what is a sheet metal pattern A sheet metal development serves to open up an object that has been rolled, folded, or a combination of both, and makes that object appear to be spread out on a plane or flat surface. . A crucial tip for welding galvanized steel is to use the correct weld joint design and method of application. You can use the Gas Metal Arc Welding (GMAW), Flux Core Arc Welding (FCAW) techniques. One of the most .

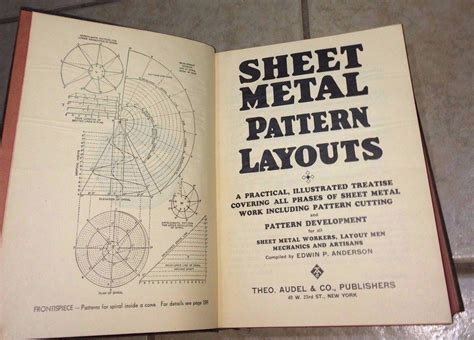

0 · sheet metal pattern layouts pdf

1 · sheet metal pattern layout methods

2 · sheet metal layout pdf

3 · sheet metal drawing easy

4 · free sheet metal layout patterns

5 · free sheet metal layout books

6 · decorative pierced metal sheets

7 · decorative perforated metal sheets

Top 10 Best Welding and Metal Services in Virginia Beach, VA - August 2024 - Yelp - Production Welding & Fabricating, Miller's Garage, Industrial Alloy Welding, Colonial Metal Works, Dozier Tank & Welding, AAA Welding & Repair, Hot Rod Welding Service, Standard Welding, Dyson Mechanical, Metal Designs

Triangulation is a practical approach to pattern development. Developing patterns is an essential part of sheet metal work. This is an introduction to the process. You will find many uses. K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to .The process of pattern development gives us the ability to take that visual representation and actually create the object. It allows us to turn two-dimensional metal, into three-dimensional .A sheet metal development serves to open up an object that has been rolled, folded, or a combination of both, and makes that object appear to be spread out on a plane or flat surface. .

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different .Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf , and pieces thicker than 6 mm (0.25 in) are considered plate, such as . Pattern Development: Sheet Metal Level 1. Line E. Brian Coey. Download this book. This book covers all three forms of layout as well as geometric construction. It introduces the learner to the techniques used in .The process of pattern development is the way we turn 2D sheets of metal into 3D objects. A parallel line is one of the basic forms of layout. We use it when element lines (bends) on an .

The problem, as seen in the third screenshot, is that the flat pattern created from the converted sheet metal parts are not flat. Somewhere along the way, fusion fails to fully flatten the curved section, as seen by the shadow it leaves in the .Flat Pattern is nothing but unfolded shape of any sheet metal shapes or fabrication shapes before forming processes such as Bending, Rolling, etc. We can also say that Flat pattern is a pre or raw flat surface before forming activity in sheet metal or fabrication Industry.Sheet metal fabrication is a multifaceted manufacturing process that involves the shaping, cutting, and assembling of metal sheets to create a wide range of custom components. . This method is precise and efficient, making it ideal for .Various methods for layout. The tape method is supposed to work well for round objects and can be turned inside out to create a mirrored part.

wholesale customized cnc turning parts

K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. In this article, we will discuss sheetmetal bend deduction, bend allowance, K-factor, Y-factor, and sheet metal flat pattern calculations.Here list the main patterns of decorative metal sheets, including standard and ornamental designs. We will keep updating it. Triangulation is a practical approach to pattern development.Developing patterns is an essential part of sheet metal work. This is an introduction to the pro.

It introduces the learner to the techniques used in parallel line, radial line, and triangulation. With videos and animations, the learner has an opportunity to play, pause, and rewind as they practice these techniques. This book covers material required for a level 1 sheet metal apprentice (Line E). Hello All, I have a simple sheet metal part that does not require explicit bend radii. We leave it up to the shop to fab this part up as long as it's final outcome is within tolerance. We don't normally include a flat pattern, simply because it could cause confusion when cutting a blank. I use the default bend allowance and bend radius, which gives the exact blank size and .A Flat Pattern is the shape of the sheet metal component before it is formed. Folded sheet metal body Flat pattern view; Flat patterns show bend lines, bend zones, center lines, and the shape of the entire sheet metal body with all bends flattened and bend factors considered.

A Flat Pattern is the shape of the sheet metal component before it is formed. Folded sheet metal body Flat pattern view; Flat patterns show bend lines, bend zones, center lines, and the shape of the entire sheet metal body with all bends flattened and bend factors considered.

