standard metal fabrication tolerances EN 1090-2, Clause 11 defines three types of permitted geometrical deviations (tolerances): . Essential tolerances, which relate to criteria that are necessary for mechanical resistance and . Authentic recycled old roofing metal. Similar to rusty corrugated sheet metal. Affordable option or alternative to other higher priced reclaimed paneling products. Buy any quantity here in Reclaimed Lumber Products online store (discounted shipping based on .

0 · structural steel tolerance chart

1 · steel beam tolerance chart

2 · general tolerance chart for fabrication

3 · fabrication tolerances chart

4 · fabrication tolerance chart pdf

5 · erection tolerance chart pdf

6 · bs 5606 pdf free download

7 · british standard tolerance chart

$230K+

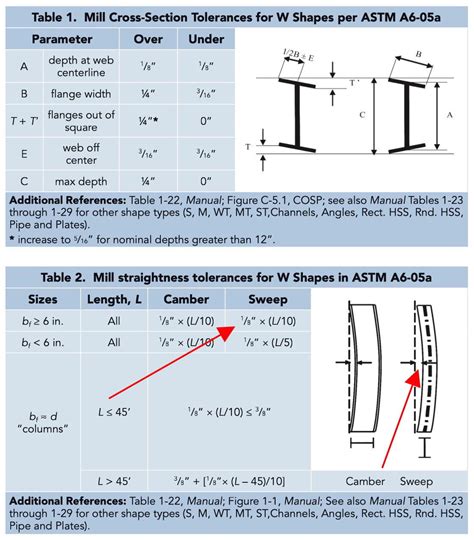

• New Section 11 was added to compile all fabrication and erection tolerances. This addi-tion also included the removal of Section 6.4 and 7.13 from the 2016 Code. • Section 11.2 includes new .An engineer designing with structural steel must account for three types of toler-ance in their design: Mill Tolerance, Fabri-cation Tolerance, and Erection Tolerance. Mills producing hot .In this article, we’ll break down everything you need to know about tolerances in steel structure fabrication, the types of tolerances that exist, and industry standards that guide this critical . We frequently receive RFQs for parts with tolerances that exceed what is achievable in standard fabrication. Most of these issues are related to sheet metal forming, .

EN 1090-2, Clause 11 defines three types of permitted geometrical deviations (tolerances): . Essential tolerances, which relate to criteria that are necessary for mechanical resistance and .ISO Standards: The International Organization for Standardization provides a comprehensive standard set for sheet metal fabrication. ISO 2768, which sets benchmarks without specifying .

Tolerances for the fabrication of structural steel, both hot-rolled and built-up members, can be found in standard codes, such as the AISC Specification for Structural Steel Buildings, both the ASD and LRFD editions; .Fabrication and Erection Tolerances. The AISC Specification for Structural Steel Buildings, the Code of Standard Practice for Steel Buildings and Bridges, AWS D1.1 and other existing .

structural steel tolerance chart

The manufacturing process used for specific features in sheet metal fabrication impacts tolerances. While features located on the same surface can achieve standard tolerances of +/- 0.005", formed features like flanges . Even though the term is used all the time, the reality of manufacturing tolerances can get quite complicated depending on the process in question. This post will compare machining, 3D printing, and sheet metal . Indian Standard TOLERANCES FOR FABRICATION OF STEEL STRUCTURES 0. F 0 R E M’ 0 R D 0.1 . The tolerances for the fabrication of steel railway bridges and allied structures which fall into Group A will be covered in a separate standard. 0.4 This standard keeps in view the practice being followed in this field .

Tolerances in steel fabrication are essential to ensure that a structure is safe, functional, and durable. Whether you’re fabricating components for a skyscraper or a bridge, following industry standards and maintaining strict tolerances is non-negotiable.

Tolerances for the fabrication of structural steel, both hot-rolled and built-up members, can be found in standard codes, such as the AISC Specification for Structural Steel Buildings, both the ASD and LRFD editions; AISC Code of Standard Practice for Steel Buildings and Bridges; AWS D1.1 Structural Welding Code-Steel; AWS D1.5 Bridge Welding .It applies to the dimensions of parts that are produced by metal removal or parts that are formed from sheet metal. NOTES 2 These tolerances may be suitable for use with materials other than metal. 3 Parallel International Standards exist or are planned, e.g. see IS0 60621) for castings. ISO 2768 is an important standard for general tolerances in sheet metal fabrication. It specifies tolerance classes for linear dimensions, angular dimensions (ISO 2768-1) and geometrical tolerances (ISO 2768-2). The standard has four tolerance classes: fine (f), medium (m), coarse (c), and very coarse (v). In sheet metal fabrication, the design of bends and flanges is instrumental in mitigating the spring-back effect and reducing the risk of metal tearing. Utilizing standard die sets, including 0.80 mm (0.030″) tools for internal corners, can be advantageous, or alternatively, consulting with your fabricator about the available tools is essential.

