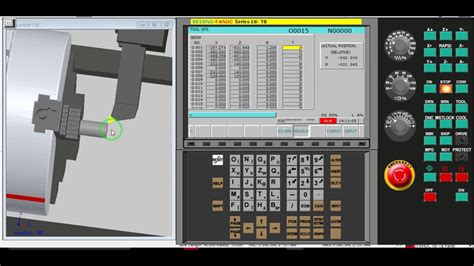

cnc machine tools and part programming CNC programming for beginners can be simplified into six key steps: familiarize yourself with the machine and its capabilities, create or obtain a detailed 3D model of the part, generate the toolpath using CAM software, write . Electrical boxes encase wire connections to protect them from short circuits. They are vital for fire safety and are used for receptacles, ceiling fans, outside outlets, and more. Unless the device is one of the few that contains its own wires, it likely will need an electrical box.

0 · manual programming cnc

1 · manual cnc programming for beginners

2 · how to write cnc code

3 · cnc programming for beginners pdf

4 · cnc programming examples

5 · cnc machine tool programming

6 · cnc lathe programming for beginners

7 · basic cnc programming for beginners

Zone 22 - A location in which an explosive atmosphere in the form of a cloud of combustible dust in the air is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing .

CNC programming for beginners can be simplified into six key steps: familiarize yourself with the machine and its capabilities, create or obtain a detailed 3D model of the part, generate the toolpath using CAM software, write .1. Understand the Machine's Coordinate System. Before programming, familiarize yourself with the CNC machine's coordinate system, including the X, Y, and Z axes. This understanding is . CNC programming involves you or a fellow colleague using computer-aided manufacturing (CAM) software to convert a CAD file into a language that a CNC machine can read, whether it’s a cutting, milling, or . Learn about CNC programming and improve your skills with CNCCookbook's articles, tips, and resources for beginners and experienced machinists.

Part programming for nc machines - Download as a PDF or view online for free. . The control signals are augmented to actuate drive motors which in turn rotate the ball lead-screws to position the machine table. .

CNC MACHINE TOOLS.ppt - Download as a PDF or view online for free. . • The numerical data required to produce a part is provided to a machine in the form of a program, called part program or CNC program. • The program .Manufacturing Technology: Unit V: Programming of CNC Machine Tools solved anna university problems on part programing Programming of CNC Machine Tools - Manufacturing Technology

low voltage line voltage junction box

manual programming cnc

Machine tool (lathe, drill press, milling machine etc) The part program is a detailed set of commands to be followed by the machine tool. Each command specifies a position in the Cartesian coordinate system (x,y,z) or motion (workpiece travel or cutting tool travel), machining parameters and on/off function. . (CNC) machine tools to improve .MANUAL PART PROGRAMMING. To prepare a part program using a manual method, the programmer writes the machining instructions on a special format called part programming manuscript. The programmer first prepares the program manuscript in a standard format.Computer Numerical Control (CNC) is a method of automating control of machine tools through the use of software embedded in a microcomputer attached to the tool.With CNC, each object to be manufactured gets a custom computer program, usually written in an international standard language called G-code, stored in and executed by the machine control unit(MCU).The . Now that we have covered the basics of CNC programming, let’s dive into the step-by-step process of creating a CNC program. Step 1: Design the Part. The first step in CNC programming is to design the part using CAD software. This involves creating a 3D model of the part, specifying its dimensions, and incorporating any necessary features or .

CNC Machines and CNC Programming: Set foot in any of the modern manufacturing companies, and you’ll find a number of CNC machines. Computer numeric control (CNC) machines, crucial for machining and automation, have become an important part of the manufacturing industry. . This software allows machine tool operators to create part programs . CNC programming is at the heart of modern manufacturing, allowing machines to transform raw materials into precise, detailed components. G and M codes are the essential languages that guide these machines, setting the paths and controls to shape, cut, and craft parts with impressive accuracy.. Thanks to G and M codes, manufacturers can achieve unmatched .

of the CNC machine tools. 4.2 PART PROGRAMMING FUNDAMENTALS As discussed earlier, the numerical control machine tools require a part program to generate the requisite geometric shape of the components. The part program is basically a detailed step-by-step procedure that gives the necessary instructions to the various parts of a CNC machine tool .This text-book explains the fundamentals of NC/CNC machine tools, operations and part programming which form essential portion of course on Computer Aided Manufacturing (CAM). This book also covers advanced topics such as Macro programming, DNC and Computer Aided Part Programming (CAPP) in detail. . Translation of the tool paths to a part .

