cnc machine clamp Improve your CNC machining performance with the right clamps. Discover the best selection process and types of clamps for various CNC . There are various types of steel trusses used in the construction industry. They are described further below in this article: We are going to learn each and every type of steel trusses in a detailed manner; A Pratt Truss has been used .

0 · mill table holding clamps

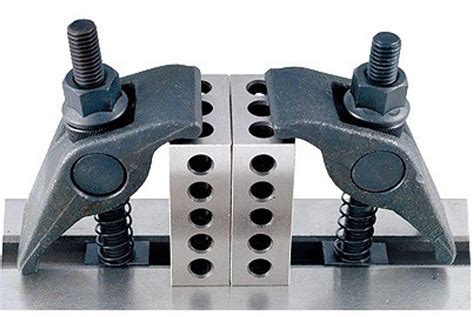

1 · machine work holding clamps

2 · cnc toe clamp hold down

3 · cnc hold down clamps

4 · clamps for milling machine table

5 · clamps for cnc router table

6 · clamps for cnc machine table

7 · clamping systems for cnc mills

Identify different types of welds with 100% accuracy. 4 Square Butt Joints Used to butt weld light sheet metal. 1/16 to 3/16 thick metal. 5 Beveled Butt Joints Used to butt weld heavier pieces of metal together. 3/8 to ½ inch metal can welded using a single V or U joint. ½ Inch metal and up can be welded using a double V or U joint.

Improve your CNC machining performance with the right clamps. Discover the best selection process and types of clamps for various CNC .

Increase the operation time of your CNC machining centers and manual machines. Flexible, Zero-Point Clamping System 9000 offers solutions to reduce setup times. Whether your workpieces .Choose from our selection of milling machine clamps, including over 850 products in a wide range of styles and sizes. In stock and ready to ship.There are many types of clamps for CNC machine tools. However, their selection for CNC machining must meet production requirements. If the wrong chuck is selected, the workpiece and tool can be damaged by vibration, broken tool tip, . From hydraulic/pneumatic clamps for heavy-duty applications to versatile block/combination clamps for varying workpiece configurations, the array of CNC machine workpiece clamping caters to the intricacies of modern machining.

Improve your CNC machining performance with the right clamps. Discover the best selection process and types of clamps for various CNC machine tools in this comprehensive guide.A comparison of 8 different types of clamping systems for CNC milling based on safety, cost, ergonomics, adaptability and compatibility with different working areas.

Increase the operation time of your CNC machining centers and manual machines. Flexible, Zero-Point Clamping System 9000 offers solutions to reduce setup times. Whether your workpieces are clamped directly on pallets or in palletized vises or fixtures, precise and quick retooling of your machines allows absolute flexibility in your production .Choose from our selection of milling machine clamps, including over 850 products in a wide range of styles and sizes. In stock and ready to ship.

There are many types of clamps for CNC machine tools. However, their selection for CNC machining must meet production requirements. If the wrong chuck is selected, the workpiece and tool can be damaged by vibration, broken tool tip, loose material, etc.

Capable of clamping one or two workpieces with one clamp. Offered in flat, hole, and serrated edge types. allow parts to be clamped by an inner diameter. The machinable clamp allows for custom sizes and shapes of ID features to be secured.The trusted global leader in workholding fixture solutions for CNC machining centers and milling machines. As the original inventor of the wedge-operated Low-profile Clamp, OK-VISE® has been at the forefront of fixturing innovations for years. Selecting a CNC fixture or clamp should consider the types of CNC machining center, precision requirements, batch size, processing cost and more factors.

Here are a few guidelines to choose an appropriate type of CNC clamping system for low volume and high volume CNC production. Generally, the combination clamps are suitable for small-scale production. A building block clamp or . From hydraulic/pneumatic clamps for heavy-duty applications to versatile block/combination clamps for varying workpiece configurations, the array of CNC machine workpiece clamping caters to the intricacies of modern machining. Improve your CNC machining performance with the right clamps. Discover the best selection process and types of clamps for various CNC machine tools in this comprehensive guide.A comparison of 8 different types of clamping systems for CNC milling based on safety, cost, ergonomics, adaptability and compatibility with different working areas.

Increase the operation time of your CNC machining centers and manual machines. Flexible, Zero-Point Clamping System 9000 offers solutions to reduce setup times. Whether your workpieces are clamped directly on pallets or in palletized vises or fixtures, precise and quick retooling of your machines allows absolute flexibility in your production .Choose from our selection of milling machine clamps, including over 850 products in a wide range of styles and sizes. In stock and ready to ship.There are many types of clamps for CNC machine tools. However, their selection for CNC machining must meet production requirements. If the wrong chuck is selected, the workpiece and tool can be damaged by vibration, broken tool tip, loose material, etc.Capable of clamping one or two workpieces with one clamp. Offered in flat, hole, and serrated edge types. allow parts to be clamped by an inner diameter. The machinable clamp allows for custom sizes and shapes of ID features to be secured.

The trusted global leader in workholding fixture solutions for CNC machining centers and milling machines. As the original inventor of the wedge-operated Low-profile Clamp, OK-VISE® has been at the forefront of fixturing innovations for years. Selecting a CNC fixture or clamp should consider the types of CNC machining center, precision requirements, batch size, processing cost and more factors.

mill table holding clamps

cheap cnc machining aluminum

Mill, Lathe, Router, Drills, EDM, Waterjet, Laser, Grinder, and Turn-mill are the most common types of CNC machines. Learn which one is best.

cnc machine clamp|cnc hold down clamps