding Rod for Thin Sheet Metal .

cutting force calculator for sheet metal|sheet metal shear cutting strength