Sheet metal fabrication and its intricate processes are always in my mind when I reflect on our experience at Shengen.Sheet metal stamping is one of the techniques crucial to our success. We’ll explore this vital technique together. The sheet metal stamping process is where metal sheets can be shaped and sized to the desired shape or size by applying an external force. Perforated Sheet Patterns. Perforated sheet is a special form of sheet that has a pattern of shapes removed from it. Perforated sheet provides various benefits when compared with regular sheet.The perforation patterns allow for the sheet to be lighter, provide more traction for pedestrians, and let water or other liquids pass through them rather than accumulate.Pattern Development: Sheet Metal Level 1. Introduction When wanting to build a project, we need to first imagine it. The process of pattern development gives us the ability to take that visual representation and actually create the object. It allows us to turn two-dimensional metal, into three-dimensional objects, which is the basis for . I know it's an old problem but, did anyone actually find a solution that doesn't involve playing around with code, re-writing bend tolerances or reinventing the K-Factor? I have a simple steel pipe in sheet metal that I have .

Pattern book (English) 20+ Patterns; Sheet metal and band cut charts; Insulation miter cut charts; 90°& 45° prefabed size charts; Letter charts for insulation corresponding to the WH Ruler.Sheet metal patterns are also known as _____. prism and cylinder _____ and _____ are examples of the parallel-line pattern developments. pyramid and cone _____ and _____ are examples of the radial-line pattern development. Used to connect two differently shaped openings. What purpose does a transition piece serve? . Is there a standard for proper dimensioning of features in a flat pattern sheet metal drawing view? Is there a standard way to list bend allowance/K factor, or is this something that isn't defined to well and varies a bit more from company to .

sheet metal pattern layouts pdf

sheet metal pattern layout methods

Hi! It depends on when the cut is made. If the cut nees to be made when the sheet metal part is flattened, guido66 is correct. Just do Unfold on the Folded part and then make the cut when the sheet metal part is flattened. Then do Refold to fold the part back.From creating 2D patterns of 3D objects, to making sure roof panels are installed square, to locating duct runs and penetrations, geometry is used everyday by a sheet metal worker. This is the foundation for which all layout is done.Use the elbow rule (# of pcs × 2 − 2) to find the number of gores.For our example, it is 4 × 2 − 2 = 6.Each end piece is made up of 1 gore and each middle piece is made up of two gores.; Use the angle of the elbow divided by the number of gores to find the miter angle. In our case, 90° ÷ 6 = 15°. Now that we know the miter angle is 15°, we can use an end gore and lay it out similar .

I was given a stack of 24" x 36" sheets from an old school sheet metal guy a few years back and haven't been able to find a good resource for it since. . for patterns, and fortunately the proprietor (old fashioned word for the knowledgeable guy that works there) is an older guy. '46SuperDeluxe, Sep 9, 2010. SHARE POST #23. Joined: Sep 20 .Perforated metal refers to sheet metal that has been stamped, punched, or otherwise fabricated to create a pattern of holes, slots, or decorative shapes. This process can involve various metals, including steel, aluminum, stainless steel, copper, and titanium.

Sheet metal is used to make patterns for many objects. The metal is shaped by bending (see Figure 14-4), folding, or rolling and fas-tened by riveting, seaming, soldering, or weld-ing. For each sheet-metal object, two drawings are usually made. One is a pictorial drawing of the fi nished product, and the other is a devel-opment, or pattern .Pattern Development: Sheet Metal Level 1. Triangulation When we looked at both parallel line and radial line pattern development, we saw fairly simple and limited layout process. We have conditions that must be met in order to use them. Triangulation is the process used when nothing else works. There are very few conditions in which .

i worked at a large company with a world-class sheet metal manufacturing plant attached. we were required to provide a flat pattern view with each sheet metal drawing, but dimensions were not required. the purpose here was to "prove" that the part in the drawing could be made from a single non-overlapping sheet of metal. basically it was a .need help manufacturing sheet metal? want to post your fabrication for all to updoot? come to r/sheetmetal to discuss all things sheet metal. Design, Fabrication, Installation. . x2-2} = 11.25. This is the bottom half gore that we develop the pattern for. This pattern is doubled over on the straight side to make the larger center gores. Hope .

wholesale customized sheet metal fabricating

I need to put an outlet here on this metal pole in my basement. Are there any special brackets to use?

what is a sheet metal pattern|sheet metal layout pdf