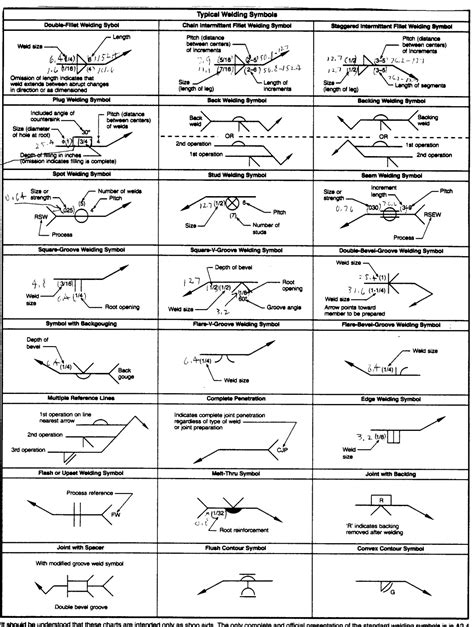

sheet metal seam weld symbol Welding symbols are the integral part and the basic requirements for fabrication as they provide vital information for the welding joint location, weld size (throat or leg length, depth of penetration) & length, weld type & quality .

You will not have a real TIG welder, but after some practice with scratch starting the arc, you can weld thin steel with far better results. You can even weld 24 gauge (0.5 mm) sheet metal. Furthermore, if your stick welder has a lift-start ignition, you can use it for easier arc start and grinding the tungsten electrode less often.

0 · welding symbols on drawings

1 · welding symbol length and pitch

2 · weld symbol chart and meaning

3 · weld symbol calculator

4 · types of seam welding

5 · stitch welding symbols on drawings

6 · seam weld vs fillet

7 · seam weld vs butt

$199.00

how much to metal roof your house

welding symbols on drawings

One of these symbols is the seam welding symbol, which tells welders to join two metals together along a continuous line. In this blog, we will explain what the seam welding symbol is, how it works, and how to use it in engineering drawings and blueprints.Seam Weld Symbol. Description: Represents a seam weld, which is a . Welding Symbol for Seam weld. A seam weld joint is made between two faying surfaces using a lap joint configuration. Seam Weld symbol is a no arrow or other side .

welding symbol length and pitch

During metal joining processes, weld symbols are meant to indicate different parts of the process. These symbols are usually found in fabrication and engineering drawings. A .

An example of a seam weld: Seam welds will have a size or shear strength associated with the welding symbol commonly. This number will go to the left of the welding symbol. A size is an indication of width of the bead. Shear . Welding symbols are the integral part and the basic requirements for fabrication as they provide vital information for the welding joint location, weld size (throat or leg length, depth of penetration) & length, weld type & quality .

The weld symbol distinguishes between the two sides by using the arrow and the spaces above and below the reference line. The side of the joint to which the arrow points is known as the arrow side, and that weld's instructions . Table of Contents show. Resistance Spot Weld Symbol. Resistance spot weld symbols have no arrow or other side significance in themselves, although supplementary symbols used in conjunction with them .

Seam Weld Symbol. Description: Represents a seam weld, which is a continuous weld along the length of a joint. Example: This type of weld can be made using a resistance spot welder, which is often used in sheet metal work. . See also Seam Welding Symbol: Complete Guide. Spot welding applications. Spot welding is commonly used in . A CJP weld is also a 100% weld and requires clean, effective weld metal to penetrate the entire weld joint, leaving no seam or gap between the plates. To indicate a CJP weld, the engineer will put “CJP” in the tail of the . Weld symbols play a crucial role in sheet metal fabrication, enabling effective communication between designers and welders. . it is used to represent a weld made in the corner formed by two pieces of metal. Edge .

Description: Represents a plug weld, which is a weld made by filling a hole with weld metal. Example: Seam Weld Symbol. Description: Represents a seam weld, which is a continuous weld along the length of a joint. . a good welding symbol cheat sheet can be a lifesaver when interpreting blueprints. It condenses pages of standards down to one . Preparation: Clean the Metal: Before you begin welding, the surfaces of the metals should be clean.Use a wire brush or grinder to remove any rust, paint, or other contaminants from the surface. Align the Edges: The two pieces of metal should be aligned along their edges.They should be touching, but a small gap (approximately 1/16″ to 1/8″) can help achieve a better .Study with Quizlet and memorize flashcards containing terms like Welding Symbols, the top and the bottom, Symbols and more. . seam welding _____ used to join two pieces of sheet metal in a continuous seam or in a series of overlapping spot welds. About us. . Open corner weld joints are useful for welding thin sheet metal or gauge sheets. This is also called corner-to-corner joint. Open corner joints are difficult to position (fitment) and hence requires use of fixturing. . An open corner has a fillet weld symbol, while a closed corner has either a groove or fillet weld symbol. The size and number .