SCI P185 Guidance notes on best practice in steel bridge construction 5.03/1 GN503R3 Revision 3 Scope . testing and thus cover tolerances for both fabrication and erection. At a cost, and given the time, very high levels . good standard of fabrication and substructure set-out, such adjustment points would typically In metal fabrication, there are several tolerance standards commonly used to ensure parts are manufactured correctly and fit together as intended. The most commonly used standards include: ISO 2768 – This international standard is divided into two parts: ISO 2768-1 and ISO 2768-2. ISO 2768-1 applies to linear and angular dimensions without .Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication. Transform your team's workflow with Protocase Designer Enterprise, the game-changing design tool for collaboration! . Standard Tolerances For Copper. Usually, choosing material thickness is one of the first .

processes and common tolerances associated with them as a function of typical part size. The important point to take away fr om this figure is the general trend showing typical achievable part tolerances grow as a function of parts size. In other words, the ability to achieve a certain tolerance is a function of part size. AsTolerances of Machined and Sheet Metal Parts Xometry's Manufacturing Partner Network makes thousands of machines available to make your part at the click of a mouse. Since the minimum requirement to machine a part is a solid CAD file, we offer these general tolerances and guidelines (also found in our Manufacturing Standards ).Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication. Transform your team's workflow with Protocase Designer Enterprise, the game-changing design tool for collaboration! . Standard Tolerances For Perforated Sheet Metal. Usually, choosing material thickness is one .

Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication. Transform your team's workflow with Protocase Designer Enterprise, the game-changing design tool .

Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication. Transform your team's workflow with Protocase Designer Enterprise, the game-changing design tool .

What’s considered a “standard” tolerance differs in precision machining and sheet metal fabrication. A standard tolerance for precision machined parts is +/- 0.005.” A standard tolerance for sheet metal fabricated .In metal fabrication, different tolerances are typically set for different parts of the process. These tolerances are typically small when dealing with very precise projects. . Class 1 is less strict and is the standard for routine fabrication, whereas class 2 is more expensive and requires special measures throughout the process. Indian Standard TOLERANCES FOR FABRICATION OF STEEL STRUCTURES 0. F 0 R E M’ 0 R D 0.1 This Indian Standard was adopted by the Indian Standards Institution on 27 February 1974, after the draft finalized by the Structural Engineering Sectional Committee had been approved by the

This article will explore the key tolerance standards used in subtractive manufacturing, specifically ISO 2768, ISO 286 and GD&T. . Tolerances accommodate larger dimensions and processes like welding or fabrication. Plastic components: . Sheet metal parts: Parts made from sheet metal for enclosures, panels, and brackets where tight fits are .14–1 Accumulated Column Tolerances 289. 14–2 Accumulated Steel Frame Tolerances 290. 14–3 Detailing for Steel Structural System Tolerances 293. 14–4 Detailing for Precast on Steel 295. 14–5 Detailing for Brick on Steel 295. 14–6 Detailing for Stone on Steel Systems 297. 14–7 Detailing for Curtain Walls on Steel Frames 299

steel beam tolerance chart

In sheet metal fabrication, tolerances are your best friend. They’re the factors that determine whether your sub-assemblies fit or if you’ll need to go back to the drawing board. . The standard tolerance range for sheet metal is often within ±0.1 mm, depending on the material thickness and machining process. Linear Tolerances . Next, we .

Standards : IS0 657/V Hot-rolled steel sections - Part V Equal leg angles and unequal leg angles - Tolerances for metric and inch series. IS0 1035/IV Hot-rolled steel bars - Part IV Tolerances of round, square and flat bars - Metric series. IS0 657/13 Tolerances on sloping flange beam, column and ISO Standards: ISO 2768 is a prevalent standard in sheet metal fabrication, covering tolerance requirements for multiple industries. This standard helps in balancing costs and processing capabilities. . Use Standard Tolerance Notations: Adhere to industry standards such as ISO or ANSI for tolerance notations. This ensures that your tolerances . A CAD jockey who understands metal fabrication makes better decisions in applying CAD tools. . For bent part fabrication tolerances, start with ±0.006 in. to allow for accuracy of the fabrication equipment and add 5 percent of the thickness for each bend. . When setting up the Base Flange, specify a thickness that corresponds to standard .

Indian Standard TOLERANCES FOR FABRICATION OF STEEL STRUCTURES 0. F 0 R E M’ 0 R D 0.1 . The tolerances for the fabrication of steel railway bridges and allied structures which fall into Group A will be covered in a separate standard. 0.4 This standard keeps in view the practice being followed in this field . Common Standards for Dimensional tolerances. We adhere to various standards in sheet metal fabrication. ISO 2768 is the most widely used standard for general tolerances, while ANSI Y14.5 is more specific. These standards serve as a guide to ensure consistency in production regardless of the project’s complexity.. It’s not just about compliance; it’s about .

cnc engraving machine with x y z axis

general tolerance chart for fabrication

MI CNC Parts is dedicated to the manufacture of custom made or manufactured CNC Milled, Lathed, Wired EDM, Ground, Lasered, or 3D Printed Parts. We utilize our distributed network for hundreds of suppliers from around North America and the World to deliver you the best possible product at the best possible price.

standard metal fabrication tolerances|british standard tolerance chart