automatic cnc machine data collection Predator MDC is real-time machine monitoring software that automatically collects, reports, charts and processes real-time shop floor manufacturing data including OEE, cycle time, idle time, . Get the best deals for voltron lunch at eBay.com. We have a great online selection at the lowest prices with Fast & Free shipping on many items!

0 · machine data collection system

1 · machine data collection software

2 · machine data collection process

3 · machine data collection platform

4 · machine data collection in manufacturing

5 · cnc machine tracking

6 · cnc machine data collection

7 · cnc data collection software

Designed for WAGO 221 series connectors, cable sizes 1.0MM, 1.5MM & 2.5MM T&E, and 0.75MM & 1MM Flex cable. Can handle up to 32 amps. Meets BS5733 & 18th Edition Wiring Regulations. High-quality polypropylene for durability. Flame retardant to EN60598 standards.

Predator MDC is real-time machine monitoring software that automatically collects, reports, charts and processes real-time shop floor manufacturing data including OEE, cycle time, idle time, . Using Machine Data to Drive Factory Floor Optimization. Automated manufacturing equipment (CNC machines if you will), and the people who operate this equipment, are the .

is illegal to weld sheet metal to a truck

Our fully automated CNC machine monitoring software provides visualizations of real-time manufacturing production data, instant notifications, as well as historical analytics, allowing .A CNC machine monitoring system collects data from each machine control and operator, secures the data via an onsite IoT Gateway, provides access to the data via a mobile-friendly .By automatically detecting nearby employees, machine tools, and jobs, Harmoni automates unproductive data collection and production tasks, all while eliminating potential mistakes and .

What is CNC Machine Data Collection? Computer Numerically Controlled (CNC) Machine Data Collection is about tapping into the rich vein of information that CNC machines generate during operation. It involves .

is a metal house cheaper than wood

JITbase gets data that no one has. Powered by machine data, JITbase automatically learns from CNC programs to get accurate cycle times for all machining and manual operations in addition to machine uptime tracking.For manual data collection, MDC-Max provides an operator interface for PC and mobile devices. It also comes with full support for barcode readers. Enables operators to access vital information and enter reasons for downtime, scrap, .The solution is collect & analysis data for CNC machine. It make equipment management to easy , transparency of production data and provides real time data of production. Automatically presents the efficiency of process, .Predator MDC includes automatic data collection interfaces including MTConnect, FANUC FOCAS, FANUC Robot, Okuma THINC, OPC, Haas, and XML. 20 different methods of data collection provide enough flexibility to support every .

is monel the most widely fabricated metal after steel

Predator MDC is real-time machine monitoring software that automatically collects, reports, charts and processes real-time shop floor manufacturing data including OEE, cycle time, idle time, setup time, teardown time, machine downtime and more.

Using Machine Data to Drive Factory Floor Optimization. Automated manufacturing equipment (CNC machines if you will), and the people who operate this equipment, are the beating heart of any manufacturing operation and represent one of the largest capital expenses for manufacturers.Our fully automated CNC machine monitoring software provides visualizations of real-time manufacturing production data, instant notifications, as well as historical analytics, allowing factory workers to make faster and smarter decisions based on their true productivity.A CNC machine monitoring system collects data from each machine control and operator, secures the data via an onsite IoT Gateway, provides access to the data via a mobile-friendly cloud application, visualizes the data using real-time dashboards, monitors machine conditions and production, analyzes the data using robust reporting features, and .By automatically detecting nearby employees, machine tools, and jobs, Harmoni automates unproductive data collection and production tasks, all while eliminating potential mistakes and human error.

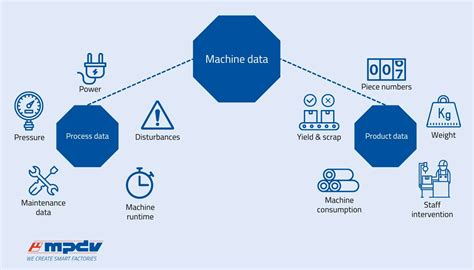

What is CNC Machine Data Collection? Computer Numerically Controlled (CNC) Machine Data Collection is about tapping into the rich vein of information that CNC machines generate during operation. It involves capturing, analyzing, and leveraging data to refine and enhance manufacturing processes.

JITbase gets data that no one has. Powered by machine data, JITbase automatically learns from CNC programs to get accurate cycle times for all machining and manual operations in addition to machine uptime tracking.

For manual data collection, MDC-Max provides an operator interface for PC and mobile devices. It also comes with full support for barcode readers. Enables operators to access vital information and enter reasons for downtime, scrap, current job/operator/shift, and more. Can be customized and accessed with a mobile device or PC.The solution is collect & analysis data for CNC machine. It make equipment management to easy , transparency of production data and provides real time data of production. Automatically presents the efficiency of process, manpower, machines, materials for a unified management.

machine data collection system

machine data collection software

Predator MDC includes automatic data collection interfaces including MTConnect, FANUC FOCAS, FANUC Robot, Okuma THINC, OPC, Haas, and XML. 20 different methods of data collection provide enough flexibility to support every CNC machine, robot, PLC, and test stand on your shop floor.Predator MDC is real-time machine monitoring software that automatically collects, reports, charts and processes real-time shop floor manufacturing data including OEE, cycle time, idle time, setup time, teardown time, machine downtime and more.

Using Machine Data to Drive Factory Floor Optimization. Automated manufacturing equipment (CNC machines if you will), and the people who operate this equipment, are the beating heart of any manufacturing operation and represent one of the largest capital expenses for manufacturers.

machine data collection process

Our fully automated CNC machine monitoring software provides visualizations of real-time manufacturing production data, instant notifications, as well as historical analytics, allowing factory workers to make faster and smarter decisions based on their true productivity.A CNC machine monitoring system collects data from each machine control and operator, secures the data via an onsite IoT Gateway, provides access to the data via a mobile-friendly cloud application, visualizes the data using real-time dashboards, monitors machine conditions and production, analyzes the data using robust reporting features, and .By automatically detecting nearby employees, machine tools, and jobs, Harmoni automates unproductive data collection and production tasks, all while eliminating potential mistakes and human error.

What is CNC Machine Data Collection? Computer Numerically Controlled (CNC) Machine Data Collection is about tapping into the rich vein of information that CNC machines generate during operation. It involves capturing, analyzing, and leveraging data to refine and enhance manufacturing processes.

JITbase gets data that no one has. Powered by machine data, JITbase automatically learns from CNC programs to get accurate cycle times for all machining and manual operations in addition to machine uptime tracking.For manual data collection, MDC-Max provides an operator interface for PC and mobile devices. It also comes with full support for barcode readers. Enables operators to access vital information and enter reasons for downtime, scrap, current job/operator/shift, and more. Can be customized and accessed with a mobile device or PC.

The solution is collect & analysis data for CNC machine. It make equipment management to easy , transparency of production data and provides real time data of production. Automatically presents the efficiency of process, manpower, machines, materials for a unified management.

is cricut a cnc machine

is a pull box a junction box

Beetle metal parts (51) Wolfparts and MetalRestoration was founded in 2003. We are a company that have specialized in old Volkswagens and high quality panels/parts that are so important for accomplishing a serious restoration.

automatic cnc machine data collection|cnc data collection software