A Guide to Welders About Welding Symbols Introduction Welding is an intricate craft, blending both art and science. . or an elongated rectangle (for slot welds) placed on the reference line. These welds are typically used in sheet metal work and automotive industries. 6. Spot Weld Symbol. . Seam Weld Symbol. Seam welds create a continuous .9. Spot, Seam, Stud Welding Symbols 67 10. Edge Weld Symbols 77 11. Process and Method 83 12. Pipe Symbols 87 13. Pipe Drawings 92 . Interpreting metal fab drawings. . sheet metal industry the corner joint is used on the outer edge of the piece. This weld is a type of joint that comes together atLooking for help interpreting the welding symbol below. It is for a seam weld on a rolled stainless steel sheet metal cylinder . Trying to understand the symbol above and below the contour lineWelding Symbols. Flashcards; Learn; Test; Match; Q-Chat; Get a hint. . seam weld. Symbol consists of a circle & 2 intersecting lines parallel to the reference line. Weld is lengthwise joining adjacent/overlapping sheet metal ends. stud weld. Consists of a circle with an X in the middle of it. Weld joining a threaded stud to a workpeice

A flare V groove weld is often used in sheet metal for connecting flanges: Back Welds and Backing Welds What is a Back Weld? A back weld is the weld applied after the main groove weld. . The symbol for a seam weld is a circle with two horizontal lines going through it: .

The symbols, in particular for arc and gas welding, are often shown as cross-sectional representations of either a joint design or a completed weld. Simple, single edge preparations are shown in Fig. 5. For resistance welding, a spot weld and seam weld are shown in Fig. 6: Butt Weld Symbols Butt weld symbols provide crucial information about the joint design, welding processes, and other essential details necessary for successful welding operations. . For sheetmetal, square groove are most used as it is easy to fuse sheet metal. For higher thickness, square groove is used with high density energy processes such .

During metal joining processes, weld symbols are meant to indicate different parts of the process. . You will see this symbol when the sheet metal is being welded, and there is a melt-through in the joints and seams. .The weld is for the corner of effectively a sheet metal picture frame. The second image shows the corner of the flat sheet pattern. The intent of the weld is to hide the seam of the two edges, and provide some structure. I understand the underscore underneath is to have it flat finished, but I've never seen the т г symbol before. Any thoughts?Steel Sheet Punching Vector Icon Design, Arc welding equipment and Metal Work Symbol on white background, Construction and Industrial manufacturing Sign, Welding press machine Concept . welding seam onto aluminum sheet . Resistance seam welding: Electric current is passed through the metal parts to generate heat and melt the seam. This is a common technique for welding sheet metal components. Friction seam welding: High rotational speeds and pressure are used to generate heat and weld the seam through friction. This technique is often used for tubular metal parts.

The size of a Square Groove Weld is equal to the base metal thickness (t), e.g. a plate of 1/8 inches thickness made with a Square Groove Weld will have a weld size (s-throat size) of 1/8 inches.. The excess root penetration or excess weld face reinforcement is not considered for a Square Groove Weld Size. Square Groove Weld Example. Square groove . Chapter #6 – Sheet Metal Seams. Seams run longitudinal along the length of the duct run, while joints run transverse (across). Seams run parallel to the air flow, while joints are perpendicular to the air flow. The seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces together.

weld symbol chart and meaning

These welds are commonly used in the automotive and sheet metal fabrication industries due to their speed and efficiency. . Slot, Arc Spot, Arc Seam, Resistance Spot, Resistance Seam, and Projection Welding Symbols, where the arrow connects the welding symbol reference line to the outer surface of one member of the joint at the center line of .

weld symbol calculator

First create a sheet metal part. If needed a flat panel layout (not really necessary). Save the part. Open a new weldment Assembly. Place the sheet metal part into the assembly. More than likely you'll want to use the "goove" option to fill in the gaps. I would tend to believe that the same option would apply if joing two sheet metal pieces . The symbol for a seam weld is two parallel lines placed across a circle. 5. Spot or Projection Weld . a tool commonly used in sheet metal work. . The edge welding symbol is used in welding to indicate that two pieces of metal will be joined by a weld along their edges. It is typically represented by two rectangles placed on the reference line.Search 'ANSI Weld Symbol Library' in the SOLIDWORKS Knowledge Base. Provide feedback on this topic SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation.

Welding is a technique used in sheet metal fabrication where weld symbols are used to enable designers to communicate with coded welders by placing welding information onto drawings.. Welding Standards. EN ISO 2553:2013 is the British standard for weld symbols which provides the rules for the symbolic representation of welded, brazed and soldered joints on drawings.

how much to replace electric panel box

Its symbol is a circle, the same shape as a spot weld. Resistance seam. This is like a resistance spot weld, only the electrical resistance creates a long seam weld rather than a single spot. Similar to the spot welds symbol, the seam weld has two parallel lines through the circle symbolizing the seam weld having length like a slot shape. 1.9: Spot, Seam, Stud Welding Symbols Expand/collapse global location 1.9: Spot, Seam, Stud Welding Symbols . When there is no side significance this can commonly be applied using a resistance spot welder which is used widely in sheet metal work. A spot weld is simple a weld applied to the surface of one member that has enough heat input to .

how much to replace electric panel box in pa

CNC machine pricing varies widely, typically ranging from $5,000 to $200,000 or more, depending on factors such as size, complexity, and capabilities. Entry-level desktop CNC machines suitable for hobbyists or small businesses can cost between $5,000 and $20,000.

sheet metal seam weld symbol|welding symbol length and pitch