cnc grinding machine diagram Centerless Grinding Machine Process Operation For Round Pieces (Parts And Functions) Surface grinding on CNC GRINDER .more. CNC Plasma Cutters use a high-velocity stream of ionized gas to cut parts out of .

0 · micromatic cylindrical grinding machine

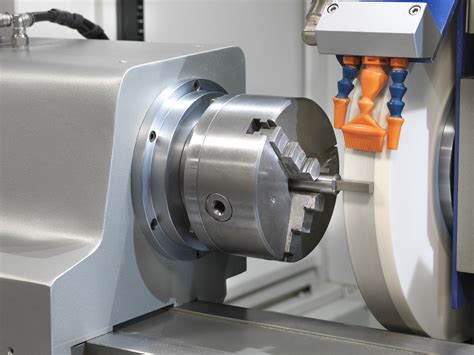

1 · external cylindrical grinding machine

2 · cylindrical grinding machine manufacturers

3 · cnc internal grinding machine

4 · cnc grinding machine specifications

5 · cnc grinding machine manufacturers

6 · cnc end mill grinding machine

7 · cnc cylindrical grinding machine price

Certified ISO 9001:2015 - Specializing in custom manufacturing of metal enclosures, metal carts, metal displays, and industrial cabinetry. We work with sheet metal, tubing, rigid wire, aluminum and more.

micromatic cylindrical grinding machine

cnc machine workshop in dubai

external cylindrical grinding machine

Okuma’s new control uses the latest CPUs for a tremendous boost in operability, rendering performance, and processing speed. The OSP suite also features a full range of useful apps .Download the Okuma Grinding Machine Guide to learn what a grinding machine .9/Series CNC Grinder Operation and Programming Manual - Rockwell Automation . 1

CNC grinding machines offer straightforward programming and efficient operation, making them ideal for precision manufacturing. Utilizing G-code and M-code, along with CAM software, simplifies the programming . Centerless Grinding Machine Process Operation For Round Pieces (Parts And Functions) Surface grinding on CNC GRINDER .more.Please select the Model/Type of machine from the list below:-

In this guide, we will look at the various types of CNC machines, including lathe machines, routers, milling machines, grinders, and many more. We’ll uncover how they work, how manufacturers use them, and what to look .A computer numerical control (CNC) system, showcasing the block diagram of cnc machine, consists of three basic components: CNC software which is a program of instructions, a machine control unit, and processing equipment, .

cnc machined bearing part

CNC machines come in many different configurations, but the most common are CNC mills and CNC lathes. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or .Okuma’s new control uses the latest CPUs for a tremendous boost in operability, rendering performance, and processing speed. The OSP suite also features a full range of useful apps that could only come from a machine tool manufacturer, making smart manufacturing a reality. A CNC grinding machine, or CNC grinder, operates automatically with minimum intervention from a machinist or operator. It follows programmed instructions to produce smooth surface finishes while reducing distortion and increasing the grinding process’s efficiency.9/Series CNC Grinder Operation and Programming Manual - Rockwell Automation . 1

CNC grinding machines offer straightforward programming and efficient operation, making them ideal for precision manufacturing. Utilizing G-code and M-code, along with CAM software, simplifies the programming process and minimizes errors.Download the Okuma Grinding Machine Guide to learn what a grinding machine is, how it works and why you need one on your shop floor. Centerless Grinding Machine Process Operation For Round Pieces (Parts And Functions) Surface grinding on CNC GRINDER .more.

Please select the Model/Type of machine from the list below:-

In this guide, we will look at the various types of CNC machines, including lathe machines, routers, milling machines, grinders, and many more. We’ll uncover how they work, how manufacturers use them, and what to look for as a buyer, .

A computer numerical control (CNC) system, showcasing the block diagram of cnc machine, consists of three basic components: CNC software which is a program of instructions, a machine control unit, and processing equipment, also called machine tool.

CNC machines come in many different configurations, but the most common are CNC mills and CNC lathes. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or angular parts. This .

Okuma’s new control uses the latest CPUs for a tremendous boost in operability, rendering performance, and processing speed. The OSP suite also features a full range of useful apps that could only come from a machine tool manufacturer, making smart manufacturing a reality. A CNC grinding machine, or CNC grinder, operates automatically with minimum intervention from a machinist or operator. It follows programmed instructions to produce smooth surface finishes while reducing distortion and increasing the grinding process’s efficiency.9/Series CNC Grinder Operation and Programming Manual - Rockwell Automation . 1 CNC grinding machines offer straightforward programming and efficient operation, making them ideal for precision manufacturing. Utilizing G-code and M-code, along with CAM software, simplifies the programming process and minimizes errors.

Download the Okuma Grinding Machine Guide to learn what a grinding machine is, how it works and why you need one on your shop floor.

Centerless Grinding Machine Process Operation For Round Pieces (Parts And Functions) Surface grinding on CNC GRINDER .more.Please select the Model/Type of machine from the list below:- In this guide, we will look at the various types of CNC machines, including lathe machines, routers, milling machines, grinders, and many more. We’ll uncover how they work, how manufacturers use them, and what to look for as a buyer, .

A computer numerical control (CNC) system, showcasing the block diagram of cnc machine, consists of three basic components: CNC software which is a program of instructions, a machine control unit, and processing equipment, also called machine tool.

Dive into our online wholesale cnc machined parts products catalog on globalsources.com! Source over 17411 cnc machined parts for sale from manufacturers with factory direct prices, high quality & fast shipping.

cnc grinding machine diagram|cnc end mill grinding machine