A program defining motion of tool / workpiece in this coordinate system is known as a part program. Lathe and Milling machines are taken for case study but other machine tools like CNC grinding; CNC Hobbing, CNC filament winding machine, etc. . Features of CNC Machines • The tool or material moves. • Tools can operate in 1-5 axes. • Larger machines have a machine control unit (MCU) which manages operations. . Basics of CNC Programming • CNC instructions are called part program commands. • When running, a part program is interpreted one command line at a time until all .

A CNC machine that operates on wood CNC machines typically use some kind of coolant, typically a water-miscible oil, to keep the tool and parts from getting hot. A CNC metal lathe with the door open.. In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] It is used to operate tools such . Also it consists of monitor, feather touch keyboard, machine control panel. q Schematic diagram of a CNC machine tool 6Dr.S.Cartigueyen 7. Working . Storage of more than one part program - CNC machine can store multiple .The Machine Tool Technics Technical Diploma prepares learners to set up and operate various types of manual and computer numerical controlled (CNC) machine tools. Learners machine piece parts, use precision measuring tools .

Top 10 AI Tools for CNC Machining Programming in 2024. In light of these applications, here are the top 10 AI tools that are currently leading the way in CNC machining – these cover CAD, CNC programming, G-Code . 11. • By integrating a computer processor, computer numerical control, or “CNC” as it is now known, allows part machining programs to be edited and stored in the computer memory as well as permitting diagnostics and quality control functions during the actual machining. • All CNC machining begins with a part program, which is a sequential instructions or coded .Once the workplace is securely clamped in the vice, the operator jogs the machine to set the _____. - reference zero - part zero - machine zero - home position commands CNC programming language provides _____ the user chooses to create a part program. - directions - commands - subroutines - macros A CNC machine tool always has a sliding table and a spindle to control the position and speed. The table of the machine is controlled in the X and Y-axis direction and the spindle is controlled in the Z-axis direction. . These are devices that are used to input the part program into a CNC machine. There are three generally used input devices .

This automated parts carousel not only catches and collects machined parts from a CNC machine tool but also sorts the parts in bins attached to a rotating table. . New part programming developments continue to be added to the Tri-County Technical College curriculum and solutions for Swiss-type lathes might soon be included.16 In CNC machine tool, the part program entered into the computer memory A can be used only once. B can be used again but it has to be modified every time. . The control unit of NC machine tool works in batch processing mode and the control unit of CNC machine tool works in ON-line mode 18 In NC (Numerical Control) machine tool, . Explore the world of CNC Programming with our comprehensive guide to CNC Programming Languages. . tangible parts with precision. G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool motion, while M Code manages machine operations like spindle activation and coolant flow .

CNC part Programming : The part programming contains the list of coordinate values along the X, Y and Z directions of the entire tool path to finish the component. . The most common codes used when programming NC machines tools are G-codes (preparatory functions), and M codes (miscellaneous functions). Other codes such as F, S, D, and T are .CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such as cutting, milling, and drilling. CNC programming involves writing a series of commands, typically in the form of a . How Does CNC Programming Work? CNC programming involves converting a design or blueprint into a set of instructions that CNC machines can interpret and execute. The process begins with creating a part design using Computer-Aided Design (CAD) software, followed by translating that design into commands via Computer-Aided Manufacturing (CAM) .

APT programming language is a language for defining tool paths on CNC machines. APT is an acronym for Automatically Programmed Tool. . that is understood by the machine. You feed the NC program into the machine and cut the part. APT programming language example for milling around a part $$ PART SHAPE DEFINITION. STRT = POINT/ .

lowes metal corner bracket 4x4

manual cnc programming for beginners

lowes ceiling fan box metal

how to write cnc code

LOCATOR Attachment System is the most globally recognized and trusted brand for overdenture restorations. Combining innovative patented technology with availability in more than 280 .

cnc machine tools and part programming|cnc machine tool programming